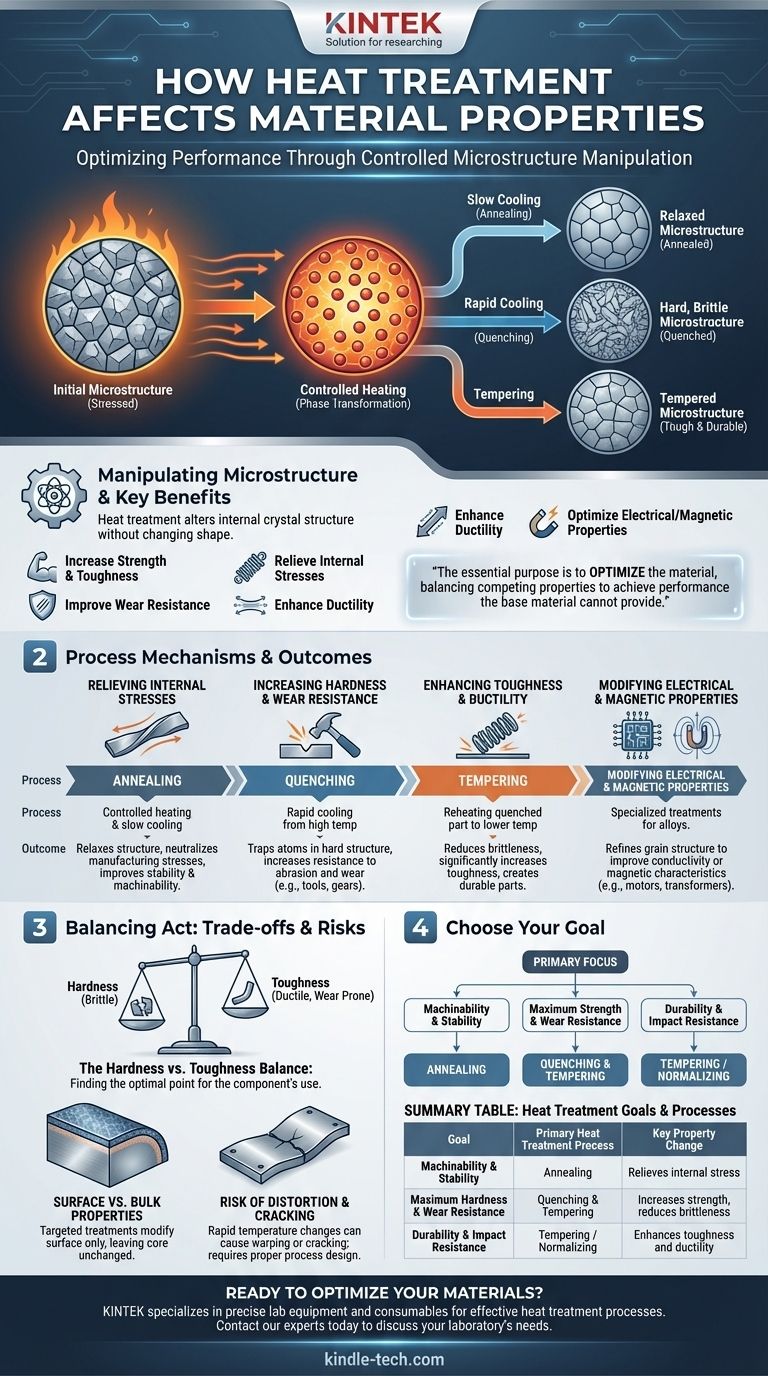

At its core, heat treatment is a controlled process of heating and cooling that fundamentally alters a material’s internal microstructure. This manipulation allows engineers to precisely change a material's physical and mechanical properties, tailoring its performance for a specific application without changing its shape. The primary benefits include increasing strength, improving toughness, enhancing wear resistance, and relieving internal stresses from manufacturing.

The essential purpose of heat treatment is not just to change a material, but to optimize it. It is a critical engineering tool for balancing competing properties—like hardness and ductility—to achieve a level of performance that the base material alone cannot provide.

The Core Principle: Manipulating Microstructure

Heat treatment works by modifying the internal crystal structure of a material, most commonly a metal like steel. By controlling the temperature, duration of heating, and the rate of cooling, you can dictate how the atoms arrange themselves, directly impacting the final properties of the component.

Relieving Internal Stresses

Manufacturing processes like welding, machining, or forming introduce significant stress into a material's structure. These residual stresses can cause warping or premature failure.

A controlled heating and slow cooling cycle, known as annealing, allows the material's internal structure to relax and realign, effectively neutralizing these stresses and making the part more stable and easier to work with.

Increasing Hardness and Wear Resistance

To make a material harder, it is heated to a high temperature and then cooled rapidly in a process called quenching. This rapid cooling traps the atoms in a very hard, brittle crystalline structure.

This increased hardness directly improves a component's ability to resist abrasion, indentation, and wear, which is critical for tools, gears, and bearings.

Enhancing Toughness and Ductility

Extreme hardness often comes with a major drawback: brittleness. A quenched part might be very hard but could shatter under a sharp impact.

To counteract this, a secondary process called tempering is often used. The part is reheated to a lower temperature, which slightly reduces the hardness but significantly increases its toughness (the ability to absorb energy and deform without fracturing). This creates a more durable and reliable part.

Modifying Electrical and Magnetic Properties

Beyond mechanical changes, heat treatment can also refine a material's grain structure to enhance specific physical properties.

For certain alloys, this can improve electrical conductivity or optimize magnetic characteristics, which is essential for components in electric motors and transformers.

Understanding the Trade-offs

Heat treatment is a balancing act. Improving one property often comes at the expense of another, and the process itself introduces risks that must be managed.

The Hardness vs. Toughness Balance

This is the most fundamental trade-off in heat treatment. A material that is extremely hard is often brittle. Conversely, a very tough and ductile material is typically softer and less resistant to wear.

The goal of a specific heat treatment process is to find the optimal point on this spectrum for the component's intended use.

Surface vs. Bulk Properties

Some applications require a part to have a very hard, wear-resistant surface while maintaining a softer, tougher core to absorb impact.

Treatments like plasma nitriding or case hardening modify only the surface chemistry and structure, leaving the bulk properties of the material unchanged. This creates a composite material with the best of both worlds, but it is a more complex and targeted process than bulk heat treatment.

Risk of Distortion and Cracking

The rapid temperature changes involved in processes like quenching create immense internal stress. If not carefully controlled, this can cause the part to warp, distort, or even crack during the treatment.

Proper process design, material selection, and part geometry are critical to mitigating these risks.

Making the Right Choice for Your Goal

The specific heat treatment process you choose should be driven directly by the primary performance requirement of the component.

- If your primary focus is machinability and post-weld stability: Your goal is to relieve stress, so a process like annealing is the correct choice.

- If your primary focus is maximum strength and wear resistance: You need to create a hard structure through quenching, followed by tempering to reduce brittleness.

- If your primary focus is durability and impact resistance: Your goal is to maximize toughness, which often involves tempering or normalizing to create a resilient internal structure.

Ultimately, viewing heat treatment as a strategic tool allows you to unlock the full potential of your chosen material.

Summary Table:

| Goal | Primary Heat Treatment Process | Key Property Change |

|---|---|---|

| Machinability & Stability | Annealing | Relieves internal stress |

| Maximum Hardness & Wear Resistance | Quenching & Tempering | Increases strength, reduces brittleness |

| Durability & Impact Resistance | Tempering / Normalizing | Enhances toughness and ductility |

Ready to optimize your materials?

KINTEK specializes in the precise lab equipment and consumables needed for effective heat treatment processes. Whether you're developing new alloys or ensuring quality control, our solutions help you achieve the perfect balance of material properties.

Contact our experts today to discuss how we can support your laboratory's specific needs.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- Can nitrogen be used for brazing? Key Conditions and Applications Explained

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab