At its core, silicon carbide (SiC) heating elements are used for industrial applications demanding reliable, high-temperature heating from 600°C to over 1600°C (1100°F to 2900°F). They are critical components in processes like ceramic firing, float glass production, non-ferrous metal melting, sintering, and brazing, serving as the workhorse for various high-temperature furnaces.

The decision to use silicon carbide heating elements is not just about reaching a high temperature; it's about leveraging their unique ability to deliver stable, efficient, and long-lasting heat in environments where conventional metallic elements would quickly fail.

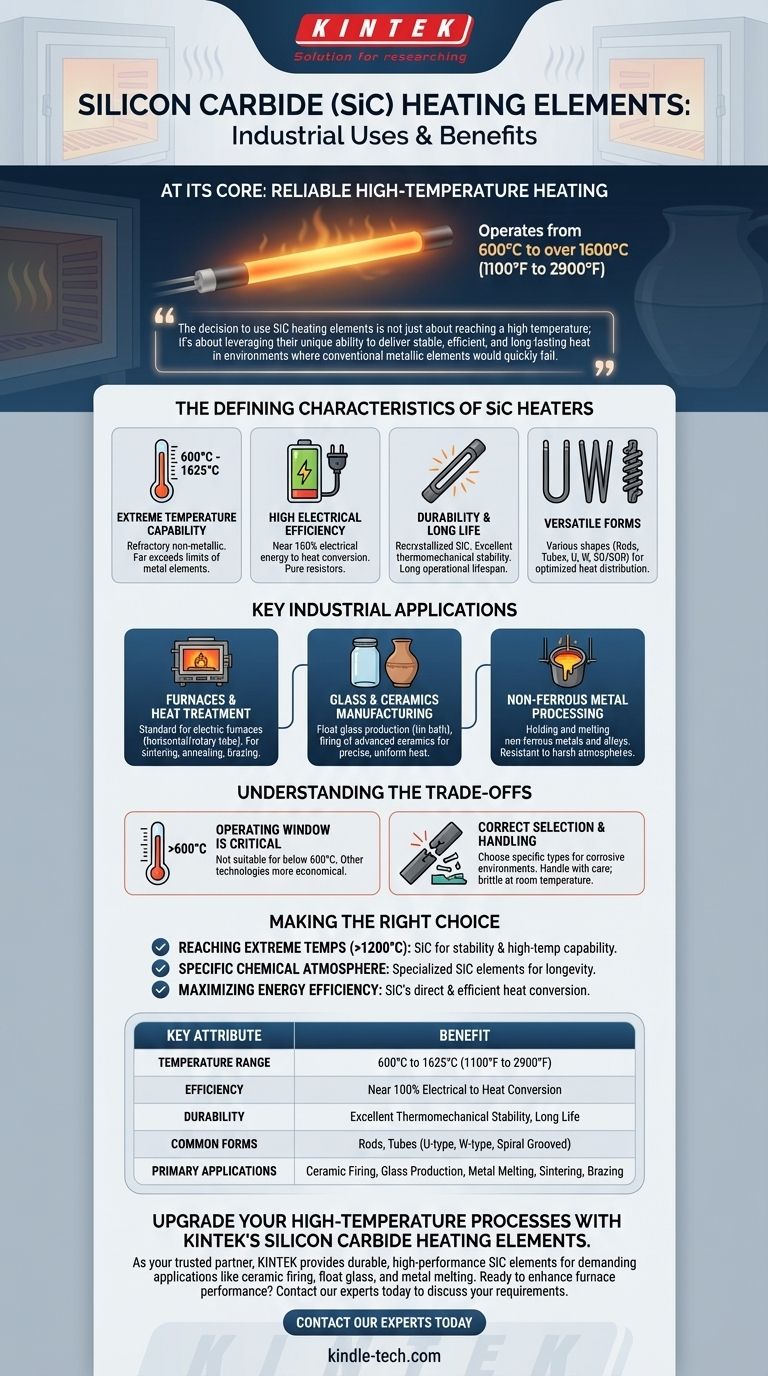

The Defining Characteristics of SiC Heaters

To understand why SiC elements are chosen, we must first look at their fundamental properties. They are not simply a hotter alternative to metallic elements but a different class of technology altogether.

Extreme Temperature Capability

Silicon carbide is a refractory, non-metallic material. This allows it to operate reliably in a temperature range of 600°C to 1625°C, far exceeding the limits of most metal heating elements.

High Electrical Efficiency

SiC elements offer superior electrical efficiency. They function as pure resistors, converting nearly 100% of the electrical energy supplied directly into usable heat.

Durability and Long Service Life

These elements are manufactured by recrystallizing high-quality green silicon carbide at extreme temperatures. The result is a rigid, durable component with outstanding thermomechanical stability and a long operational lifespan, especially when operated correctly.

Versatile Forms and Geometries

SiC heaters are produced in various shapes to suit different furnace designs and applications. Standard forms include rods and tubes, with common configurations like U-type, W-type, and spiral grooved rods (SG/SGR) allowing for optimized heat distribution and electrical connections.

Key Industrial Applications

The unique properties of SiC elements make them indispensable in several key industries where precise, high-temperature control is non-negotiable.

Furnaces and Heat Treatment

SiC elements are the standard for many electric furnaces, including horizontal tube furnaces and rotary tube furnaces. They are used for demanding heat treatment processes like sintering, annealing, and brazing materials that require high temperatures.

Glass and Ceramics Manufacturing

The production of float glass relies on SiC elements to maintain stable, high temperatures in the tin bath. Similarly, the firing of advanced ceramics requires the precise and uniform heat that SiC elements provide.

Non-Ferrous Metal Processing

In metallurgy, SiC elements are frequently used in furnaces for holding and melting non-ferrous metals and their alloys. Their resistance to the harsh furnace atmosphere makes them a reliable choice.

Understanding the Trade-offs

While powerful, SiC elements are a specialized tool. Understanding their operational boundaries is critical for success and longevity.

The Importance of the Operating Window

SiC elements are designed for high-temperature work. They are generally not suitable for applications operating below 600°C, where other heating technologies would be more effective and economical.

The Need for Correct Element Selection

SiC elements are available in numerous configurations, with some specifically designed to extend life in corrosive environments. Choosing the wrong type of element for a specific chemical atmosphere can significantly reduce its service life and performance.

Simplified Installation, Critical Handling

Their ceramic nature gives them excellent stability at high temperatures, simplifying furnace design. However, it also means they are brittle at room temperature and must be handled with care during installation and maintenance to prevent mechanical shock or fracture.

Making the Right Choice for Your Application

Selecting the correct heating element technology comes down to your primary operational goal.

- If your primary focus is reaching extreme temperatures (above 1200°C): SiC is a leading choice due to its stability and high-temperature capability, outperforming standard metallic elements.

- If your primary focus is operating in a specific chemical atmosphere: Select a specialized SiC element configuration engineered to maximize life in your particular process environment.

- If your primary focus is maximizing energy efficiency in a high-temp process: SiC's direct and efficient conversion of electricity to heat makes it an excellent option for reducing energy waste.

By understanding these core principles, you can confidently determine if silicon carbide is the right technology for your high-temperature application.

Summary Table:

| Key Attribute | Benefit |

|---|---|

| Temperature Range | 600°C to 1625°C (1100°F to 2900°F) |

| Efficiency | Near 100% electrical energy to heat conversion |

| Durability | Excellent thermomechanical stability and long service life |

| Common Forms | Rods, tubes (U-type, W-type, spiral grooved) |

| Primary Applications | Ceramic firing, glass production, metal melting, sintering, brazing |

Upgrade your high-temperature processes with KINTEK's silicon carbide heating elements.

As your trusted partner in laboratory equipment and consumables, KINTEK provides durable, high-performance SiC heating elements designed for demanding industrial applications. Whether you're firing advanced ceramics, producing float glass, or melting non-ferrous metals, our solutions deliver the precise, stable heat you need for superior results and energy efficiency.

Ready to enhance your furnace performance? Contact our experts today to discuss your specific requirements and discover the right SiC heating solution for your lab or production facility.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Double Plate Heating Press Mold for Lab

People Also Ask

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes