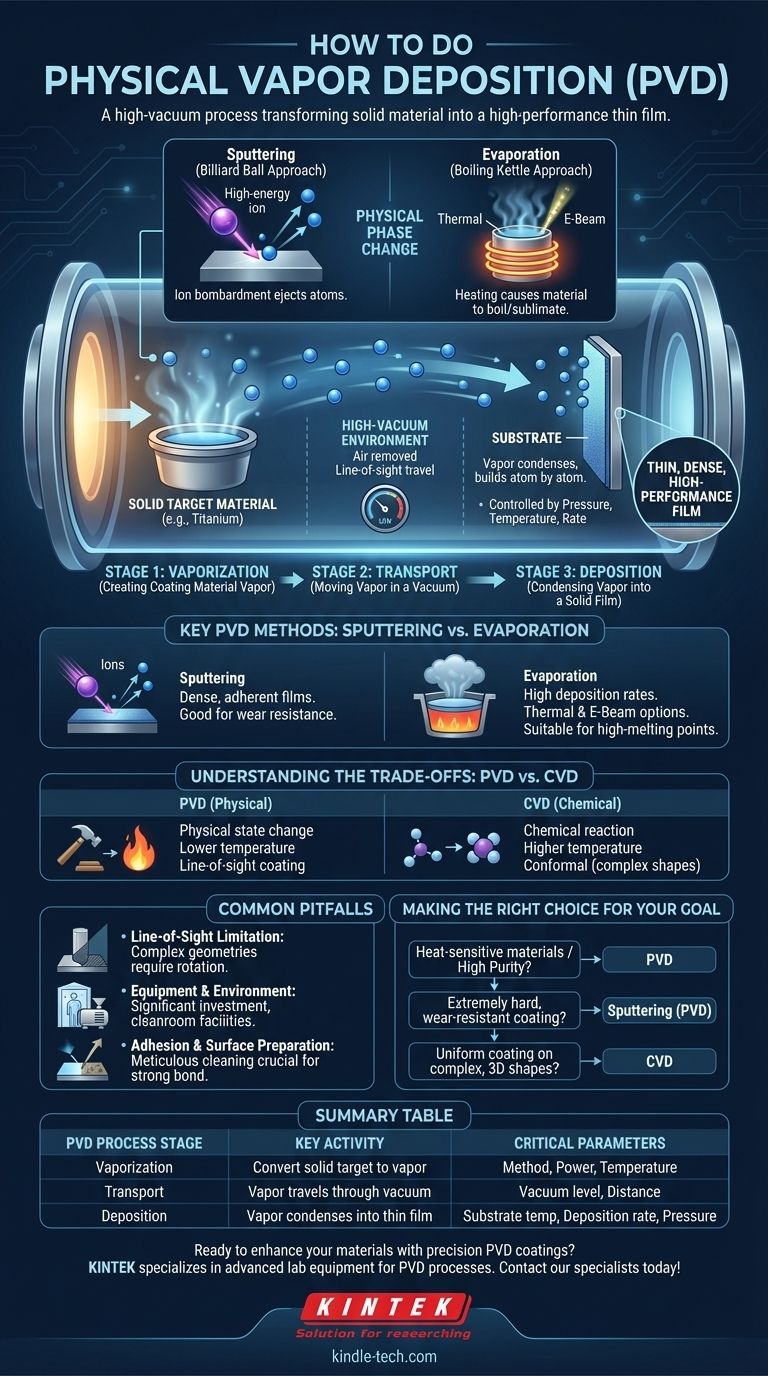

Performing physical vapor deposition (PVD) is a process that transforms a solid material into a vapor, which is then condensed onto a target object (the substrate) as a thin, high-performance film. This entire process is conducted within a high-vacuum chamber and can be broken down into three essential stages: vaporization of a source material, transport of the vapor, and deposition onto the substrate.

