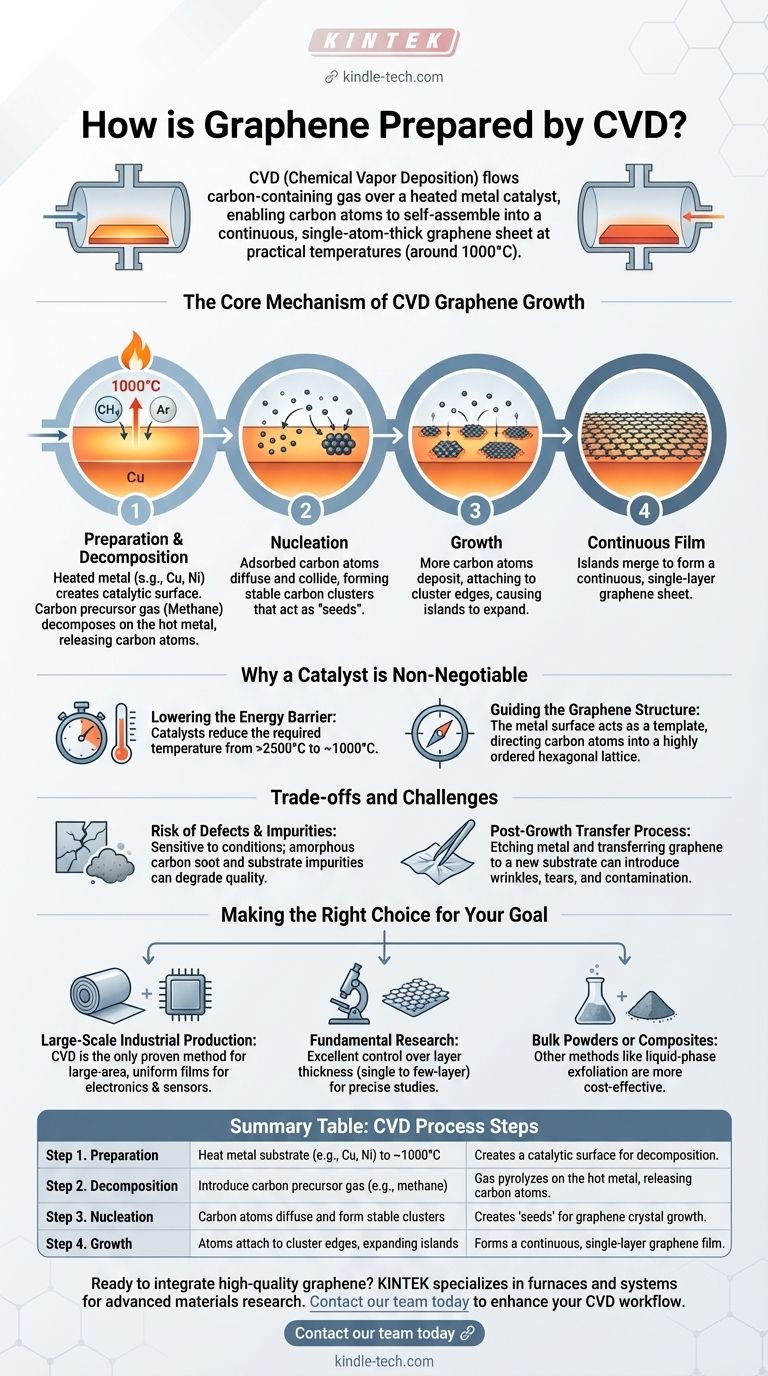

In essence, preparing graphene via Chemical Vapor Deposition (CVD) involves flowing a carbon-containing gas, like methane, over a hot metal catalyst, typically copper or nickel. At temperatures around 1000°C, the gas decomposes, and carbon atoms deposit onto the metal surface, self-assembling into a continuous, single-atom-thick sheet of graphene. The metal substrate acts as both a surface for the reaction and a catalyst that makes the process possible at practical temperatures.

Chemical Vapor Deposition is less about simply depositing carbon and more about using a heated metal catalyst as a template. The process guides individual carbon atoms from a gas precursor into a highly ordered, large-area hexagonal lattice, making it the most viable method for producing high-quality graphene for industrial applications.

The Core Mechanism of CVD Graphene Growth

The CVD process can be broken down into a series of precise, sequential steps. Each stage is critical for controlling the final quality and uniformity of the graphene film.

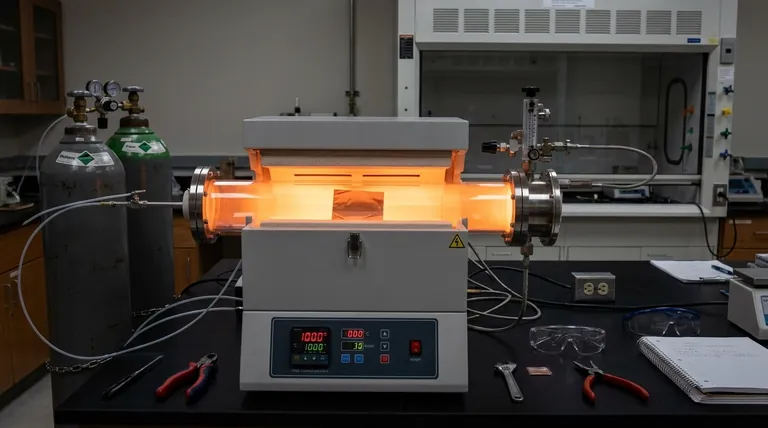

### Setting the Stage: The Key Ingredients

Before growth can begin, a specific environment must be established inside a reactor chamber. This requires a carbon source (precursor), a catalytic surface, and carrier gases to manage the atmosphere.

The primary components are a hydrocarbon precursor (methane is common), a catalytic metal substrate (copper and nickel are widely used), and inert carrier gases like Argon or Hydrogen.

### Step 1: Precursor Pyrolysis and Adsorption

The process starts by heating the metal substrate to a high temperature, typically around 1000°C. The carbon precursor gas is then introduced into the chamber.

The intense heat causes the precursor gas to decompose into highly reactive carbon atoms or radicals. Critically, this breakdown must happen on the hot metal surface, not in the gas phase, to prevent the formation of useless carbon soot. These carbon atoms then adsorb onto the catalyst.

### Step 2: Nucleation and Growth

Once adsorbed, the individual carbon atoms are not static. They diffuse and move across the catalyst's surface.

Eventually, these mobile atoms collide and begin forming small, stable carbon clusters. These clusters act as "seeds" or nucleation sites from which the graphene crystal starts to grow.

### Step 3: Forming a Continuous Film

As more carbon atoms deposit onto the surface, they attach to the edges of these initial graphene islands.

The islands expand outwards across the substrate until they meet and merge, ultimately forming a continuous, unbroken sheet of single-layer graphene that covers the entire surface of the metal catalyst.

Why a Catalyst is Non-Negotiable

The metal substrate is not merely a passive surface for deposition; it is an active and essential catalyst that makes the entire process feasible.

### Lowering the Energy Barrier

Without a catalyst, the formation of a stable graphitic structure from carbon atoms requires temperatures exceeding 2500°C. Such conditions are impractical and enormously energy-intensive.

Catalysts like copper and nickel dramatically lower this energy barrier, allowing high-quality graphene to form at a much more manageable temperature of around 1000°C.

### Guiding the Graphene Structure

The choice of catalyst directly influences the deposition mechanism and the resulting graphene quality. The specific properties of the metal surface guide how the carbon atoms arrange themselves into the desired hexagonal lattice, impacting everything from grain size to layer uniformity.

Understanding the Trade-offs and Challenges

While CVD is powerful, it is a complex process with technical hurdles that must be managed to achieve a high-quality final product.

### The Risk of Defects and Impurities

The process is highly sensitive to conditions. If precursor pyrolysis occurs in the gas phase instead of on the substrate, it creates amorphous carbon soot that can fall onto the graphene film and degrade its quality.

Any imperfections or impurities on the initial metal substrate can also translate into defects in the final graphene sheet.

### The Post-Growth Transfer Process

Graphene is grown on a metal catalyst but is typically needed on an insulating substrate like silicon for electronic applications. This requires a delicate transfer process.

The metal is etched away, and the fragile, one-atom-thick graphene film must be moved to its new substrate. This step is a major source of wrinkles, tears, and contamination that can compromise the material's exceptional properties.

Making the Right Choice for Your Goal

Selecting a synthesis method depends entirely on the desired outcome, as different techniques are optimized for different end-uses.

- If your primary focus is large-scale industrial production: CVD is the only proven method for creating the uniform, large-area graphene films required for electronics, sensors, and transparent conductive films.

- If your primary focus is fundamental research: CVD provides excellent control over layer thickness (from single to few-layer), enabling precise studies of graphene's unique electronic and physical properties.

- If your primary focus is creating bulk powders or composites: Other methods like liquid-phase exfoliation are often more cost-effective for applications that do not require a perfect, large-area film.

Ultimately, understanding the CVD process reveals it as a masterpiece of controlled catalysis, capable of turning a simple gas into a revolutionary two-dimensional material.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Preparation | Heat metal substrate (e.g., Cu, Ni) to ~1000°C | Creates a catalytic surface for decomposition. |

| 2. Decomposition | Introduce carbon precursor gas (e.g., methane) | Gas pyrolyzes on the hot metal, releasing carbon atoms. |

| 3. Nucleation | Carbon atoms diffuse and form stable clusters | Creates 'seeds' for graphene crystal growth. |

| 4. Growth | Atoms attach to cluster edges, expanding islands | Forms a continuous, single-layer graphene film. |

Ready to integrate high-quality graphene into your research or product development? The precise control required for successful CVD synthesis depends on reliable lab equipment. KINTEK specializes in furnaces, gas handling systems, and consumables essential for advanced materials research, including graphene growth. Our experts can help you configure the right setup for your specific catalytic process and scalability goals.

Contact our team today to discuss how our solutions can enhance your CVD workflow and accelerate your materials innovation.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the chemical vapor deposition method of carbon? Build Advanced Materials from the Atoms Up

- What are the components of the CVD system? A Guide to the Core Modules for Thin Film Deposition

- How does RF sputtering compare to DC sputtering in terms of deposition rate and cost? Maximize Your Lab Throughput

- What are sputtering systems? A Guide to High-Quality Thin Film Deposition

- What is CVD and application? Unlock High-Performance Materials with Chemical Vapor Deposition

- What does CVD stand for in vapor deposition? Unlock the Power of Chemical Vapor Deposition

- Why do we need vacuum while doing coatings? Achieve Superior Purity and Adhesion

- What advantages does CVD equipment offer for depositing Pt on TiO2? Atomic Precision for Superior Performance