Proper maintenance of a titanium electrode centers on a disciplined routine of inspection, gentle cleaning, and periodic acid washing. The key is to regularly immerse the electrode in a 5-10% dilute hydrochloric acid solution for about 30 minutes every 100-200 operating hours to remove scale, followed by a thorough rinse with deionized water and careful storage.

The goal of all maintenance is not merely to clean the electrode, but to preserve the integrity of its specialized catalytic coating. This delicate surface is responsible for the electrode's performance and lifespan, and every action must be taken with its protection in mind.

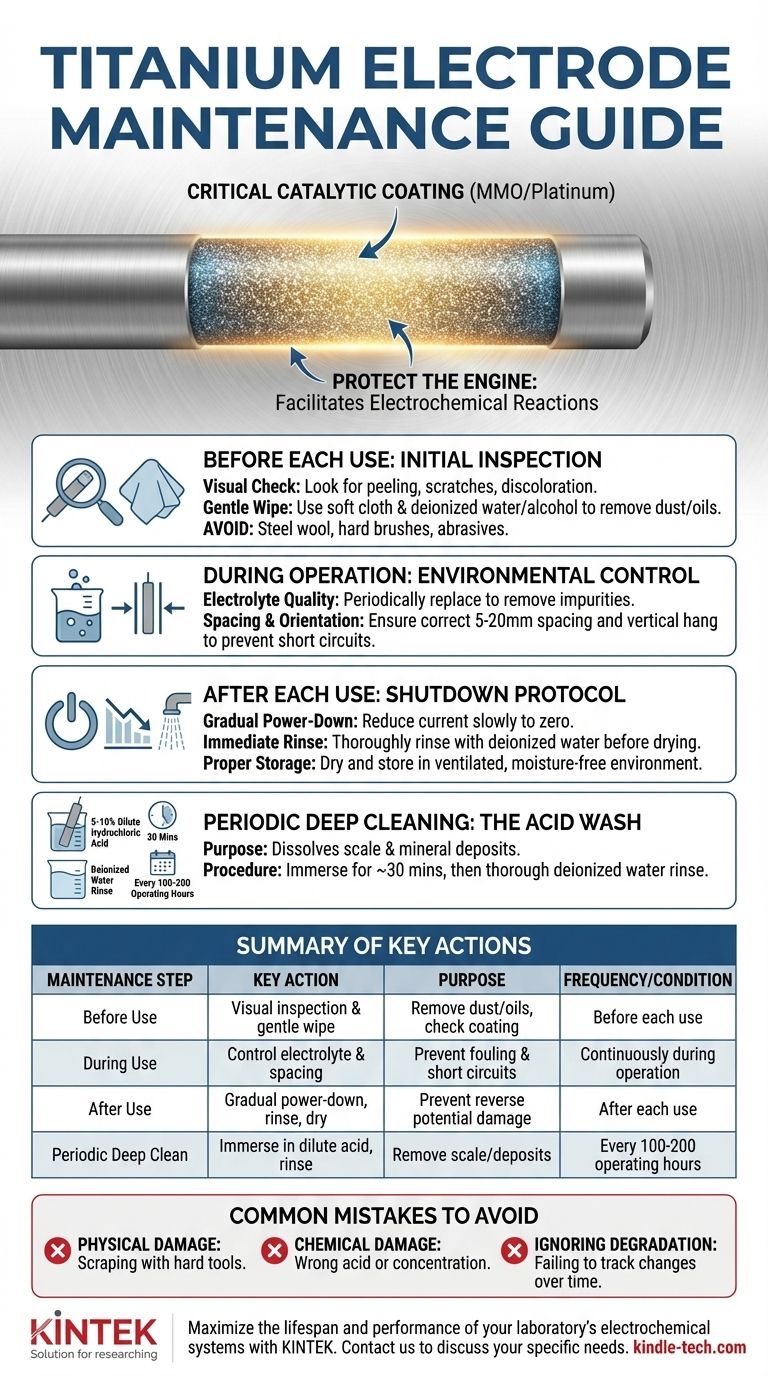

The Core Principle: Protecting the Catalytic Coating

The effectiveness of a titanium electrode doesn't come from the titanium itself, but from the thin layer of mixed metal oxides (MMO) or platinum coated onto its surface. All maintenance procedures are designed to protect this critical layer.

The Coating is the Engine

This coating acts as a catalyst, facilitating the desired electrochemical reactions. Without it, the electrode is just a piece of corrosion-resistant metal with poor catalytic activity.

Contamination is the Enemy

During operation, scale, precipitates, and impurities from the electrolyte can build up on the coating. This fouling blocks active sites, reduces efficiency, increases power consumption, and can ultimately lead to permanent damage.

A Practical Maintenance Framework

A consistent maintenance schedule is the most effective way to ensure longevity and reliable performance. This framework covers actions before, during, after, and between uses.

Before Each Use: Initial Inspection

First, visually inspect the coating. Look for any signs of peeling, scratching, bubbling, or significant discoloration.

Gently wipe the surface with a soft cloth and deionized water or alcohol. This removes dust or oils that could interfere with the reaction. Never use steel wool, hard brushes, or abrasive tools, as they will permanently scratch and damage the coating.

During Operation: Environmental Control

The electrolyte is the electrode's operating environment. Periodically replacing the electrolyte is crucial to remove impurity precipitates that can foul the coating.

Also, ensure the electrode spacing is set correctly (typically 5-20mm) and that the electrodes hang vertically. This prevents short circuits that can cause immediate and severe damage.

After Each Use: The Shutdown Protocol

Gradually reduce the current to zero before shutting off the power supply. Abruptly cutting power can create a reverse potential, which can strip or damage the delicate coating.

Immediately after power-down, rinse the electrode thoroughly with deionized water. This removes residual electrolyte before it can dry, crystallize, and cause corrosion.

Finally, dry the electrode and store it in a ventilated, moisture-free environment away from any corrosive gases.

Periodic Deep Cleaning: The Acid Wash

For routine, heavy-duty cleaning, an acid wash is required every 100-200 operating hours.

Immerse the electrode in a 5% to 10% solution of dilute hydrochloric acid for approximately 30 minutes. This process dissolves scale and mineral deposits without aggressively attacking the coating itself.

After the acid bath, rinse the electrode thoroughly with deionized water to remove all traces of acid before drying and storage.

Understanding the Risks and Common Pitfalls

Improper maintenance is worse than no maintenance at all. Understanding the potential for error is critical to avoiding costly mistakes.

The Danger of Physical Damage

The most common mistake is using mechanical force for cleaning. The catalytic coating is extremely thin and fragile. Scraping it with hard tools will cause irreparable damage and render the electrode useless.

The Risk of Chemical Damage

While a dilute acid wash is prescribed, using the wrong acid, a higher concentration, or leaving the electrode immersed for too long can dissolve the coating itself. Always adhere to the recommended concentration and time.

Ignoring Gradual Degradation

An electrode rarely fails overnight. Failure is a process of slow degradation. Keep a log of operating hours, visual changes in the coating, and any fluctuations in performance. This data helps you anticipate when an electrode is nearing the end of its life.

How to Apply This to Your Process

Your maintenance strategy should align directly with your operational priorities.

- If your primary focus is maximizing electrode lifespan: Prioritize the shutdown protocol and proper storage. Preventing damage from reverse potential and corrosion is the single most effective way to extend its service life.

- If your primary focus is ensuring consistent performance: Emphasize the periodic deep cleaning and regular electrolyte replacement. This prevents the gradual buildup of scale that leads to decreased efficiency and inconsistent results.

Proactive and correct maintenance transforms your titanium electrode from a simple consumable into a reliable, long-term asset.

Summary Table:

| Maintenance Step | Key Action | Purpose | Frequency/Condition |

|---|---|---|---|

| Before Use | Visual inspection & gentle wipe with soft cloth/deionized water | Remove dust/oils, check for coating damage | Before each use |

| During Use | Control electrolyte quality and electrode spacing | Prevent fouling and short circuits | Continuously during operation |

| After Use | Gradual power-down, immediate rinse with deionized water, dry storage | Prevent reverse potential damage and corrosion | After each use |

| Periodic Deep Clean | Immerse in 5-10% dilute hydrochloric acid for ~30 mins, then rinse thoroughly | Remove scale and mineral deposits | Every 100-200 operating hours |

Maximize the lifespan and performance of your laboratory's electrochemical systems. Proper maintenance is key to protecting your valuable titanium electrodes. KINTEK specializes in high-quality lab equipment and consumables, including electrodes designed for durability. Our experts can help you establish an optimal maintenance routine to ensure consistent results and protect your investment.

Contact KINTEL today to discuss your laboratory's specific needs and discover how our solutions can enhance your processes.

Visual Guide

Related Products

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Vertical Laboratory Tube Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What precautions should be taken regarding temperature control with a five-port water bath electrolytic cell? Ensure Safe and Accurate Electrochemical Experiments

- What are the procedures for after using a double-layer water-bath electrolytic cell? Ensure Equipment Longevity and Data Accuracy

- How does the design of an electrolytic cell influence evaluation of electrochemical catalytic performance? Key Factors

- How should a double-layer water-bath electrolytic cell be operated? A Step-by-Step Guide for Reliable Results

- What does the routine maintenance of a double-layer water-bath electrolytic cell involve? A Guide to Ensuring Precision and Longevity