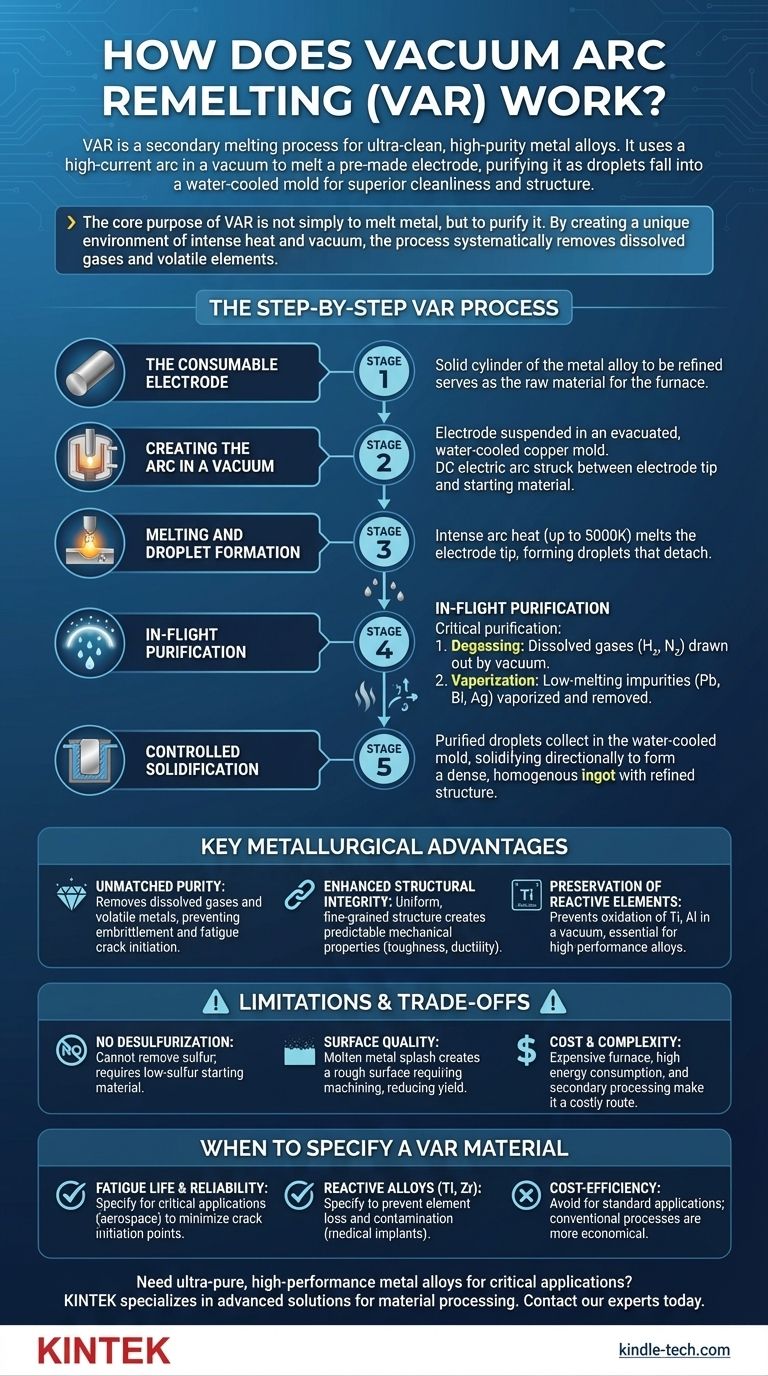

In short, Vacuum Arc Remelting (VAR) is a secondary melting process designed to produce ultra-clean, high-purity metal alloys. It functions by using a high-current electric arc inside a vacuum to melt a pre-made alloy electrode, allowing impurities to escape as the molten metal drips into a water-cooled copper mold. This controlled re-solidification results in a final ingot with superior cleanliness, a refined structure, and enhanced mechanical properties.

The core purpose of VAR is not simply to melt metal, but to purify it. By creating a unique environment of intense heat and vacuum, the process systematically removes dissolved gases and volatile elements that would otherwise compromise the material's strength, durability, and reliability.

The Step-by-Step VAR Process

To understand why VAR is essential for high-performance applications, it is helpful to visualize the process in distinct stages. Each step is engineered to contribute to the final ingot's purity and structural integrity.

Stage 1: The Consumable Electrode

The process begins with a solid cylinder of the metal alloy that needs to be refined. This is called the consumable electrode, and it serves as the raw material for the furnace.

Stage 2: Creating the Arc in a Vacuum

The electrode is vertically suspended inside a sealed, water-cooled copper mold. The entire chamber is evacuated to create a high vacuum. A DC electric arc is then struck between the bottom tip of the electrode and a small amount of starting material at the base of the mold.

Stage 3: Melting and Droplet Formation

The intense heat of the arc, which can approach 5000K, melts the tip of the consumable electrode. This molten metal forms into droplets that detach and fall from the electrode.

Stage 4: In-Flight Purification

This is the most critical stage for purification. As the droplets fall through the vacuum and pass through the high-temperature arc zone, two things happen:

- Degassing: Dissolved gases like hydrogen and nitrogen are drawn out by the vacuum.

- Vaporization: Low-melting-point metallic impurities, such as lead, bismuth, and silver, are vaporized and removed from the molten metal.

Stage 5: Controlled Solidification

The purified droplets collect in the water-cooled mold below, forming a molten pool. Because the mold is actively cooled, the metal solidifies directionally, from the outside-in and bottom-up. This controlled cooling minimizes chemical segregation and produces a dense, homogenous ingot with a refined crystal structure.

Key Metallurgical Advantages

The complexity of the VAR process is justified by the significant improvements it imparts to the final material.

Unmatched Purity

The primary benefit is the dramatic reduction of unwanted elements. Removing dissolved gases, particularly hydrogen, is critical for preventing embrittlement. Eliminating micro-inclusions and volatile metals produces a cleaner material that is far less prone to initiating fatigue cracks.

Enhanced Structural Integrity

The controlled, directional solidification creates a uniform and fine-grained ingot structure. This minimizes inconsistencies within the metal, leading to more predictable and reliable mechanical properties, such as toughness and ductility.

Preservation of Reactive Elements

For alloys containing highly reactive elements like titanium and aluminum, the vacuum environment is essential. It prevents these elements from oxidizing, ensuring they remain in the alloy to perform their intended function. This makes VAR suitable for producing titanium, zirconium, and their advanced alloys.

Understanding the Trade-offs and Limitations

No process is perfect, and being a trusted advisor means acknowledging the drawbacks. The decision to use VAR must account for its specific limitations.

No Desulfurization Capability

This is the most significant metallurgical limitation. The VAR process cannot remove sulfur. Therefore, the initial consumable electrode must already have a very low sulfur content, which often requires extra processing steps before the material even enters the VAR furnace.

Surface Quality and Yield

During remelting, molten metal can splash against the cold mold wall, creating a rough and porous ingot surface. This surface layer often has a higher concentration of impurities and must be machined or "peeled" off before further processing, reducing the final material yield.

Cost and Complexity

VAR furnaces are sophisticated and expensive to operate. The combination of high-vacuum systems, high energy consumption, and the need for secondary surface processing makes VAR a costly manufacturing route reserved for applications where performance justifies the expense.

When to Specify a VAR Material

Choosing a VAR-processed material is a deliberate engineering decision based on the demands of the final application. The designation "VAR" on a material specification sheet is a mark of high purity.

- If your primary focus is fatigue life and structural reliability: Specify VAR to minimize the internal micro-inclusions that act as initiation points for cracks, which is critical in aerospace components like landing gear and engine discs.

- If your primary focus is working with reactive alloys (e.g., Titanium, Zirconium): Specify VAR to prevent the loss of expensive alloying elements and contamination from atmospheric oxygen and nitrogen, which is essential for medical implants and chemical processing equipment.

- If your primary focus is cost-efficiency for a standard application: A VAR material is likely overkill, and more conventional melting processes will be sufficient and far more economical.

Ultimately, specifying a VAR material is a commitment to achieving the highest levels of purity and performance when failure is not an option.

Summary Table:

| Key Aspect | VAR Process Detail |

|---|---|

| Primary Goal | Purify and refine metal alloys for superior performance |

| Key Steps | 1. Vacuum creation 2. DC arc melting of electrode 3. In-flight degassing & vaporization 4. Controlled solidification in water-cooled mold |

| Main Advantages | Unmatched purity, removal of dissolved gases, enhanced structural integrity, preservation of reactive elements |

| Limitations | Cannot remove sulfur, high cost, requires surface finishing |

| Ideal For | Aerospace components, medical implants, reactive alloys (titanium, zirconium) |

Need ultra-pure, high-performance metal alloys for your critical applications? KINTEK specializes in advanced laboratory equipment and consumables, including solutions for high-purity material processing. Whether you're developing aerospace components, medical implants, or specialized alloys, our expertise can help you achieve the material integrity and reliability your projects demand. Contact our experts today to discuss how we can support your laboratory's most challenging needs.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the temperature of a heat treatment furnace? It's Dictated by Your Material and Process Goals

- What is vacuum heat treating? Achieve Superior Metallurgical Purity and Surface Integrity

- What are the functions of a vacuum high-temperature furnace? Master Diffusion Bonding for Titanium Alloys

- Why is a vacuum chamber and heating system maintained at 300°C during deposition? Optimize Coating Adhesion

- What role does the crystallizer perform in magnesium recovery? Master Pure Sublimation and Yield

- What is the voltage of a vacuum arc? Discover the Low, Stable Voltage for Superior Performance

- Why is a high vacuum required for Mo2Ga2C sintering? Ensure Maximum Phase Purity and Density

- What is a vacuum brazing furnace? Achieve Flawless, High-Strength Joining