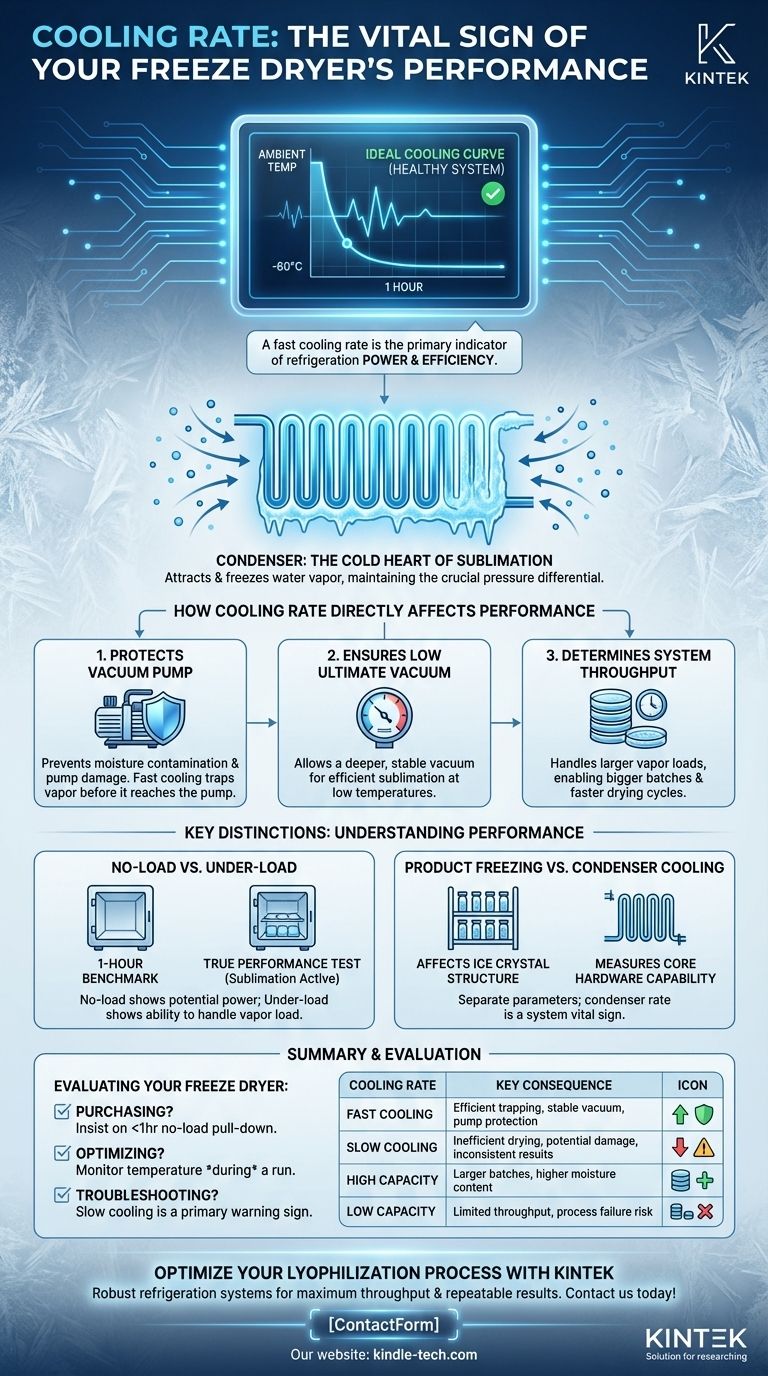

At its core, cooling rate is the primary indicator of a freeze dryer's refrigeration power and efficiency. It directly reflects the system's capacity to get the cold trap (or condenser) to its operational temperature. A fast and powerful cooling system is fundamental to the entire lyophilization process, as it dictates the machine's ability to efficiently capture water vapor.

A freeze dryer's cooling rate is more than just a measure of speed; it's a critical benchmark of the system's capacity to handle a vapor load. A robust refrigeration system ensures efficient sublimation, protects the vacuum pump, and is ultimately essential for successful and repeatable results.

The Central Role of the Condenser

To understand the impact of cooling rate, you must first understand the function of the condenser, often called the cold trap. This is the coldest point in the freeze dryer and is the heart of the sublimation process.

Why the Condenser is Critical

The condenser's sole purpose is to attract and freeze water vapor molecules that leave your product during the drying phase. It acts as a powerful vapor pump.

By creating an extremely cold surface, the condenser maintains a pressure differential between it and the product. This pressure gradient is the driving force that pulls water vapor from the product and traps it as ice on the condenser coils.

Cooling Rate as a Measure of Power

The speed at which the condenser reaches its minimum temperature under no-load conditions is a direct measure of the refrigeration system's raw power.

A common industry benchmark, as noted in performance specifications, is for the condenser to reach its target temperature (e.g., -60°C) within one hour of a cold start. A system that achieves this demonstrates it has a healthy and capable refrigeration circuit.

Impact on Sublimation Efficiency

A more powerful refrigeration system not only gets cold faster but can also handle a higher "vapor load" during the primary drying phase.

When sublimation begins, a massive amount of water vapor floods the system. A robust condenser has the cooling capacity to trap this vapor rapidly, keeping the system pressure low and the sublimation process running efficiently.

How Cooling Rate Directly Affects Performance

A freeze dryer is an interconnected system. The performance of the refrigeration circuit has direct consequences for other critical components and the overall process outcome.

Protecting the Vacuum Pump

This is arguably the most critical function. If the condenser is not cold enough or lacks the capacity to trap incoming vapor, that moisture will bypass the condenser and travel directly into the vacuum pump.

Water vapor contaminates pump oil and can cause severe, costly damage to the pump. A fast, powerful cooling system is the primary line of defense for this essential component.

Ensuring a Low Ultimate Vacuum

The vacuum pump's job is to remove non-condensable gases (like air), not water vapor. The condenser is responsible for removing the water vapor.

An efficient condenser that rapidly traps moisture allows the vacuum pump to achieve a deeper, more stable vacuum level. This low pressure is essential for sublimation to occur at low temperatures, which protects the integrity of your product.

Determining System Throughput

A system with a higher refrigeration capacity (indicated by a faster cooling rate) can handle a larger volume of water vapor over a given period.

This means it can process larger batches, dry products with higher moisture content, or potentially complete drying cycles faster, directly impacting your lab's or facility's throughput.

Understanding the Key Distinction

It's crucial to differentiate between two types of performance: how a machine acts when it's empty versus how it acts when it's working.

No-Load vs. Under-Load Performance

The one-hour pull-down time is a no-load benchmark. It tells you the system is healthy and has potential power.

However, the real test is its performance under load, when sublimation is active. A system that cools fast when empty but struggles to keep its condenser cold during a run indicates it is being overwhelmed by the vapor load. True performance is measured by the ability to maintain temperature while actively trapping water.

Product Freezing vs. Condenser Cooling

The term "cooling rate" can also refer to the rate at which the product itself is frozen on the shelves. This is a separate, though important, process parameter that affects the product's ice crystal structure.

The focus here is specifically on the condenser's cooling rate, which is a measure of the machine's core hardware capability, not a process variable you typically adjust.

Evaluating a Freeze Dryer's Cooling Performance

Use the cooling rate as a key performance indicator to assess the health and capability of your equipment.

- If you are purchasing new equipment: Insist on seeing the no-load condenser pull-down time. A machine that meets or exceeds the one-hour benchmark has a powerful refrigeration system.

- If you are optimizing an existing process: Monitor the condenser temperature during a run. A steady, low temperature indicates the system is handling the load, while a rising temperature suggests you may be overwhelming its capacity.

- If you are troubleshooting failures: A slow condenser cooling rate or an inability to reach the target temperature is often the first sign of a refrigeration system issue that requires professional maintenance.

Ultimately, a freeze dryer's cooling rate is the vital sign of its core capability: to effectively remove water vapor and ensure the success of your entire lyophilization process.

Summary Table:

| Cooling Rate Impact | Key Consequence |

|---|---|

| Fast Cooling | Efficient vapor trapping, stable vacuum, protects pump |

| Slow Cooling | Inefficient drying, potential pump damage, inconsistent results |

| High Refrigeration Capacity | Handles larger batches, higher moisture content |

| Low Refrigeration Capacity | Limited throughput, risk of process failure |

Optimize Your Lyophilization Process with KINTEK

Does your freeze dryer struggle with slow cooling or inconsistent performance? A powerful refrigeration system is the heart of efficient and reliable freeze drying. KINTEK specializes in high-performance lab equipment, including freeze dryers with robust cooling systems designed to protect your samples and your vacuum pump, ensuring maximum throughput and repeatable results.

Contact us today to discuss your laboratory's needs and discover how our solutions can enhance your freeze-drying efficiency and protect your investment.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the purpose of an evaporator? The Key Component That Creates Cooling

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure