At its core, freeze-drying is a high-fidelity preservation method. While commonly associated with things like astronaut food, its most critical applications are found in pharmaceuticals, high-end food production, and sensitive scientific research. The process, also known as lyophilization, is used to stabilize drugs and vaccines, preserve the nutrients and flavor of premium foods, and maintain the integrity of biological samples for long-term storage and analysis.

Freeze-drying's unique value is its ability to remove water without destroying a material's delicate internal structure. By converting ice directly into vapor—a process called sublimation—it preserves the biological activity, chemical stability, and physical form of substances that would be ruined by conventional heat-based drying.

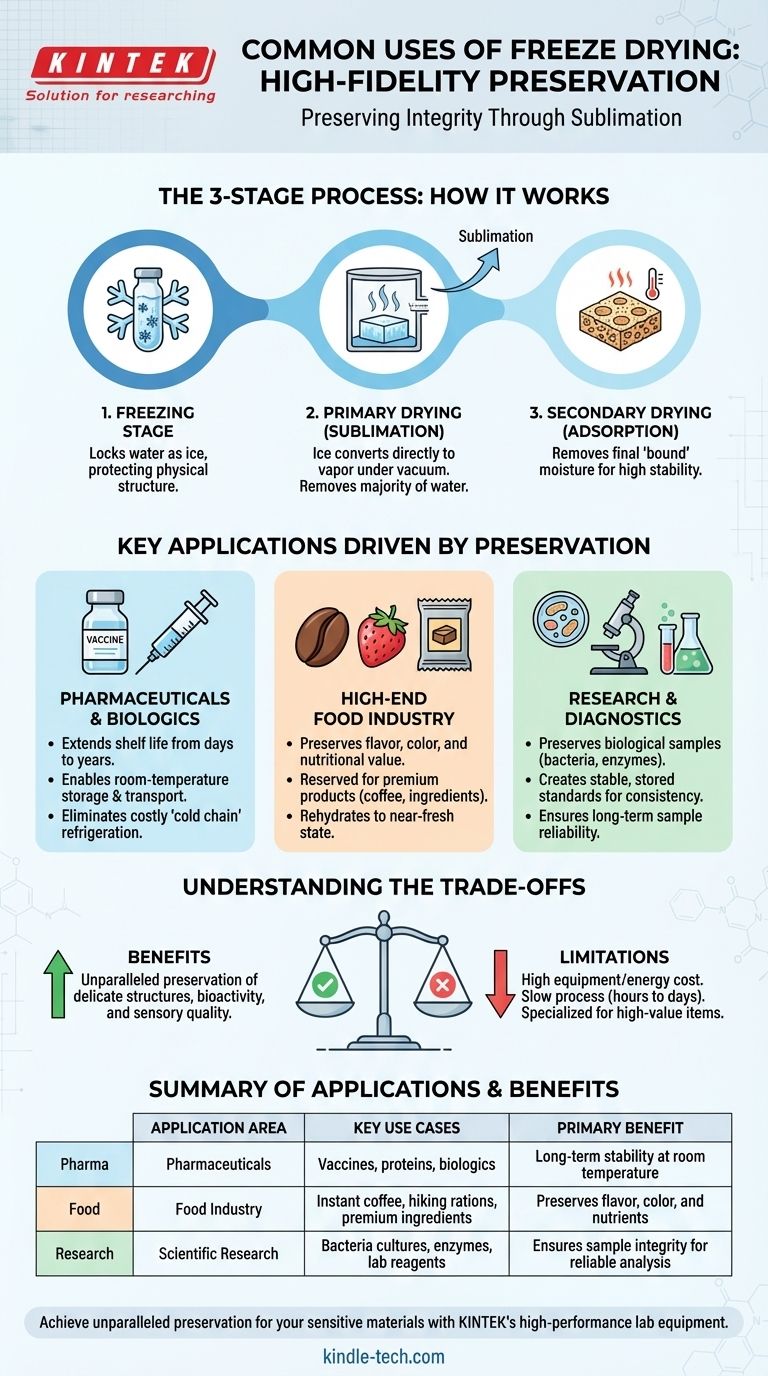

The Principle: How Freeze-Drying Works

To understand its applications, you must first understand the process. Freeze-drying is fundamentally different from simple dehydration because it avoids the destructive liquid water phase.

The Three Critical Stages

The process unfolds in three distinct steps.

