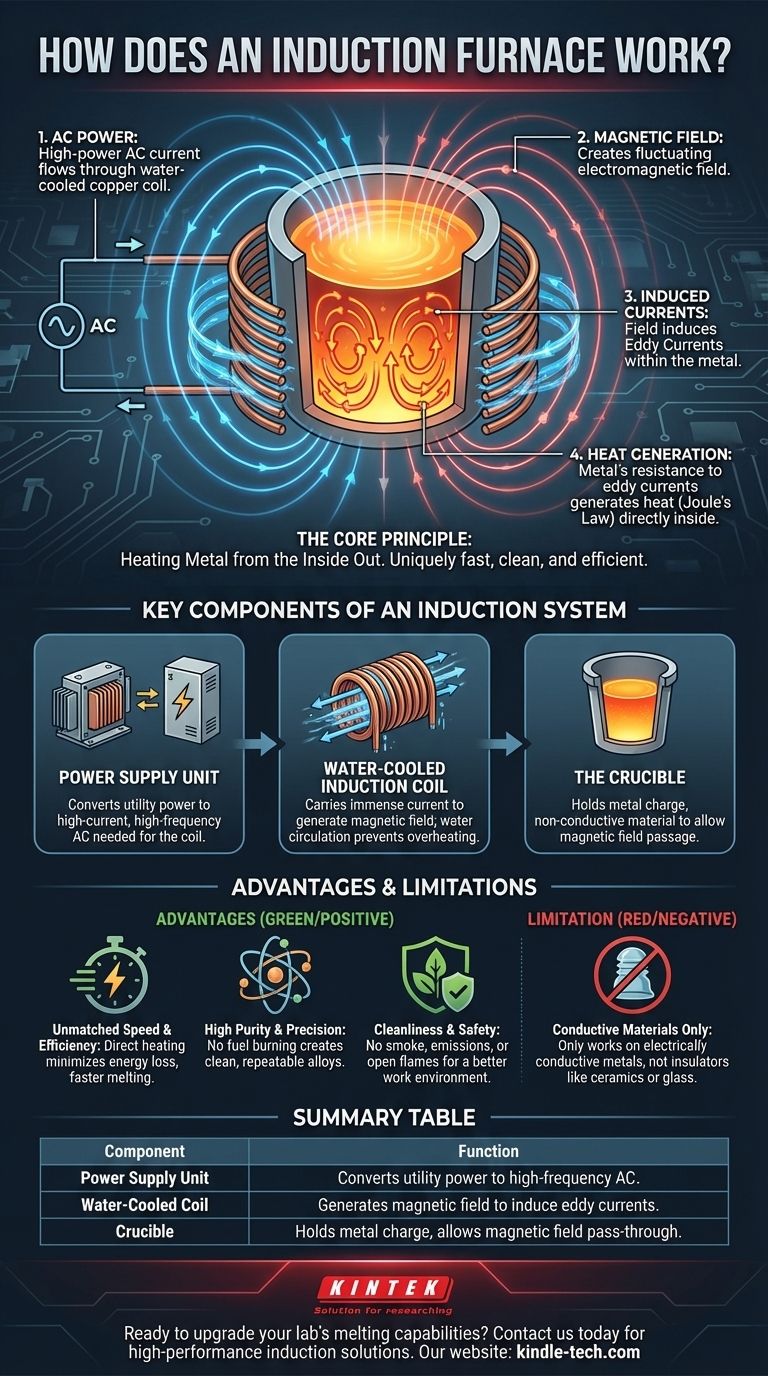

At its core, an induction furnace works by using a powerful, changing magnetic field to generate heat directly within the metal itself. An alternating electric current (AC) is passed through a copper coil, which creates an electromagnetic field. This field induces smaller electric currents, known as eddy currents, inside the conductive metal charge, and the metal's natural resistance to these currents generates intense heat that causes it to melt.

Instead of using external flames or heating elements that heat a container from the outside, an induction furnace turns the metal itself into the source of the heat. This "inside-out" heating principle is what makes the process uniquely fast, clean, and efficient.

