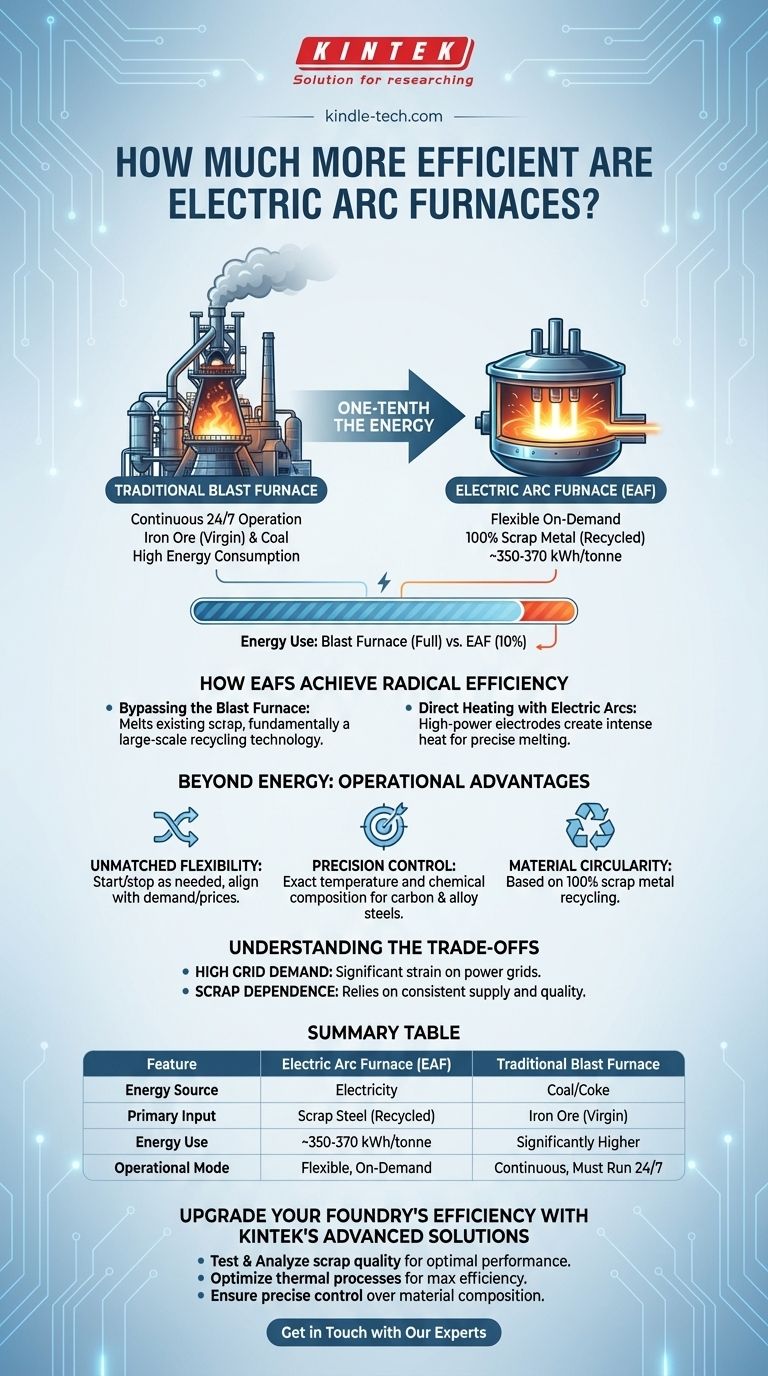

From an energy standpoint, the difference is staggering. An Electric Arc Furnace (EAF) requires only one-tenth of the energy needed by a traditional blast furnace to produce the same amount of steel. This dramatic reduction in energy intensity stems from a fundamental difference in how each technology approaches steelmaking.

The core efficiency of an Electric Arc Furnace isn't just an incremental improvement; it represents a complete paradigm shift from producing steel with raw materials to recycling it with electricity, offering profound gains in energy use, material circularity, and operational agility.

How EAFs Achieve Radical Efficiency

The incredible efficiency of an EAF is not based on a single component but on its entire operational philosophy. It redefines the steelmaking process by changing the primary input from raw iron ore to recycled scrap metal.

Bypassing the Blast Furnace

A traditional integrated steel mill uses a blast furnace to convert iron ore into iron, a process that is enormously energy-intensive and must run continuously. This process requires creating coke from coal and involves multiple high-temperature chemical reactions.

The EAF completely sidesteps this. Its primary function is to melt existing steel scrap, which requires significantly less energy than creating new steel from raw materials. It is fundamentally a large-scale recycling technology.

Direct Heating with Electric Arcs

The EAF uses high-power graphite electrodes to create an electrical arc directly to the scrap metal inside. This arc generates intense heat, melting the metal with high precision and control.

This direct application of energy is far more efficient than the complex, multi-stage chemical reduction process that occurs inside a blast furnace. The typical energy required is around 350 to 370 kWh per tonne of steel produced.

Beyond Energy: The Operational Advantages

While energy savings are the most cited benefit, the EAF model provides crucial advantages in flexibility and control that are simply not possible with older technologies.

Unmatched Operational Flexibility

Blast furnaces must operate continuously for months or even years at a time; stopping and restarting them is a monumental and costly task.

In contrast, an EAF can be started and stopped as needed. This allows producers to align production directly with market demand or even with fluctuating electricity prices, a significant economic advantage.

Precision and Material Control

The EAF process allows for highly accurate control over the temperature and chemical composition of the molten steel.

This precision makes it ideal for producing a wide variety of carbon and alloy steels to exact specifications. It can achieve a level of quality control that is critical for specialized applications.

Understanding the Trade-offs

No technology is without its limitations. The efficiency of the EAF comes with its own set of specific requirements and challenges that must be managed.

High Demand on the Electrical Grid

While the total energy consumed is far lower than a blast furnace, an EAF consumes a massive amount of electricity in a very short period. This can place a significant strain on local power grids if not managed properly.

Foundries using EAFs must work closely with utility providers and often schedule their operations to avoid peak demand periods to maintain efficiency and grid stability.

Dependence on Scrap Metal

The EAF model is built on the foundation of 100% scrap metal recycling. Its efficiency and environmental benefits are directly tied to the availability and quality of ferrous scrap.

This creates a dependency on a consistent supply chain for recycled steel, which can be subject to market fluctuations in price and availability.

Making the Right Choice for Your Goal

The choice between steelmaking technologies depends entirely on the strategic objective, available resources, and market focus.

- If your primary focus is minimizing direct energy consumption and CO2 emissions: The EAF is the undisputed choice due to its reliance on electricity and recycled materials.

- If your primary focus is operational agility and producing specialized steel grades: The on-demand nature and precise control of the EAF make it the superior technology.

- If your primary focus is producing virgin steel from iron ore at a massive, continuous scale: The traditional blast furnace route remains the established, albeit far more energy-intensive, method.

Ultimately, the Electric Arc Furnace represents a more sustainable, flexible, and efficient future for the steel industry.

Summary Table:

| Feature | Electric Arc Furnace (EAF) | Traditional Blast Furnace |

|---|---|---|

| Energy Source | Electricity | Coal/Coke |

| Primary Input | Scrap Steel (Recycled) | Iron Ore (Virgin Material) |

| Energy Use | ~350-370 kWh/tonne | Significantly Higher |

| Operational Mode | Flexible, On-Demand | Continuous, Must Run 24/7 |

| Key Advantage | Energy Efficiency, Material Circularity | Large-Scale Virgin Steel Production |

Upgrade Your Foundry's Efficiency with KINTEK's Advanced Solutions

Are you looking to reduce energy costs, improve operational flexibility, or enhance your steel recycling capabilities? KINTEK specializes in high-performance laboratory and industrial equipment, including systems that support advanced material testing and process optimization for modern steel production.

Our expertise can help you:

- Test and analyze scrap metal quality for optimal EAF performance.

- Optimize thermal processes to maximize energy efficiency.

- Ensure precise control over material composition and quality.

Whether you're in R&D, quality control, or production, KINTEK has the equipment and consumables to support your goals. Contact us today to discuss how we can help you leverage EAF technology for a more sustainable and profitable operation.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is sputter coated glass? Discover High-Performance Solar Control Technology

- What is the sputtering yield of materials? Master Deposition Rates & Film Quality

- What are the limitations of diamonds? Beyond the Myth of Perfection

- What is the KBr method? A Guide to FTIR Sample Prep for Solid Materials

- What does CIP stand for Crip? Understanding the Meaning of Crip In Peace

- What is sintering process in blast furnace? Transform Iron Ore Fines into High-Performance Feedstock

- What are the three factors of heat treatment? Master Temperature, Time & Cooling Rate

- What function do specific salts perform in MS3 synthesis? Unlock Cost-Effective MAX Phase Production