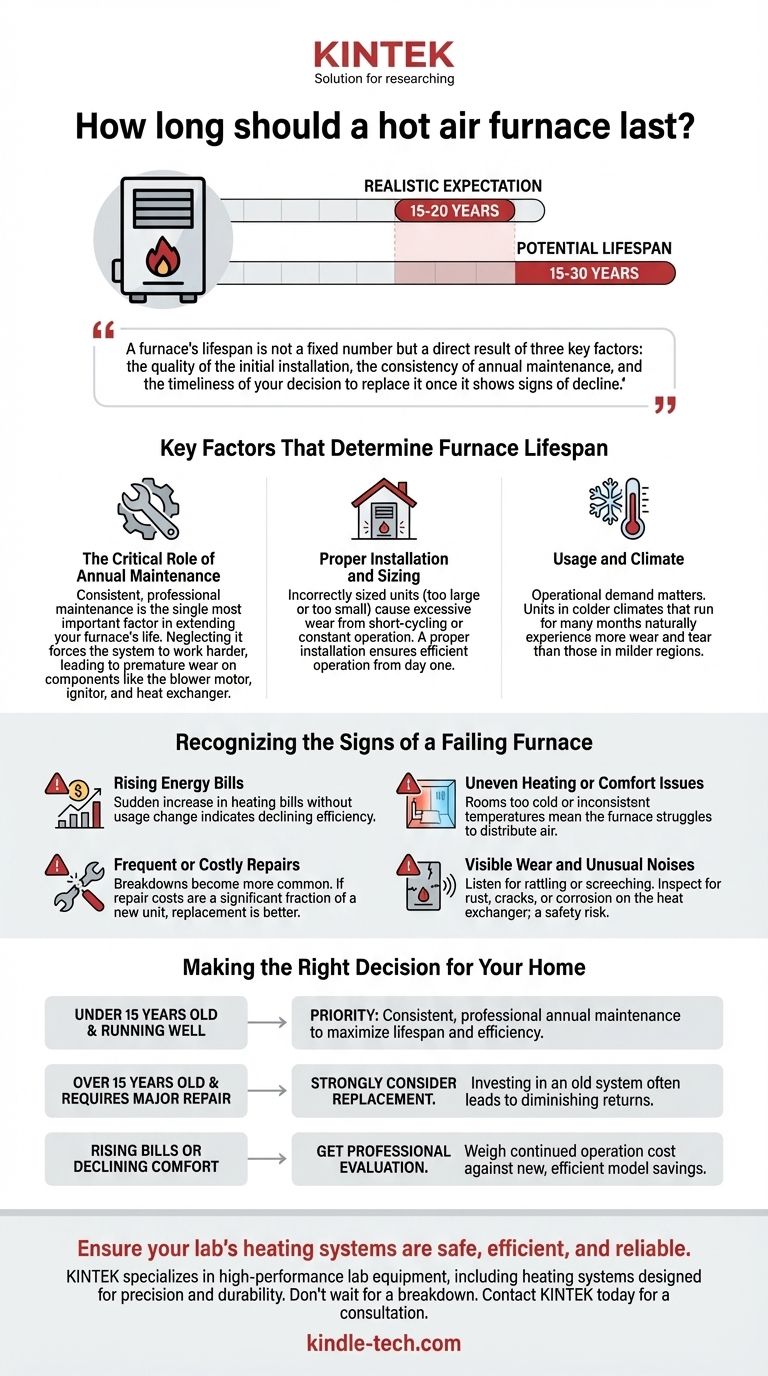

On average, a modern hot air furnace should last between 15 and 30 years. However, a more realistic expectation for most units, even with proper care, is closer to 15 to 20 years. Factors like the quality of the installation, your maintenance schedule, and climate all play a significant role in determining where your specific unit will fall within this range.

A furnace's lifespan is not a fixed number but a direct result of three key factors: the quality of the initial installation, the consistency of annual maintenance, and the timeliness of your decision to replace it once it shows signs of decline.

Key Factors That Determine Furnace Lifespan

Simply knowing the average lifespan isn't enough. To truly understand your furnace's health, you must consider the elements that directly impact its longevity and performance.

The Critical Role of Annual Maintenance

Consistent, professional maintenance is the single most important factor in extending your furnace's life. Neglecting it forces the system to work harder to produce the same amount of heat.

This strain leads to premature wear on critical components like the blower motor, ignitor, and heat exchanger, significantly shortening the unit's operational life.

Proper Installation and Sizing

A furnace that is incorrectly sized for your home—either too large or too small—will not last as long. An oversized unit will cycle on and off too frequently (short-cycling), causing excessive wear.

An undersized unit will run almost constantly, straining its components to keep up. A proper installation by a qualified technician ensures the furnace operates as efficiently as intended from day one.

Usage and Climate

The operational demand on your furnace has a direct impact. A unit in a cold northern climate that runs for many months of the year will naturally experience more wear and tear than a furnace in a milder region.

Recognizing the Signs of a Failing Furnace

Age is just one indicator. A furnace's performance and repair history often provide a clearer signal that it's nearing the end of its life. Be watchful for these warning signs.

Rising Energy Bills

A sudden or steady increase in your heating bills, without a corresponding change in your usage, is a classic sign of declining efficiency. The furnace is consuming more fuel to produce the same amount of heat.

Frequent or Costly Repairs

As a furnace ages, breakdowns become more common. If you find yourself calling for repairs every year, or if you're facing a repair bill that is a significant fraction of a new unit's cost, replacement is often the more financially sound decision.

Uneven Heating or Comfort Issues

Rooms that are suddenly too cold, or a system that can't seem to maintain a consistent temperature, indicate the furnace is struggling to distribute air effectively.

Visible Wear and Unusual Noises

Listen for new sounds like rattling, popping, or screeching. Visually inspect the unit for rust, cracks, or corrosion, especially on or around the heat exchanger, as this can pose a serious safety risk.

Understanding the Trade-offs: Repair vs. Replace

Deciding whether to fix an aging furnace or invest in a new one involves weighing short-term costs against long-term benefits and safety.

The Cost of Inefficiency

Continuing to run an older, inefficient furnace means you are overpaying for fuel every month. A new, high-efficiency furnace can significantly lower your energy bills, and these savings help offset the upfront investment over time.

The Safety Factor

The most significant risk in an old furnace is a cracked heat exchanger. This can allow dangerous carbon monoxide (CO) to leak into your home's air supply. This risk alone is often the deciding factor in replacing a furnace that is over 20 years old.

Parts and Reliability

For very old furnaces, sourcing replacement parts can become difficult and expensive. Investing a large sum to repair an old unit provides no guarantee that another component won't fail next winter.

Making the Right Decision for Your Home

Use your furnace's age and performance to guide your strategy. Your goal should be to replace the unit on your own terms, not in an emergency situation mid-winter.

- If your furnace is under 15 years old and running well: Your priority is consistent, professional annual maintenance to maximize its lifespan and efficiency.

- If your furnace is over 15 years old and requires a major repair: You should strongly consider a replacement, as investing in an old system often leads to diminishing returns.

- If you notice rising energy bills or declining comfort: It is time to get a professional evaluation to weigh the cost of continued operation against the long-term savings of a new, efficient model.

Proactively managing your furnace's lifecycle empowers you to ensure your home remains safe, comfortable, and efficient.

Summary Table:

| Factor | Impact on Lifespan | Key Insight |

|---|---|---|

| Annual Maintenance | High | The most critical factor. Neglect causes premature wear on key components. |

| Installation & Sizing | High | Incorrect sizing leads to short-cycling or constant strain, reducing longevity. |

| Usage & Climate | Moderate | Units in colder climates that run more frequently experience more wear. |

| Age & Repair History | Critical | Frequent repairs or bills over 50% of a new unit's cost signal replacement time. |

Ensure your lab's heating systems are safe, efficient, and reliable.

An inefficient or failing furnace doesn't just risk comfort—it can compromise critical experiments and lab safety. KINTEK specializes in high-performance lab equipment, including heating systems designed for precision and durability.

Our experts can help you select the right equipment to maintain consistent temperatures, reduce energy costs, and ensure a safe environment for your work.

Don't wait for a breakdown. Contact KINTEK today for a consultation and ensure your lab's heating needs are met with reliability and efficiency.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is a muffle furnace used for ash determination? Achieve Precise Inorganic Analysis

- What is the effect of calcination temperature on the properties of nanoparticles? Master the Trade-Off for Optimal Performance

- What is the hottest temperature a furnace can be? Exploring Limits from 3,000°C+ to Your Application

- How do you set up a muffle furnace? A Step-by-Step Guide for Safe and Accurate Operation

- What is the lab safety of heat? A Complete Guide to Preventing Burns and Fires