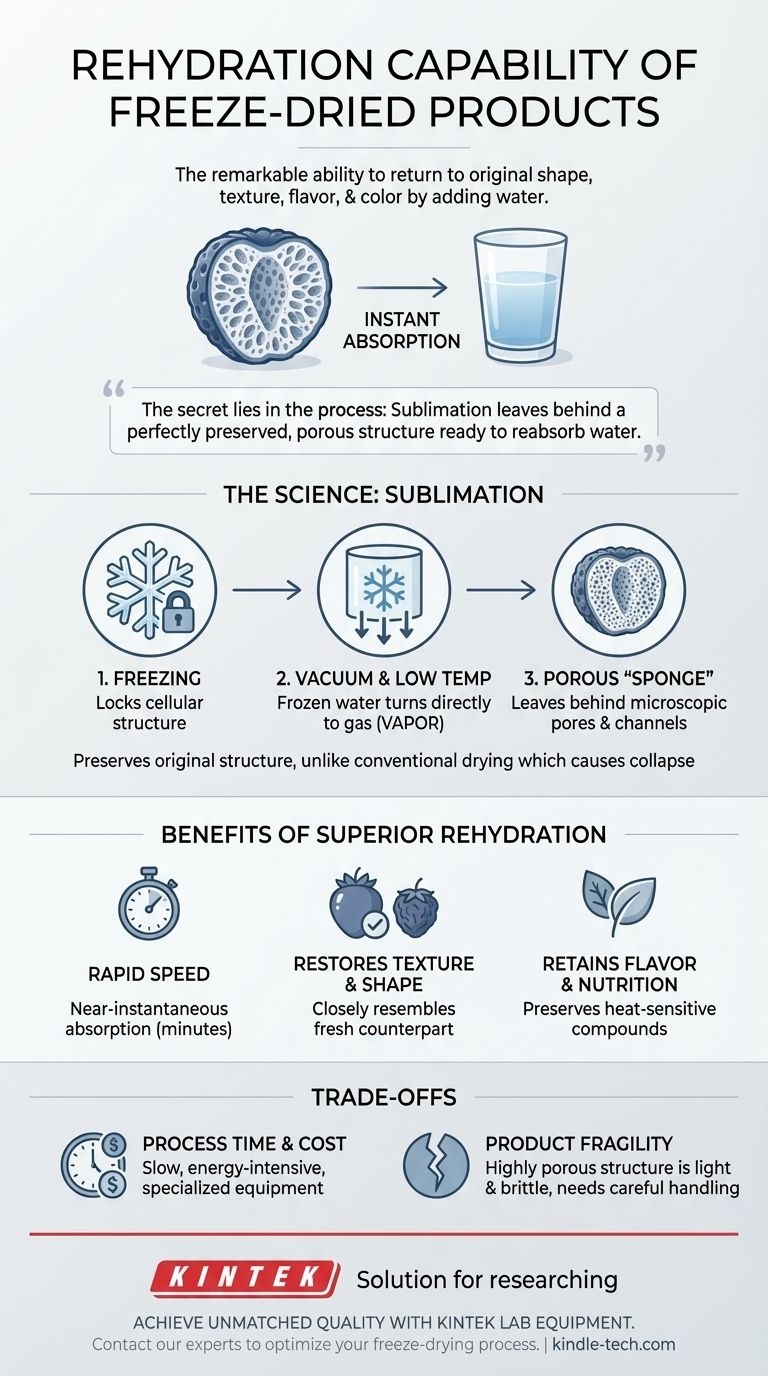

At its core, the rehydration capability of a freeze-dried product is its remarkable ability to return to its original shape, texture, flavor, and color with the simple addition of water. Because the freeze-drying process removes water without damaging the product's underlying structure, it can be restored with an integrity that other drying methods cannot match.

The secret to the exceptional rehydration of freeze-dried products lies in the process itself. By turning ice directly into vapor (sublimation), it leaves behind a porous, sponge-like structure that is perfectly preserved and ready to reabsorb water instantly.

The Science Behind Superior Rehydration

To understand why freeze-dried products rehydrate so well, you must first understand the unique way water is removed. It is not evaporated with heat, but sublimated under a vacuum.

The Role of Sublimation

First, the product is frozen solid, locking its cellular structure in place. Then, it is placed in a strong vacuum.

This combination of low temperature and low pressure allows the frozen water crystals to turn directly into a gas, completely bypassing the liquid phase. This gentle process is called sublimation.

Preserving the Original Structure

Because the water never melts and flows out, it doesn't cause the shrinkage, toughening, or collapse of the product's structure. The delicate cell walls remain intact and undamaged.

This is the primary difference between freeze-drying and conventional dehydration, which uses heat to evaporate water, inevitably altering the product's physical form.

Creating a Porous "Sponge"

When the ice crystals sublimate, they leave behind microscopic pores and channels exactly where they used to be.

The final product is essentially a perfectly preserved, porous matrix of the original item. This "sponge" is now ready to rapidly and completely absorb water when it's time for rehydration.

What This Means for Product Quality

The preservation of this internal structure has a direct and profound impact on the final rehydrated product, making it far superior to conventionally dried goods.

Rapid and Complete Water Absorption

The network of pores allows water to travel quickly and deeply into the product. Rehydration is often nearly instantaneous, taking minutes instead of hours.

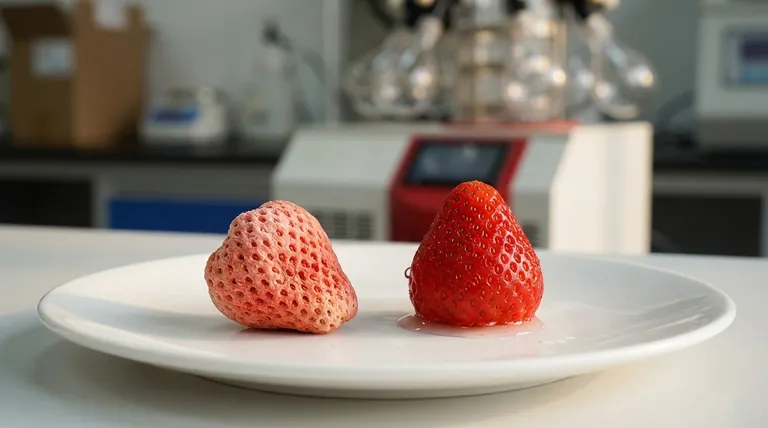

Restoring Texture and Shape

Since the structural foundation was never compromised, the rehydrated product closely resembles its fresh counterpart. A freeze-dried strawberry rehydrates into a plump, tender strawberry, not a tough, shriveled version.

Minimal Loss of Flavor and Quality

The low-temperature process ensures that volatile aromatic compounds and heat-sensitive nutrients are not destroyed. This means the final product retains the taste and nutritional value of the original.

Understanding the Trade-offs

While the rehydration quality is unmatched, the method is not without its considerations. Understanding these trade-offs is key to appreciating its value.

Process Time and Cost

Freeze-drying is a slow, energy-intensive process that requires specialized equipment. This makes freeze-dried products significantly more expensive than those produced by other methods.

Product Fragility

The highly porous structure that allows for excellent rehydration also makes the dry product very light and brittle. It requires careful handling and robust packaging to prevent it from being crushed into powder.

Making the Right Choice for Your Goal

The decision to use or purchase freeze-dried products depends entirely on your priority.

- If your primary focus is long-term storage and emergency preparedness: The near-perfect preservation and reliable rehydration make it the gold standard for food you can count on decades from now.

- If your primary focus is culinary quality and flavor: Freeze-drying is the best way to preserve delicate ingredients like herbs, fruits, or high-end meats for use in gourmet applications.

- If your primary focus is lightweight convenience for activities like backpacking: The combination of minimal weight and the ability to be restored into a high-quality meal is unbeatable.

Ultimately, freeze-drying's rehydration capability offers a unique bridge between the convenience of a preserved good and the quality of a fresh one.

Summary Table:

| Key Feature | Benefit of Freeze-Drying |

|---|---|

| Rehydration Speed | Near-instantaneous water absorption |

| Texture & Shape | Restores to original form, unlike conventional drying |

| Flavor & Nutrition | Preserves heat-sensitive compounds and nutrients |

| Structural Integrity | Porous, sponge-like matrix allows complete rehydration |

Achieve Unmatched Product Quality with KINTEK Lab Equipment

Whether you are developing new food products, preserving delicate pharmaceuticals, or advancing materials science, the integrity of your freeze-dried results is paramount. KINTEK specializes in precision lab equipment, including freeze dryers designed to deliver the superior structural preservation and rapid rehydration capabilities detailed in this article.

Our solutions are trusted by laboratories focused on quality, reliability, and innovation. Let us help you optimize your freeze-drying process for exceptional outcomes.

Contact our experts today to discuss your specific application needs and discover the KINTEK advantage.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure