Proper maintenance of an oil-free diaphragm vacuum pump is fundamentally about proactive care rather than reactive repair. The core activities involve ensuring the pump operates in a clean and stable environment, regularly inspecting connections for leaks, and periodically replacing the key wear components—the diaphragms and valves—according to the manufacturer's recommended service intervals.

Unlike oil-sealed pumps, maintaining an oil-free diaphragm pump is not about fluid changes but about proactive preservation. Your focus should be on protecting the key wear components—the diaphragms and valves—and ensuring the pump operates in a stable, clean, and cool environment to maximize its service life.

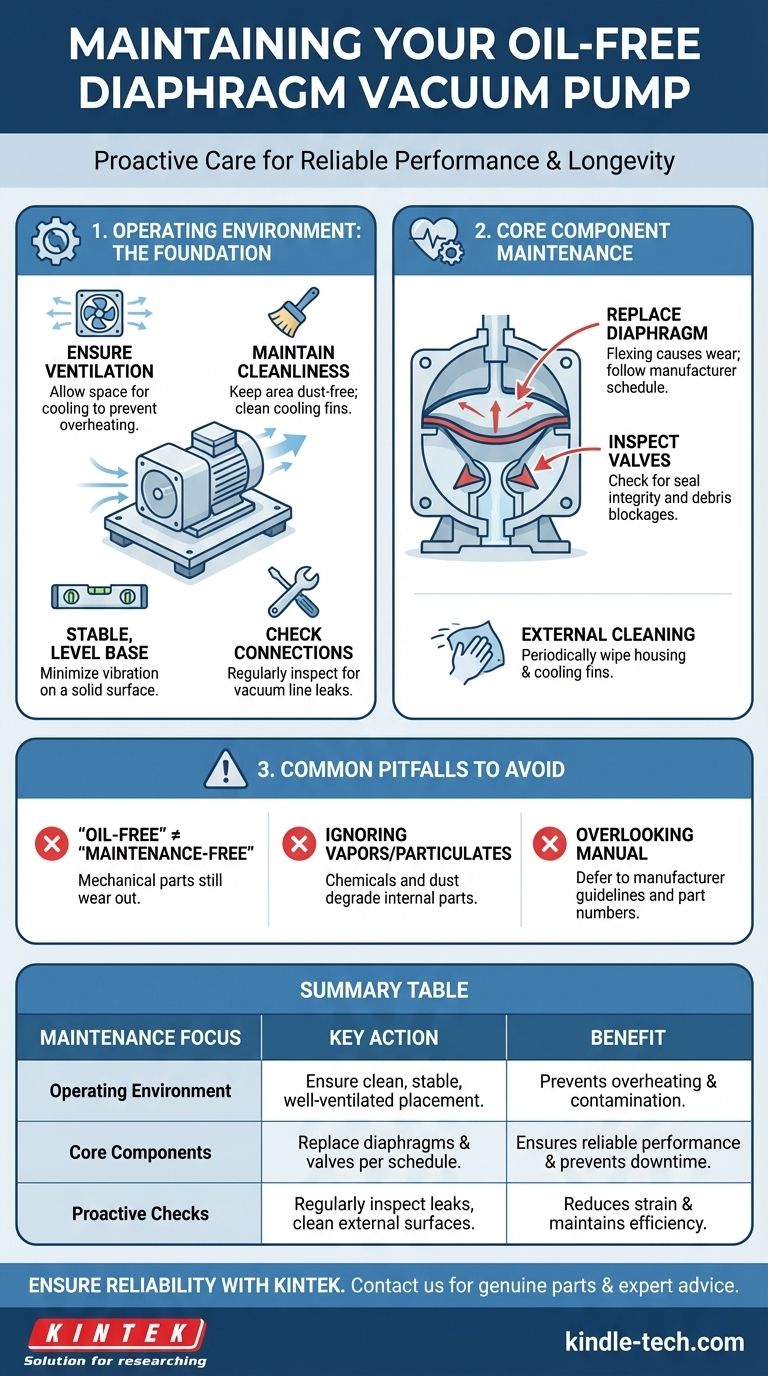

The Foundation: Your Pump's Operating Environment

Before any hands-on work, the single most effective maintenance strategy is ensuring the pump's environment is optimized for longevity. An ideal environment prevents the majority of common failures.

Ensure Proper Ventilation

The pump's motor and mechanical action generate heat. Placing it in an enclosed space without adequate airflow can lead to overheating, which accelerates the degradation of the diaphragm material and puts stress on motor components.

Always allow sufficient space around the pump for air to circulate freely.

Maintain a Clean Space

These pumps are oil-free, meaning they do not produce oily fumes. However, they are still susceptible to their environment. Dust and debris can clog cooling fins, acting as an insulator and causing the pump to run hot.

If installed in a dusty area, particulate matter can also be ingested, potentially damaging the sensitive internal valves.

Provide a Stable, Level Foundation

Diaphragm pumps create pressure pulses and have moving internal parts. Installing the unit on an uneven or flimsy surface will amplify vibration.

This constant vibration adds mechanical stress to the pump's housing, internal components, and, most critically, the plumbing connections, which can lead to leaks.

Check Pipeline Connections

A leak in the vacuum lines forces the pump to work harder and run longer to achieve the target vacuum level. This increases wear on the diaphragm and motor.

Regularly ensure all fittings and connections between the pump and your system are tight and free of leaks.

Core Maintenance Procedures

With a proper environment established, the active maintenance tasks are straightforward and focus on the pump's primary wear components.

The Diaphragm: The Heart of the Pump

The pump works by flexing a flexible diaphragm up and down via a motor-driven eccentric shaft. This action is what draws gas in and pushes it out.

This constant flexing means the diaphragm is the primary wear item. Over thousands of hours, the material will fatigue and eventually fail. Follow the manufacturer's service schedule for diaphragm replacement.

Valves: The Unsung Heroes

Small, one-way flap valves work in concert with the diaphragm to direct airflow into and out of the pumping chamber.

These valves can also wear out, lose their seal, or become blocked by ingested debris. They are typically inexpensive and are often replaced at the same time as the diaphragm as part of a standard service kit.

Regular External Cleaning

Periodically wipe down the pump's housing and, in particular, the motor's cooling fins. A clean surface radiates heat much more effectively than a dirty one.

This simple step is a powerful defense against overheating, especially in less-than-ideal environments.

Common Pitfalls and Misconceptions

Understanding what not to do is as important as knowing what to do. Avoiding these common mistakes will significantly extend your pump's reliable service life.

Misconception 1: "Oil-Free" Means "Maintenance-Free"

This is the most common error. Oil-free means you do not have to monitor or change lubricating oil. It does not mean the pump has no mechanical parts that wear out.

Ignoring the diaphragm's service life is the leading cause of unexpected failure and downtime.

Misconception 2: Ignoring Ingested Vapors or Particulates

While the pump has no oil to become contaminated, aggressive chemical vapors can still attack and degrade the diaphragm material. Likewise, solid particulates can score the diaphragm or prevent valves from sealing properly.

If your process generates aggressive vapors or dust, an appropriate inlet trap or filter is a critical, pump-saving accessory.

Misconception 3: Overlooking the Manufacturer's Manual

The user manual is your most important maintenance tool. It contains the specific service intervals for your model, the correct part numbers for service kits, and procedural diagrams.

Always defer to the manufacturer's instructions, as diaphragm materials and designs vary between models and applications.

Making the Right Choice for Your Goal

Your maintenance schedule should align with the pump's role in your work.

- If your primary focus is maximum longevity in a lab setting: Prioritize a clean, stable environment and strictly follow the manufacturer's diaphragm replacement schedule.

- If your primary focus is reliability in an industrial process: Implement frequent leak checks of all connections and consider installing an inlet filter to prevent particulate contamination.

- If your primary focus is optimal vacuum performance: Regularly inspect and clean the pump's valves, as even minor debris can compromise their seal and reduce the ultimate vacuum depth.

By focusing on these proactive measures, you shift from reacting to failures to ensuring consistent, reliable performance from your investment.

Summary Table:

| Maintenance Focus | Key Action | Benefit |

|---|---|---|

| Operating Environment | Ensure clean, stable, and well-ventilated placement. | Prevents overheating and contamination. |

| Core Components | Replace diaphragms and valves per manufacturer's schedule. | Ensures reliable performance and prevents downtime. |

| Proactive Checks | Regularly inspect for leaks and clean external surfaces. | Reduces strain on the pump and maintains efficiency. |

Ensure your lab's vacuum processes run reliably. Proper maintenance is key to protecting your investment. KINTEK specializes in lab equipment and consumables, offering the service kits, inlet filters, and expert support you need to keep your oil-free diaphragm pumps performing at their best.

Contact KINTEK today for genuine replacement parts and tailored advice to maximize your pump's service life.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What is the difference between glass tube and quartz tube? A Guide to Thermal & Optical Performance

- How do high-precision temperature controllers and thermocouples influence the conversion efficiency of Magnéli phase?

- What is the purpose of using a magnetic stirrer or shaker? Optimize Immobilized Bead Hardening & Consistency

- Why are zirconia grinding jars and balls required for sulfide electrolytes? Ensure Purity in Na3SbS4 & Na3PS4 Synthesis

- Why is a benchtop magnetic stirrer used in electrocoagulation? Enhance Wastewater Treatment Efficiency

- How much pressure can silica glass withstand? Design for Strength Beyond the Theoretical Limit

- Why use vacuum-sealed quartz ampoules for halide electrolyte synthesis? Ensure Purity & Stoichiometric Accuracy

- What is the cooling system in a furnace? Protecting Equipment and Ensuring Product Quality