In short, increasing the amplitude of shaking generally improves the efficiency of particle separation, especially for finer particles, by providing more energy to move them through the sieve stack. However, excessive amplitude is counterproductive; it can cause particle attrition (breakage), which artificially creates more fines and skews your results, or cause particles to bounce so high they rarely contact the sieve mesh.

The core challenge in sieve analysis isn't just shaking particles, but controlling their movement. Amplitude is the primary lever for controlling the energy of this movement, and finding the optimal setting is a critical trade-off between ensuring complete separation and preserving the original state of your particles.

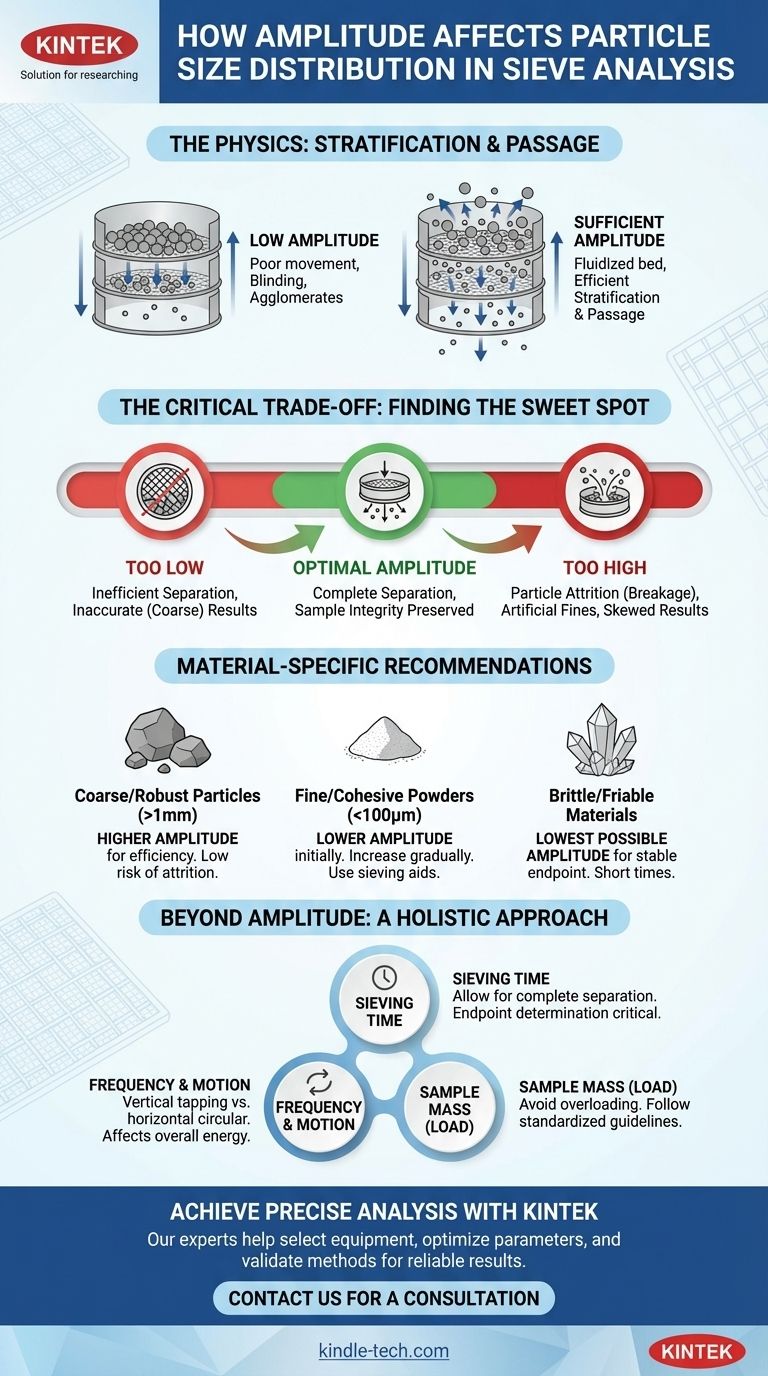

The Physics of Sieving: Why Amplitude Matters

To control a process, you must first understand its underlying mechanics. Sieve analysis relies on two fundamental actions: stratification and passage. Amplitude is the driving force behind both.

The Core Mechanism: Stratification and Passage

Sieving works by giving every particle a statistical opportunity to pass through an aperture. For this to happen, the bed of material on the sieve must first stratify, where smaller particles migrate downwards through the spaces between larger ones.

Once a particle reaches the sieve mesh, it must then be presented to an aperture in the correct orientation to pass through. Both of these actions require particle movement, which is induced by shaking.

The Role of Amplitude: Setting Particles in Motion

Amplitude is the magnitude of the displacement of the sieve during its shaking cycle. In a vertical tapping shaker, it's how high the sieve stack is lifted and dropped.

This movement imparts kinetic energy to the particles. A sufficient amplitude makes particles become airborne, momentarily separating them from each other and the sieve mesh. This "flight time" is essential for allowing the finer particles to fall beneath the coarser ones.

How Amplitude Drives Separation Efficiency

The level of amplitude directly dictates the efficiency of the separation process.

-

Insufficient Amplitude: Leads to poor results. Particles may not lift off the mesh at all, preventing stratification. This can cause blinding, where near-size particles get stuck in the apertures, or fail to break up agglomerates (clumps of fine particles). The result is an analysis that incorrectly shows the material as being coarser than it is.

-

Sufficient Amplitude: Provides enough energy to fluidize the particle bed. This ensures good stratification, keeps the mesh clear, and gives every particle multiple chances to be tested against an aperture, leading to an accurate and complete separation.

The Critical Trade-off: Efficiency vs. Particle Integrity

The goal is not maximum amplitude, but optimal amplitude. Pushing the energy level too high introduces significant and often unseen errors.

The Problem of Excessive Amplitude: Attrition

The most significant risk of high amplitude is particle attrition. When particles are thrown violently, they collide with each other and the hard surfaces of the sieve with high energy.

For brittle, crystalline, or friable materials, these impacts can cause particles to break, fracture, or wear down. This artificially generates fine particles that were not present in the original sample, skewing your distribution towards the smaller particle sizes and invalidating the analysis.

The Problem of Inefficient Sieving

Excessive amplitude can also paradoxically reduce efficiency. If the amplitude is so high that particles spend too much time in the air, they have fewer opportunities to contact the sieve mesh and pass through an opening. This can unnecessarily lengthen the required sieving time.

Finding the Optimal Amplitude "Sweet Spot"

The optimal amplitude is the minimum energy required to achieve complete separation within a reasonable timeframe without causing particle damage. This "sweet spot" is highly dependent on the material's characteristics, such as its density, size, and friability.

Beyond Amplitude: Other Critical Sieving Parameters

Achieving an accurate particle size analysis requires a holistic approach. Amplitude is a critical parameter, but it works in concert with others.

Sieving Time

Time is the second key factor. The process must run long enough for stratification and passage to reach their conclusion. A common method validation technique is to sieve in intervals, weighing the fractions each time until the mass on each sieve stabilizes (e.g., changes by <0.1%). This "endpoint determination" confirms your amplitude and time are sufficient.

Shaking Frequency and Motion

The type of motion (e.g., vertical tapping vs. horizontal circular) and its frequency also play a role. Frequency, combined with amplitude, determines the overall energy and helps dislodge particles stuck in the mesh.

Sample Mass (Sieve Loading)

Overloading a sieve is a primary source of error. If the bed of material is too deep, particles in the middle of the layer will never get a chance to reach the sieve mesh. Always follow standardized guidelines for the maximum sample mass based on your sieve diameter and material density.

How to Determine the Right Amplitude for Your Material

The ideal amplitude is not a universal constant; it must be determined empirically for your specific material and analysis goals.

- If your primary focus is analyzing coarse, robust particles (>1 mm): You can generally use a higher amplitude to ensure efficient separation, as the risk of attrition is low.

- If your primary focus is analyzing fine, cohesive powders (<100 µm): Start with a lower amplitude and gradually increase it, potentially using sieving aids, to break up agglomerates without causing damage to individual particles.

- If your primary focus is analyzing brittle or friable materials: Use the lowest possible amplitude that still achieves a stable endpoint, and keep sieving times as short as necessary to minimize particle breakage.

- If your primary focus is method validation and repeatability: Perform an endpoint determination test to systematically find the ideal combination of amplitude and time that produces a complete separation without changing the material.

Mastering amplitude is the key to transforming sieve analysis from a simple shaking process into a precise and repeatable analytical method.

Summary Table:

| Amplitude Level | Effect on Separation | Risk to Particles | Recommended Use Case |

|---|---|---|---|

| Too Low | Poor stratification, blinding, agglomerates remain | Minimal risk of breakage | Not recommended; leads to inaccurate coarse results |

| Optimal | Efficient stratification, clear mesh, complete separation | Minimal risk if correctly set | Ideal for most materials; ensures accuracy and preserves sample |

| Too High | Particles bounce excessively, reduced contact with mesh | High risk of attrition and breakage | Avoid; creates artificial fines and skews distribution |

Achieve precise and repeatable particle size analysis with KINTEK's advanced sieve shakers.

Struggling to find the perfect amplitude setting for your specific material? Our experts at KINTEK specialize in lab equipment and consumables, serving all your laboratory needs. We provide not only high-quality sieve shakers with precise amplitude control but also the technical support to validate your methods and ensure accurate results every time.

Let us help you:

- Select the right equipment for your material type (coarse, fine, brittle, or cohesive)

- Optimize your sieving parameters for maximum efficiency and sample integrity

- Validate your methods for repeatable, reliable particle size distribution data

Contact our team today for a consultation and see how KINTEK can enhance your sieve analysis workflow.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution