At its core, frequency is the primary control for heating depth in an induction process. A higher frequency concentrates the heating effect near the surface of a workpiece, while a lower frequency allows the heat to penetrate deeper into the material. This single principle dictates which frequency is appropriate for any given application.

The choice between high and medium frequency is not about which is "better," but about answering a fundamental question: Do you need to heat the surface or the entire body of the part? Your answer directly determines the correct frequency range for your process.

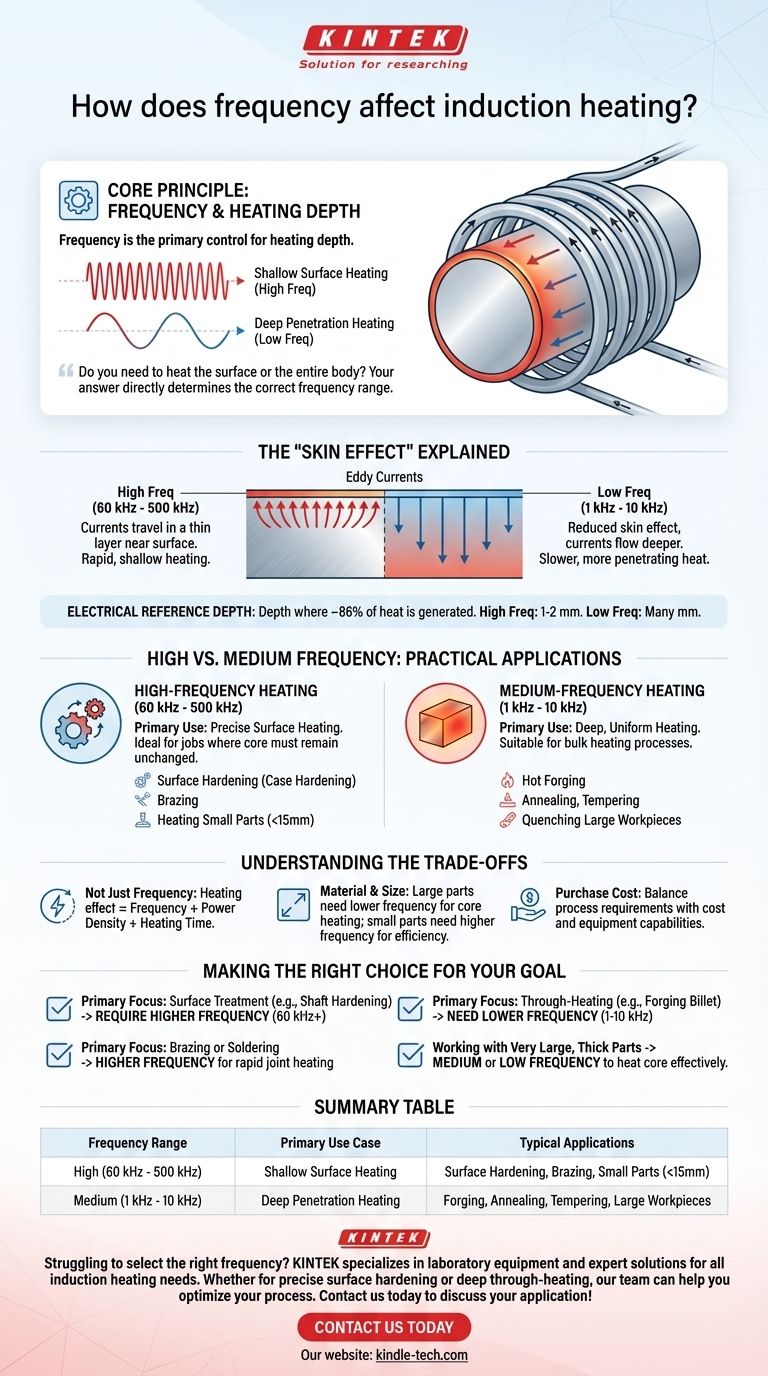

The Core Principle: Frequency and Heating Depth

To understand why frequency has this effect, we need to look at how induction works and a phenomenon known as the "skin effect."

