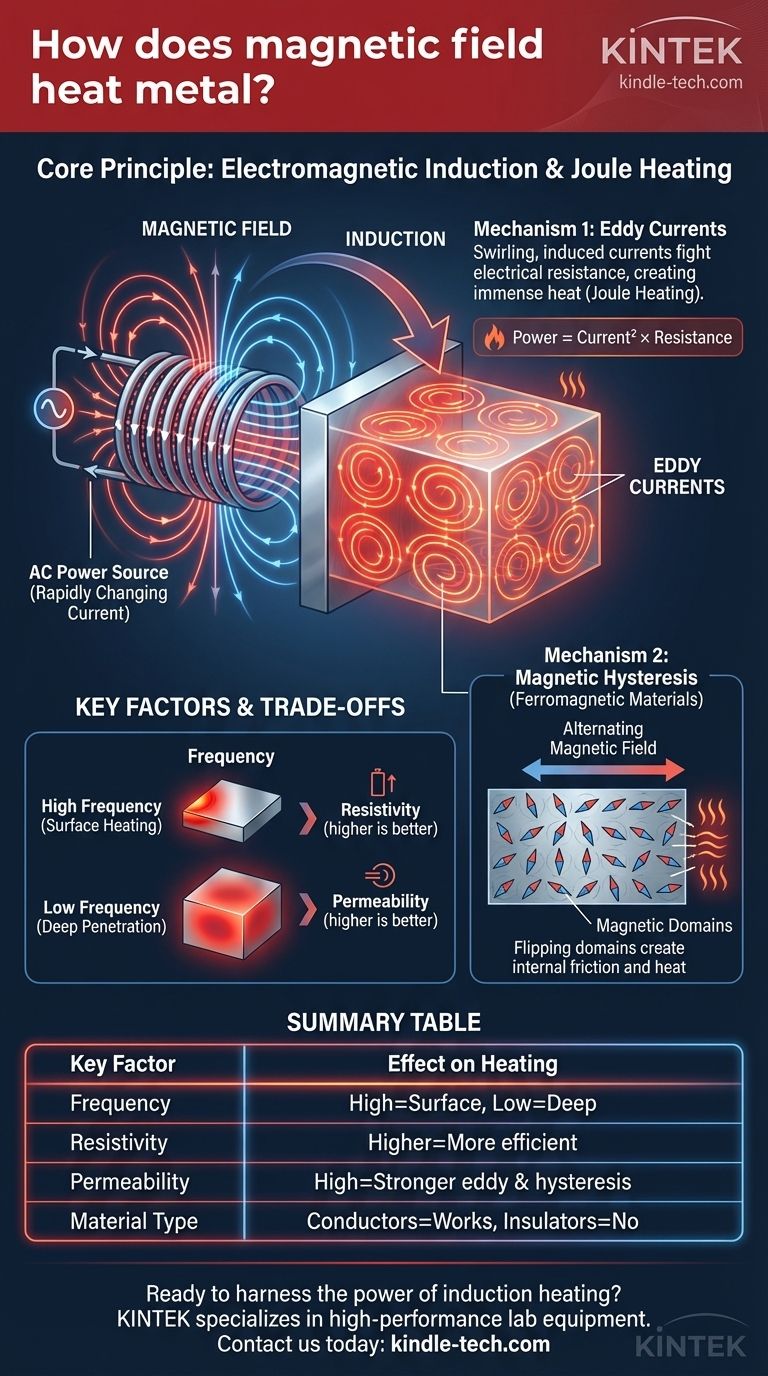

In short, a magnetic field heats metal by inducing powerful electrical currents inside it. This process requires a magnetic field that is rapidly changing or alternating, not a static one. The metal’s natural electrical resistance fights against these induced currents, generating immense heat through a process identical to how a resistor in an electronic circuit gets hot.

The core principle is electromagnetic induction. An alternating magnetic field generates circular electric currents—called eddy currents—within the metal. The metal's inherent resistance converts this electrical energy into heat, a phenomenon known as Joule heating.

The Core Principle: Faraday's Law of Induction

A stationary magnet next to a piece of metal will do nothing. The magic happens when the magnetic field changes over time, a fundamental concept described by Faraday's Law of Induction.

A Changing Field Creates a Current

Faraday's Law states that a changing magnetic field creates an electric field. In a conductive material like metal, which is full of free-flowing electrons, this induced electric field forces the electrons to move, creating an electrical current.

To achieve this in practice, we use an electromagnet powered by an alternating current (AC). By rapidly switching the current's direction—often thousands or millions of times per second—we generate a powerful and constantly changing magnetic field.

Mechanism 1: Eddy Currents (The Primary Effect)

The primary mechanism for this heating is the generation of eddy currents. These are closed loops of induced current that swirl within the metal, perpendicular to the direction of the magnetic field.

You can visualize them like eddies or whirlpools forming in a river as water flows past a large rock. The changing magnetic field is the "flow," and the eddy currents are the "whirlpools" of electricity it creates within the metal.

The Power of Resistance (Joule Heating)

These powerful currents don't flow for free. The metal has an inherent electrical resistance. As the eddy currents circulate against this resistance, energy is lost in the form of heat.

This is called Joule heating, described by the formula Power = Current² × Resistance. Because the induced currents can be very large, they generate a significant amount of heat very quickly. This is the main heating effect for non-magnetic metals like aluminum, copper, and brass.

Mechanism 2: Magnetic Hysteresis (For Iron and Steel)

For ferromagnetic materials like iron, nickel, and many types of steel, a second heating mechanism contributes to the effect: magnetic hysteresis.

Flipping Magnetic Domains

Ferromagnetic materials are composed of microscopic regions called magnetic domains, which act like tiny permanent magnets. When no external field is present, these domains are randomly oriented.

When an external alternating magnetic field is applied, it forces these domains to rapidly align and re-align themselves with the field's changing direction.

Heating Through Internal Friction

This constant, high-speed flipping of magnetic domains is not perfectly efficient. It creates a type of internal friction within the material's crystal structure, which generates heat.

A common analogy is bending a paperclip back and forth. The metal at the bend gets hot due to the internal stress and friction. Hysteresis heating is a similar process on a microscopic scale. This effect is most significant at lower frequencies and diminishes as the metal heats up past its Curie temperature, the point where it loses its magnetic properties.

Understanding the Key Factors

The effectiveness of induction heating depends on several factors, creating important trade-offs in its application.

The Role of Frequency

The frequency of the alternating current is critical. Higher frequencies generate eddy currents that are concentrated near the surface of the metal. This phenomenon, known as the skin effect, is ideal for applications like surface hardening of steel parts.

Conversely, lower frequencies penetrate deeper into the metal, allowing for uniform, through-heating of larger objects. This is used for processes like forging or melting large billets of metal.

Material Properties Matter

A material's electrical resistivity and magnetic permeability are key. Materials with higher resistivity (like steel) heat up more efficiently from eddy currents than materials with very low resistivity (like copper).

High magnetic permeability (found in iron) concentrates the magnetic field, leading to stronger eddy currents and the added benefit of hysteresis heating, making ferromagnetic materials heat exceptionally well.

Why Some Materials Don't Heat

Induction does not work on non-conductive materials like glass, plastic, or ceramic because they lack the free electrons needed to form eddy currents. This is why the glass surface of an induction cooktop remains cool while the iron pot on top gets hot.

Applying This to Your Goal

The right approach depends entirely on what you want to achieve.

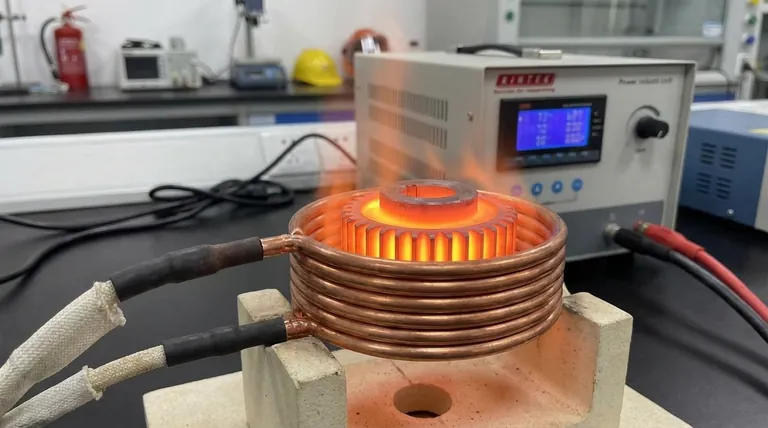

- If your primary focus is surface hardening a steel gear: Use a very high frequency to concentrate the heat exclusively on the surface layer, keeping the core strong and ductile.

- If your primary focus is melting a block of aluminum: Use a much lower frequency to ensure the magnetic field penetrates deep into the material for uniform, thorough melting.

- If your primary focus is cooking with an induction stove: The system uses a frequency optimized to heat ferromagnetic cookware (iron, steel) using both eddy currents and hysteresis, while remaining safe and cool to the touch.

Ultimately, induction heating is a powerful demonstration of how a fundamental law of physics can be harnessed for precise and efficient thermal control.

Summary Table:

| Key Factor | Effect on Heating |

|---|---|

| Frequency | High frequency = surface heating; Low frequency = deep heating |

| Material Resistivity | Higher resistivity (e.g., steel) = more efficient heating |

| Magnetic Permeability | High permeability (e.g., iron) = stronger eddy currents & hysteresis heating |

| Material Type | Works on conductors (metals); Not on insulators (plastic, glass) |

Ready to harness the power of induction heating in your lab?

KINTEK specializes in high-performance lab equipment, including induction heating systems designed for precise thermal control in research and industrial applications. Whether you need surface hardening, melting, or specialized heating, our solutions deliver efficiency, safety, and repeatability.

Contact KINTEK today to discuss your specific needs and discover how our expertise in lab equipment can enhance your processes and results.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What are the uses of induction furnace? Achieve Clean, High-Purity Metal Melting

- What role does a vacuum induction furnace play in melting 12% Chromium steel? Ensuring Purity and Alloy Integrity

- What is the function of a Vacuum Induction Melting (VIM) furnace in FeCrAl steel prep? Ensure Ultimate Alloy Purity

- Why is a Vacuum Induction Melting Furnace required for Fe–10Cr–4Al? Achieve High Purity & Precise Alloy Composition

- How is iron produced in an induction furnace? Harnessing Clean, Efficient Melting Technology

- How many times can metal be melted down and used again? The Key to Infinite Recyclability

- What is the primary function of a vacuum induction melting furnace in Ni-Mo-Cr-Fe master alloy prep? Ensure High Purity

- What is the function of an induction melting furnace in FeCrAl alloy preparation? Ensure Precision and Purity