The Core Principle: Heating Metal from the Inside Out

The technology behind an induction furnace is based on the principles of electromagnetism discovered by Michael Faraday. It is a non-contact heating method that converts electrical energy into heat with remarkable precision.

The Copper Coil and Alternating Current

The process begins with a high-power alternating current flowing through a hollow, water-cooled copper coil. This coil is shaped to surround the crucible that holds the metal to be melted.

Creating the Electromagnetic Field

As the AC current flows and rapidly reverses direction, it generates a powerful and fluctuating magnetic field in the space within and around the coil.

Inducing Eddy Currents

This magnetic field passes directly through the electrically conductive metal (the "charge") placed inside the crucible. The field induces small, circular electric currents within the metal, known as eddy currents.

Generating Heat Through Resistance

The metal has a natural electrical resistance. As the induced eddy currents swirl through it, this resistance creates friction and generates immense heat, a principle described by Joule's law. This heat rapidly raises the metal's temperature to its melting point and beyond.

Key Components of an Induction System

An induction furnace is more than just a coil. It is a carefully integrated system designed for safety, efficiency, and control.

The Power Supply Unit

This is the heart of the system. It consists of transformers and an inverter that convert standard utility power into the high-current, high-frequency electricity needed to drive the induction coil effectively.

The Water-Cooled Induction Coil

The copper coil carries an enormous amount of electric current, which generates its own heat. It is built with hollow tubing so water can be constantly circulated through it, preventing the coil itself from overheating and melting.

The Crucible

The crucible is the refractory-lined vessel that sits inside the coil and contains the metal charge. It must be made of a material that can withstand extreme temperatures but does not conduct electricity, so the magnetic field can pass through it to reach the metal.

Understanding the Trade-offs and Advantages

No technology is perfect for every application. Understanding where an induction furnace excels is key to appreciating its value.

Advantage: Unmatched Speed and Efficiency

Because the heat is generated directly within the metal, very little energy is wasted heating the furnace walls or the surrounding air. This results in much faster melting times and higher overall energy efficiency compared to combustion-based furnaces.

Advantage: High Purity and Precision

There is no burning fuel, so no contaminants like sulfur or carbon from the combustion process are introduced into the melt. This allows for the creation of extremely pure metals and alloys of an exact, repeatable composition.

Advantage: Cleanliness and Safety

Induction furnaces produce no smoke, waste heat, or noxious emissions. This creates a cleaner, cooler, and safer working environment compared to traditional foundries.

Limitation: Conductive Materials Only

The primary limitation of induction heating is that it only works on electrically conductive materials. It cannot be used to directly heat insulators like ceramics or glass.

Making the Right Choice for Your Goal

The decision to use an induction furnace is driven by the specific requirements of the metallurgical process.

- If your primary focus is rapid melting and high purity: Induction is the superior choice for creating precise metal alloys without the risk of contamination from burning fuel.

- If your primary focus is energy efficiency and a clean work environment: The direct heating mechanism of an induction furnace minimizes energy loss and eliminates pollutants, making it ideal for modern industrial settings.

- If you are processing non-conductive materials: You must use an alternative, such as a resistance-heated furnace, as the principle of induction will not apply.

Ultimately, the induction furnace provides a clean, fast, and highly controlled method for melting metals that is fundamentally more advanced than traditional heating technologies.

Summary Table:

| Component | Function |

|---|---|

| Power Supply Unit | Converts utility power to high-frequency AC for the coil. |

| Water-Cooled Coil | Generates a magnetic field to induce eddy currents in the metal. |

| Crucible | Holds the metal charge while allowing the magnetic field to pass through. |

Ready to upgrade your lab's melting capabilities? KINTEK specializes in high-performance induction furnaces and lab equipment, delivering the speed, purity, and energy efficiency your laboratory demands. Contact us today to find the perfect solution for your metal melting needs!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Why is using a vacuum hot press for diamond composites preferred? Achieve Maximum Thermal Conductivity

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- Why is a vacuum environment necessary for sintering ZrB2-SiC composites? Master High-Performance Ceramic Fabrication

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- What are the advantages of using vacuum hot pressing for CoCrCuFeNi? Superior Strength via Microstructural Control