-

The Freezing Stage: The material is completely frozen, typically to a very low temperature. This locks water molecules in place as ice crystals, protecting the product's physical structure.

-

Primary Drying (Sublimation): The pressure inside the chamber is dramatically lowered, creating a vacuum. A small amount of heat is applied, giving the frozen water molecules just enough energy to turn directly from solid ice into water vapor, which is then collected on a condenser. This removes the vast majority of the water.

-

Secondary Drying (Adsorption): After the free ice is gone, a small amount of "bound" water molecules may remain attached to the material. The temperature is gradually raised and the vacuum is intensified to remove this final bit of moisture, resulting in a highly stable, dry product.

Key Applications Driven by Preservation

The ability to gently remove water makes freeze-drying the only viable choice for many heat-sensitive and high-value materials.

Pharmaceuticals and Biologics

This is arguably the most critical application. Many modern drugs, especially biologics like vaccines, antibodies, and proteins, are unstable in liquid form.

Freeze-drying transforms them into a dry powder. This dramatically extends their shelf life from days to years and allows them to be stored and transported at room temperature, eliminating the need for a costly and complex "cold chain" of refrigeration.

High-End Food Industry

While most dried foods use heat, freeze-drying is reserved for premium products where quality is paramount. It preserves flavor, color, and nutritional value that other methods destroy.

Common examples include instant coffee, military or hiking rations, and high-value ingredients like fruits for cereals and herbs. When rehydrated, the product is remarkably close to its fresh state.

Research and Diagnostics

In labs, freeze-drying is essential for preserving biological samples. This includes bacteria cultures, enzymes, and other reagents used in diagnostics and research.

By lyophilizing these materials, researchers can create stable, easily stored standards that ensure consistency and reliability in their work over long periods.

Understanding the Trade-offs

While powerful, freeze-drying is not a universal solution. Its benefits come with significant costs and limitations that make it unsuitable for many common applications.

The Equipment and Time Cost

Freeze-drying equipment is complex and expensive. The process itself is also incredibly slow, with cycles often taking many hours or even days to complete. This makes it far more costly than conventional drying.

High Energy Consumption

Maintaining extremely low temperatures and a high vacuum requires a significant amount of energy. This contributes to the high operational cost and limits its use to products where the expense is justified by the final value.

A Highly Specialized Process

The precision required for freeze-drying makes it overkill for durable, low-value materials. It is a specialized tool reserved for substances that are delicate, unstable, or where perfect preservation is non-negotiable.

Making the Right Choice for Your Goal

Deciding to use freeze-drying depends entirely on whether the integrity of the material is your top priority.

- If your primary focus is preserving biological activity or molecular structure: Freeze-drying is the gold standard for maintaining the stability and efficacy of sensitive materials like vaccines, proteins, or lab reagents.

- If your primary focus is retaining sensory quality and nutrition: Use this method to create premium, shelf-stable food products that are nearly indistinguishable from fresh when reconstituted.

- If your primary focus is achieving maximum shelf-life and transportability: Freeze-drying is the ideal method for creating a product that is stable for years at ambient temperature, eliminating the need for refrigeration.

Ultimately, freeze-drying is the definitive solution for situations where the final quality and stability of the product cannot be compromised.

Summary Table:

| Application Area | Key Use Cases | Primary Benefit |

|---|---|---|

| Pharmaceuticals | Vaccines, proteins, biologics | Long-term stability at room temperature |

| Food Industry | Instant coffee, hiking rations, premium ingredients | Preserves flavor, color, and nutrients |

| Scientific Research | Bacteria cultures, enzymes, lab reagents | Ensures sample integrity for reliable analysis |

Ready to achieve unparalleled preservation for your sensitive materials? KINTEK specializes in providing high-performance lab equipment, including freeze-drying solutions, to meet the demanding needs of pharmaceutical, food, and research laboratories. Our expertise ensures your delicate products maintain their biological activity, stability, and quality. Contact our experts today to find the perfect freeze-drying solution for your application!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Hybrid Tissue Grinding Mill

People Also Ask

- Why are freeze-dried foods ideal for space missions? Solving the Critical Challenges of Space Logistics

- What is the rehydration capability of freeze-dried products? Achieve Superior Quality & Instant Restoration

- What role does freeze-drying play in biotechnology? Preserving Biological Integrity for Long-Term Stability

- What are the main components of a lab freeze dryer? Unlock the Secrets of Lyophilization

- What are the factors affecting evaporation? Control the Rate of Any Liquid's Vaporization