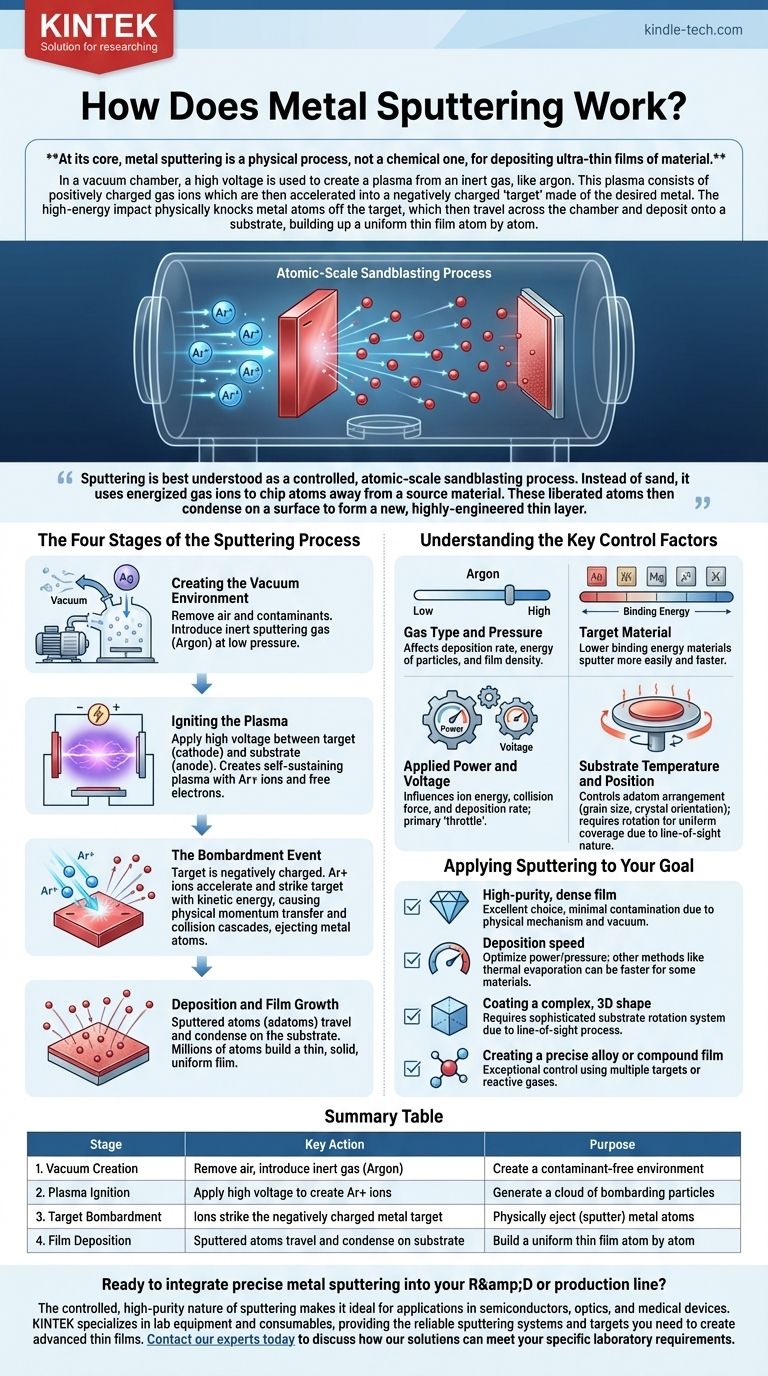

At its core, metal sputtering is a physical process, not a chemical one, for depositing ultra-thin films of material. In a vacuum chamber, a high voltage is used to create a plasma from an inert gas, like argon. This plasma consists of positively charged gas ions which are then accelerated into a negatively charged "target" made of the desired metal. The high-energy impact physically knocks metal atoms off the target, which then travel across the chamber and deposit onto a substrate, building up a uniform thin film atom by atom.

Sputtering is best understood as a controlled, atomic-scale sandblasting process. Instead of sand, it uses energized gas ions to chip atoms away from a source material. These liberated atoms then condense on a surface to form a new, highly-engineered thin layer.

The Four Stages of the Sputtering Process

To truly understand how sputtering works, it's best to break it down into a sequence of four distinct stages that occur inside the vacuum chamber.

Stage 1: Creating the Vacuum Environment

The entire process must happen in a controlled environment. A vacuum chamber is pumped down to remove air and other contaminants that could interfere with the process or become embedded in the film.

Once a high vacuum is achieved, a small, precisely controlled amount of an inert sputtering gas—most commonly Argon—is introduced into the chamber.

Stage 2: Igniting the Plasma

A high DC or RF voltage is applied between two electrodes: the target (the source material, which acts as the cathode) and the substrate (the object to be coated, which is on or near the anode).

This powerful electric field strips electrons from the Argon atoms. These free electrons collide with other Argon atoms, knocking more electrons loose in a chain reaction. This process creates a self-sustaining cloud of positively charged Argon ions (Ar+) and free electrons, which is known as a plasma.

Stage 3: The Bombardment Event

The target is given a strong negative charge, making it intensely attractive to the positively charged Argon ions in the plasma.

These ions accelerate rapidly towards the target, striking its surface with significant kinetic energy. This is a purely physical momentum transfer. The ion's impact sets off a "collision cascade" within the atomic structure of the target material, much like a cue ball breaking a rack of billiard balls.

When these collision cascades reach the surface, atoms of the target material are ejected or "sputtered" off into the vacuum chamber.

Stage 4: Deposition and Film Growth

The sputtered atoms from the target travel through the vacuum chamber until they strike the substrate.

Upon arrival, these atoms—sometimes called adatoms—condense on the cooler surface of the substrate. Over time, millions of these arriving atoms build upon each other to form a thin, solid, and highly uniform film with specific, engineered properties.

Understanding the Key Control Factors

The true power of sputtering lies in its precision. The final film's characteristics are not accidental; they are the direct result of carefully controlling several key variables in the process.

Gas Type and Pressure

The pressure of the sputtering gas inside the chamber affects the rate of deposition and the energy of the sputtered particles. Higher pressure can lead to more collisions and a less direct path for the sputtered atoms, which can alter the final film's density.

Target Material

The binding energy of the atoms in the target material is a critical factor. Materials with lower binding energy will sputter more easily and at a higher rate than materials with very strong atomic bonds.

Applied Power and Voltage

The amount of power applied to the target directly influences the energy of the bombarding ions. Higher power results in more forceful collisions, a higher sputtering rate, and faster film growth. This is the primary "throttle" for the process.

Substrate Temperature and Position

The temperature of the substrate affects how the arriving adatoms arrange themselves on the surface. Controlling temperature can influence critical properties like grain size and crystal orientation. Since sputtering is a line-of-sight process, the position and rotation of the substrate are crucial for achieving uniform coverage on complex shapes.

Applying Sputtering to Your Goal

Understanding the mechanics allows you to determine if sputtering is the right choice for your specific application.

- If your primary focus is a high-purity, dense film: Sputtering is an excellent choice, as the physical removal mechanism and vacuum environment minimize contamination.

- If your primary focus is deposition speed: You must optimize power and gas pressure, but be aware that other methods like thermal evaporation can sometimes be faster for certain materials.

- If your primary focus is coating a complex, 3D shape: Sputtering's line-of-sight nature means achieving uniform coverage will require a sophisticated substrate rotation system.

- If your primary focus is creating a precise alloy or compound film: Sputtering offers exceptional control, allowing for the use of multiple targets or the introduction of reactive gases (e.g., nitrogen to form nitrides) to create specific stoichiometries.

By controlling these fundamental physical principles, you can manipulate the sputtering process to build materials with exacting specifications, literally one layer of atoms at a time.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Vacuum Creation | Remove air, introduce inert gas (Argon) | Create a contaminant-free environment |

| 2. Plasma Ignition | Apply high voltage to create Ar+ ions | Generate a cloud of bombarding particles |

| 3. Target Bombardment | Ions strike the negatively charged metal target | Physically eject (sputter) metal atoms |

| 4. Film Deposition | Sputtered atoms travel and condense on substrate | Build a uniform thin film atom by atom |

Ready to integrate precise metal sputtering into your R&D or production line? The controlled, high-purity nature of sputtering makes it ideal for applications in semiconductors, optics, and medical devices. KINTEK specializes in lab equipment and consumables, providing the reliable sputtering systems and targets you need to create advanced thin films. Contact our experts today to discuss how our solutions can meet your specific laboratory requirements.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the impurities in pyrolysis oil? Unlocking the Complex Chemistry of Bio-Crude

- What is an indirect arc furnace? Master Precise, Clean Metal Melting

- How thick is gold sputter coating? Optimize Your SEM Sample Preparation for Clear Images

- What is sintering in manufacturing process? A Guide to Creating Dense, High-Performance Parts

- What is a metal test called? A Guide to Heavy Metals Panels and Toxic Exposure Testing

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is the sputtering process for deposition? A Guide to Precision Thin Film Coating

- How does catalytic pyrolysis work? Unlock Higher Yields of Valuable Fuels and Chemicals