How Induction Heating Works

Induction heating uses a coil to generate a powerful, rapidly alternating magnetic field. When a conductive workpiece (like a steel part) is placed inside this field, it induces electrical currents, known as eddy currents, within the part itself. The material's resistance to the flow of these currents is what generates precise, localized heat.

The "Skin Effect"

The frequency of the alternating current in the coil dictates where these eddy currents flow within the workpiece. This is due to the skin effect, a physical principle where alternating currents tend to flow on the outer layer, or "skin," of a conductor.

Higher frequencies cause the eddy currents to travel in a very thin layer near the surface, resulting in rapid, shallow heating.

Lower frequencies reduce the skin effect, allowing the eddy currents to flow deeper into the workpiece, resulting in slower, more penetrating heat.

Defining "Electrical Reference Depth"

This concept is often quantified as the electrical reference depth. It refers to the depth from the surface where approximately 86% of the heat is generated. A high-frequency process might have a reference depth of 1-2 mm, while a low-frequency process could have a depth of many millimeters.

High vs. Medium Frequency: Practical Applications

The choice of frequency is dictated entirely by the process requirements for the material and the desired outcome.

High-Frequency Heating (60 kHz - 500 kHz)

High-frequency induction is used for applications requiring precise surface heating. Because the heat is generated in a shallow layer, it is ideal for jobs where the core properties of the material must remain unchanged.

Common applications include surface hardening (case hardening), brazing, and the heating of very small parts (e.g., round bars under 15mm).

Medium-Frequency Heating (1 kHz - 10 kHz)

Medium-frequency induction is the choice for applications that demand deep, uniform heating through a large cross-section of the material. Its ability to penetrate deep into the part makes it suitable for bulk heating processes.

Common applications include hot forging, annealing, tempering, and the quenching of large workpieces where deep hardness is required.

Understanding the Trade-offs

While the heating depth is the primary driver, other factors influence the final decision.

It's Not Just About Frequency

The final heating effect is a result of frequency, power density, and heating time. A high-power, medium-frequency machine might achieve a similar surface heat as a lower-power, high-frequency machine in some scenarios, introducing other variables into the equation.

Material and Size Considerations

The size of the workpiece is critical. For very large parts, a lower frequency is essential to ensure the heat can reach the core before the surface becomes overheated. Conversely, trying to heat a very small part with a low frequency is often inefficient.

Purchase Cost and Equipment

The selection of equipment involves balancing process requirements with cost. Sometimes, a higher-power machine at one frequency can perform the same job as a lower-power machine at another. This requires a comprehensive analysis of the specific workpiece and production goals.

Making the Right Choice for Your Goal

Ultimately, your process goal dictates the correct frequency. Use these guidelines to make an informed decision.

- If your primary focus is surface treatment (like case hardening a shaft): You require a higher frequency (60 kHz+) to concentrate the heat precisely on the surface.

- If your primary focus is through-heating (like preparing a large billet for forging): You need a lower frequency (1-10 kHz) to ensure deep and uniform heat penetration.

- If your primary focus is brazing or soldering: A higher frequency is almost always used for its ability to rapidly heat the joint area without affecting the rest of the assembly.

- If you are working with very large, thick parts: A medium or low frequency is necessary to overcome the mass and heat the part's core effectively.

Matching the frequency to the desired heating outcome is the most critical step in designing an effective induction process.

Summary Table:

| Frequency Range | Primary Use Case | Typical Applications |

|---|---|---|

| High (60 kHz - 500 kHz) | Shallow Surface Heating | Surface Hardening, Brazing, Small Parts (<15mm) |

| Medium (1 kHz - 10 kHz) | Deep Penetration Heating | Forging, Annealing, Tempering, Large Workpieces |

Struggling to select the right frequency for your induction heating process? KINTEK specializes in laboratory equipment and consumables, providing expert solutions for all your induction heating needs. Whether you require precise surface hardening or deep through-heating for large parts, our team can help you optimize your process for maximum efficiency and quality. Contact us today to discuss your specific application and discover how KINTEK can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures