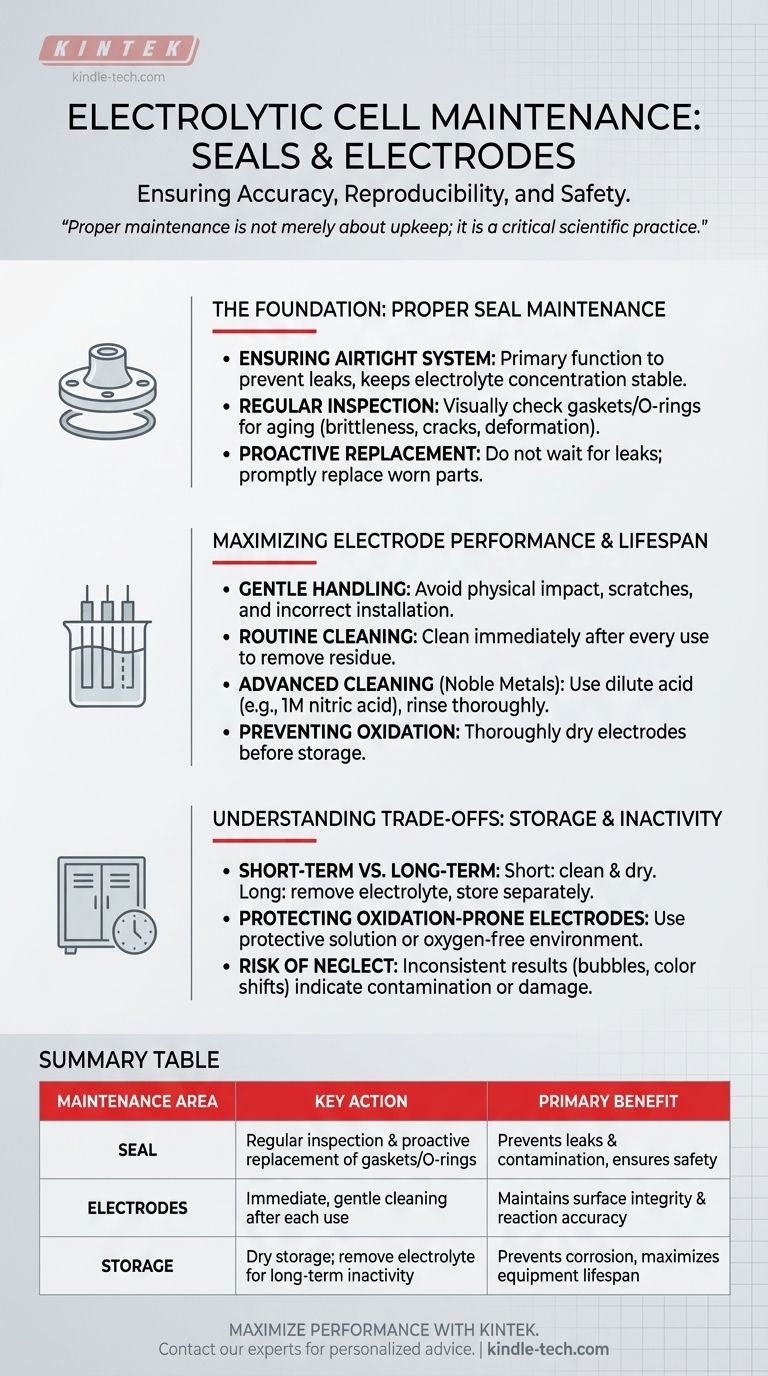

To maintain an electrolytic cell, you must ensure its seal is consistently tight and replace any aged components to prevent leaks. For the electrodes, the key is to clean them immediately after each use, handle them with care to prevent physical damage, and store them in a dry environment to inhibit corrosion and contamination.

Proper maintenance is not merely about upkeep; it is a critical scientific practice. The integrity of your seals and the condition of your electrodes directly determine the accuracy, reproducibility, and safety of your experimental results.

The Foundation: Proper Seal Maintenance

A compromised seal can invalidate an entire experiment. Its maintenance is your first line of defense against systemic error and potential hazards.

### Ensuring an Airtight System

The primary function of the seal is to prevent leaks. A tight seal ensures that the electrolyte concentration remains stable and that no external contaminants enter the system.

Regularly verify that all sealing components are securely fastened before beginning any experiment.

### The Importance of Regular Inspection

Sealing materials like gaskets and O-rings degrade over time due to chemical exposure and mechanical stress.

Visually inspect these parts for signs of aging, such as brittleness, cracks, or deformation. This simple check can prevent catastrophic failure during a critical process.

### When to Replace Sealing Components

Do not wait for a leak to occur. Promptly replace any sealing part that appears worn or damaged.

Adopting a proactive replacement schedule for these components is a cost-effective strategy to protect your experiments and equipment.

Maximizing Electrode Performance and Lifespan

Electrodes are the active heart of the cell. Their surface condition dictates the efficiency and accuracy of the electrochemical reaction.

### Gentle Handling and Installation

The surfaces of your electrodes are sensitive. Avoid collisions, scratches, or any physical impact that could alter their surface area or catalytic properties.

During installation, carefully align the electrodes to ensure they do not touch the cell walls or bottom, then tighten clamps securely.

### Routine Cleaning After Every Use

Clean the electrodes and reaction vessel immediately after each experiment. This prevents the buildup of reaction products and residue.

Using an appropriate cleaning agent or solvent is crucial for removing surface dirt and oxides without damaging the electrode material itself.

### Advanced Cleaning for Noble Metals

For noble metal electrodes, such as platinum, a more specific cleaning protocol may be necessary to restore performance.

A common method is to soak the electrode in a dilute acid (e.g., 1M nitric acid), followed by a thorough rinsing with deionized water to remove any trace of the acid.

### Preventing Contamination and Oxidation

Prolonged exposure to air and moisture can degrade electrode surfaces. Always dry electrodes thoroughly after cleaning and before storage.

This simple step is critical for preventing oxidation and other forms of chemical deterioration that can skew experimental data.

Understanding the Trade-offs: Storage and Inactivity

How you store your cell and electrodes between uses has a significant impact on their long-term viability.

### Short-Term vs. Long-Term Storage

For short periods of inactivity, ensuring the components are clean and dry in a non-humid environment is sufficient.

For long-term storage, pour the electrolyte out of the cell and store it in a separate, sealed container. This prevents slow, corrosive reactions and preserves both the electrolyte and the cell.

### Protecting Oxidation-Prone Electrodes

Certain metal electrodes are highly susceptible to oxidation. Extra precautions are required for their storage.

Store these sensitive electrodes by either immersing them in a protective solution containing an antioxidant or by keeping them in a dry, oxygen-free environment.

### The Risk of Neglecting Inspection

A decline in electrode performance is the most common consequence of poor maintenance.

If you observe inconsistent results, such as changes in bubble formation or unexpected color shifts, it is a clear sign that the electrodes may be contaminated or damaged and require immediate attention, treatment, or replacement.

Applying This to Your Workflow

Your maintenance strategy should align with your primary experimental goals.

- If your primary focus is experimental accuracy: Prioritize immediate, thorough cleaning of electrodes after every use to prevent cross-contamination and residue buildup.

- If your primary focus is long-term equipment lifespan: Emphasize proper storage protocols, especially removing electrolyte for long-term inactivity and keeping all components completely dry.

- If your primary focus is safety and reliability: Make regular, detailed inspection of all seals and gaskets a non-negotiable part of your pre-experiment checklist to prevent leaks.

Systematic maintenance transforms your electrolytic cell from a potential variable into a reliable constant.

Summary Table:

| Maintenance Area | Key Action | Primary Benefit |

|---|---|---|

| Seal | Regular inspection & proactive replacement of gaskets/O-rings | Prevents leaks and contamination, ensures safety |

| Electrodes | Immediate, gentle cleaning after each use | Maintains surface integrity and reaction accuracy |

| Storage | Dry storage; remove electrolyte for long-term inactivity | Prevents corrosion, maximizes equipment lifespan |

Maximize the performance and lifespan of your laboratory equipment. Proper maintenance is key to reliable data. KINTEK specializes in high-quality lab equipment and consumables, including electrolytic cells and replacement parts, to support your research needs.

Contact our experts today for personalized advice and to ensure your lab operates at peak efficiency.

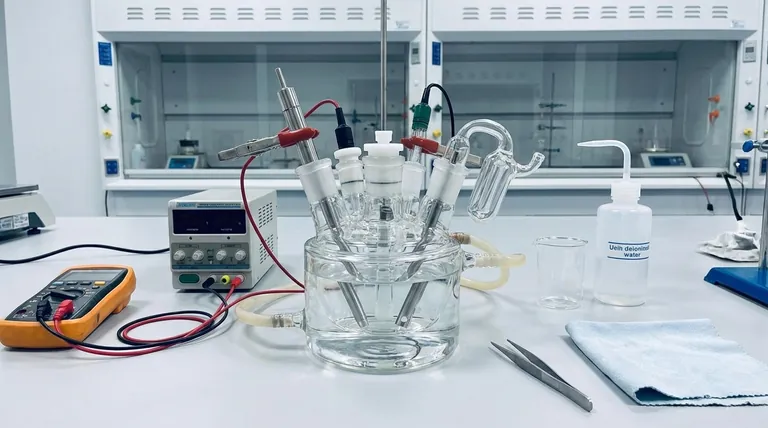

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- H Type Electrolytic Cell Triple Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- How can the electrochemical reaction be controlled when using this electrolytic cell? Master Voltage, Current & Electrolyte

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup

- What are the standard aperture specifications of the electrolytic cell? Key Sizes for Your Electrochemical Setup

- When is professional repair required for a double-layer water-bath electrolytic cell? Protect Your Lab's Precision and Safety

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments