At their core, oil-free diaphragm vacuum pumps and conventional oil-sealed pumps operate on the same principle of creating a pressure differential. The fundamental difference lies in their mechanical construction and, crucially, the absence of oil. Diaphragm pumps use a flexible, reciprocating membrane to create a vacuum, while many conventional pumps, like rotary vane pumps, rely on oil to seal gaps, lubricate parts, and achieve deeper vacuum levels.

The choice between an oil-free diaphragm pump and a conventional oil-sealed pump is not about which is "better" overall, but which is explicitly right for your application. Diaphragm pumps prioritize a clean, low-maintenance vacuum, while oil-sealed pumps prioritize achieving the deepest possible vacuum.

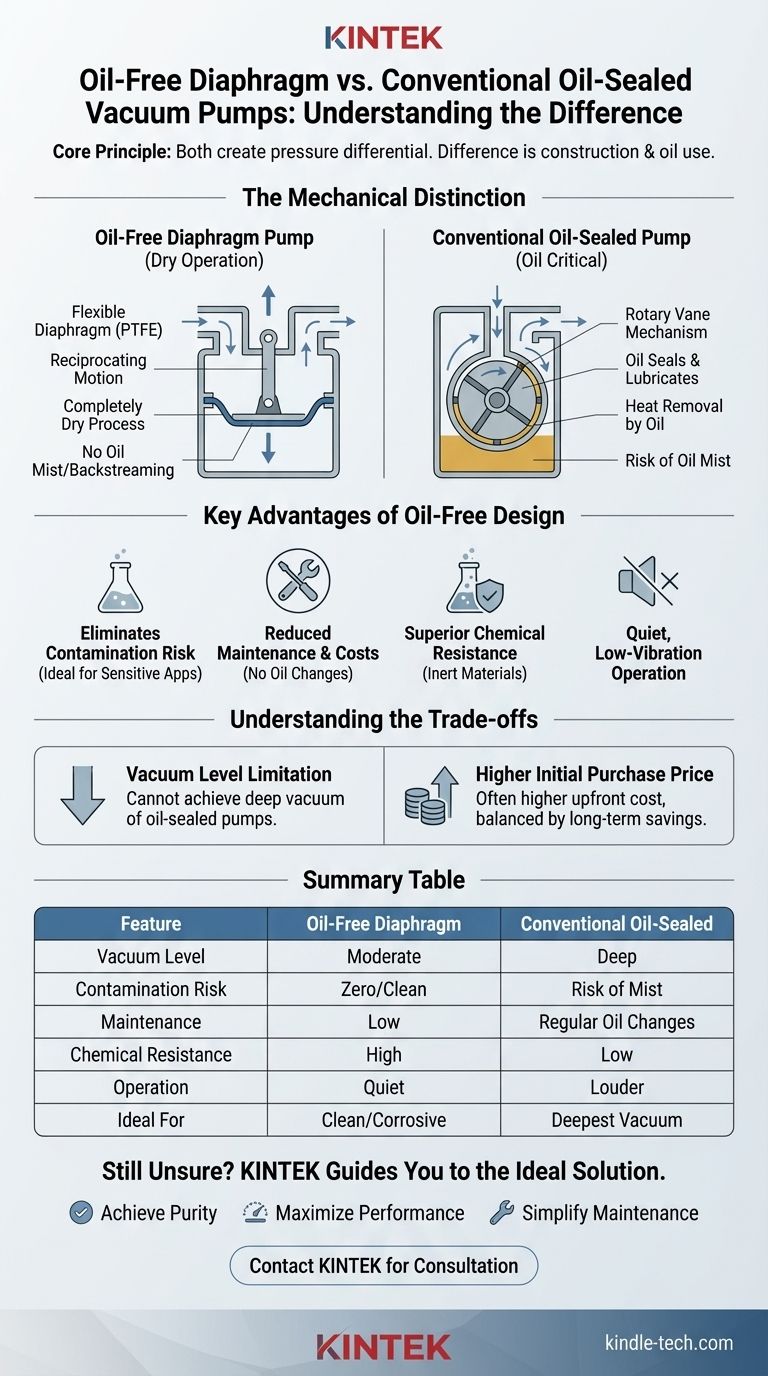

The Mechanical Distinction: Diaphragm vs. Oil-Sealed

To understand the practical differences, we must first look at how each pump generates a vacuum. The internal mechanism dictates every other characteristic.

How an Oil-Free Diaphragm Pump Works

An oil-free diaphragm pump is a type of positive displacement pump. It uses a flexible diaphragm, typically made of a resilient material like PTFE, which is moved up and down by a connecting rod.

This motion alternately increases and decreases the volume of a sealed chamber. As the volume increases, pressure drops, drawing gas in from the system. As the volume decreases, the gas is compressed and expelled through an outlet valve. This entire process is completely dry.

How a Conventional Oil-Sealed Pump Works

The most common "conventional" pump is the oil-sealed rotary vane pump. Inside a cylindrical housing, an off-center rotor spins with several spring-loaded vanes.

As the rotor turns, these vanes slide in and out, trapping pockets of gas and compressing them toward the exhaust port. Oil is critical to this process; it fills the tiny gaps to create a seal, lubricates the moving parts, and helps remove heat.

The Key Advantages of an Oil-Free Design

The elimination of oil is not just a minor feature; it is the defining characteristic that drives the primary benefits of a diaphragm pump.

Eliminating Contamination Risk

Because they use no oil, diaphragm pumps cannot produce an oil mist or have oil back-stream into your vacuum chamber or product. This is non-negotiable for sensitive applications where purity is paramount, such as cell culture or vacuum filtration.

Reduced Maintenance and Operating Costs

Oil-sealed pumps require regular oil checks and changes. This involves downtime, the cost of new oil, and the proper disposal of used, often contaminated, oil. Diaphragm pumps eliminate this entire maintenance cycle, reducing long-term operating costs.

Superior Chemical Resistance

Many diaphragm pumps are built with chemically inert materials (like PTFE) for all wetted parts. This makes them highly resistant to corrosion and ideal for pumping aggressive or acidic vapors that would degrade the oil in a conventional pump.

Quiet, Low-Vibration Operation

The reciprocating motion of a diaphragm pump is generally much quieter and produces less vibration than the high-speed spinning of a rotary vane pump. This makes them an excellent choice for laboratory workspaces where noise can be a disruptive factor.

Understanding the Trade-offs

No technology is without its limitations. The benefits of an oil-free design come with clear trade-offs in performance and cost that you must consider.

The Vacuum Level Limitation

This is the most significant trade-off. Oil-free diaphragm pumps cannot achieve the same deep vacuum (low absolute pressure) as an oil-sealed rotary vane pump. The oil provides a superior seal, allowing rotary vane pumps to reach much lower pressures.

Higher Initial Purchase Price

Diaphragm pumps, particularly chemically resistant models, often have a higher upfront purchase price compared to a standard rotary vane pump of similar pumping speed. This cost must be weighed against the long-term savings in maintenance and oil.

Making the Right Choice for Your Goal

The decision ultimately comes down to the specific demands of your task. A pump that is perfect for one application can be entirely wrong for another.

- If your primary focus is a clean, contamination-free vacuum: An oil-free diaphragm pump is the correct choice for its dry operation and low maintenance.

- If your primary focus is achieving the deepest possible vacuum: An oil-sealed rotary vane pump is the standard, but you must manage its maintenance and contamination risks.

- If your primary focus is handling corrosive chemicals or vapors: A chemically-resistant diaphragm pump is essential to ensure long-term reliability and prevent pump failure.

Understanding these core differences empowers you to select the right tool that aligns perfectly with your application's demands.

Summary Table:

| Feature | Oil-Free Diaphragm Pump | Conventional Oil-Sealed Pump |

|---|---|---|

| Vacuum Level | Moderate (Good for many lab tasks) | Deep (Ultimate pressure) |

| Contamination Risk | Zero oil contamination (Clean) | Risk of oil mist/backstreaming |

| Maintenance | Low (No oil changes) | Regular oil changes and disposal |

| Chemical Resistance | High (Chemically inert wetted parts) | Low (Oil degrades with vapors) |

| Operation | Quiet, low vibration | Louder, more vibration |

| Ideal For | Clean applications, sensitive samples, corrosive vapors | Applications requiring the deepest vacuum |

Still Unsure Which Vacuum Pump is Right for Your Lab?

Selecting the correct pump is critical for your results and workflow. KINTEK specializes in laboratory equipment and can help you make the perfect choice.

- Achieve Purity: Protect sensitive samples from oil contamination with our reliable diaphragm pumps.

- Maximize Performance: Get the deep vacuum you need with our range of robust oil-sealed pumps.

- Simplify Maintenance: Reduce downtime and operating costs with our low-maintenance solutions.

Let our experts guide you to the ideal vacuum solution for your specific application.

Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

People Also Ask

- What is the purpose of the slow cooling (annealing) process for Ni-TiO2? Ensure Material Stability and Performance

- How long does it take to heat treat steel? From Hours to Days, Depending on Your Goal

- How does a laboratory shaker evaluate chromium oxide nanoparticles on bacteria? Ensure Accurate Antimicrobial Testing

- What are the advantages and disadvantages of graphite? Mastering High-Temperature Performance vs. Contamination Risk

- What are the alternatives to plastic waste management? A Guide to Circular Solutions

- What is pyrolysis in renewable energy? Converting Biomass and Methane into Clean Fuels

- What does sintering depend on? Mastering Temperature, Pressure, Time & Material for Optimal Results

- What are the different types of reactors in pyrolysis? Match Your Reactor to Your Desired Product