Physical Vapor Deposition is not one single technique but a family of vacuum-based processes. The core principle is always the same: a solid material is physically—not chemically—converted into a vapor that condenses as a high-performance coating onto a component.

The Universal PVD Process: A Three-Step Framework

While specific methods vary, every PVD process follows the same fundamental sequence inside a vacuum chamber. Understanding this framework is key to understanding how PVD works.

Step 1: Vaporization - Creating the Coating Material Vapor

The first step is to generate a vapor from a solid source material, known as the target. This target contains the material that will form the final coating, such as titanium, chromium, or aluminum.

This is a purely physical phase change, similar to boiling water into steam, but applied to metals and ceramics. The method used to create this vapor is the primary way different PVD techniques are categorized.

Step 2: Transport - Moving the Vapor in a Vacuum

Once created, the vaporized atoms or molecules travel from the target toward the substrate. This occurs within a high-vacuum environment.

The vacuum is critical for two reasons. First, it removes air and other particles that could contaminate the coating. Second, it ensures the vaporized atoms have a clear, unobstructed path to the substrate, a principle known as "line-of-sight" travel.

Step 3: Deposition - Condensing the Vapor into a Solid Film

When the vapor atoms strike the cooler surface of the substrate, they condense back into a solid state. They build up, atom by atom, to form a thin, dense, and highly adherent film.

The properties of the final coating—such as its hardness, density, and finish—are tightly controlled by managing process parameters like pressure, temperature, and deposition rate.

Key PVD Methods: Sputtering vs. Evaporation

The "how" of PVD truly lies in the method used for vaporization. The two most common families of PVD processes are sputtering and evaporation.

Sputtering: A Billiard Ball Approach

Sputtering is a process where atoms are physically ejected from the target material. Imagine a high-energy particle, typically an ion of an inert gas like argon, acting like a cue ball.

This ion is accelerated and shot at the target surface. The impact dislodges, or "sputters," atoms from the target, launching them toward the substrate where they form a coating. This method creates exceptionally dense and adherent films.

Evaporation: A Boiling Kettle Approach

Evaporation involves heating the source material until it boils or sublimates directly into a gas. This is most often done in two ways:

- Thermal Evaporation: The material is placed in a crucible and heated by electrical resistance until it evaporates.

- Electron-Beam Evaporation (E-Beam): A high-energy beam of electrons is fired at the source material, causing a localized spot to heat up intensely and vaporize. This allows for the deposition of materials with very high melting points, such as temperature-resistant ceramics used in aerospace.

Understanding the Trade-offs: PVD vs. CVD

It is crucial to distinguish PVD from its counterpart, Chemical Vapor Deposition (CVD), as they solve different problems.

The Core Distinction: Physical vs. Chemical

The fundamental difference is in how the vapor is created. PVD uses physical means (bombardment or heating) to change the state of the material.

Chemical Vapor Deposition (CVD), by contrast, introduces precursor gases into the chamber. These gases undergo a chemical reaction on the substrate surface, and a solid product of that reaction becomes the coating.

Temperature and Substrate Compatibility

PVD is generally a lower-temperature process than traditional CVD. This makes PVD suitable for coating materials that cannot withstand high heat, such as certain plastics or pre-hardened steels.

Coating Characteristics

Because PVD vapor travels in a straight line, it is excellent for coating flat surfaces or objects that can be easily rotated. CVD, however, excels at creating highly conformal coatings that uniformly cover complex, intricate 3D shapes.

Common Pitfalls and Considerations

Successfully implementing PVD requires sophisticated control and awareness of its inherent limitations.

The Line-of-Sight Limitation

In PVD, if a surface on the substrate cannot be "seen" from the vapor source, it will not be coated. This makes uniform coating of complex geometries challenging without complex fixtures to rotate parts during the process.

Equipment and Environment

PVD requires a significant investment in specialized equipment, including vacuum chambers, power supplies, and cooling systems. As the references note, these processes demand sophisticated equipment and cleanroom facilities to prevent contamination and ensure coating quality.

Adhesion and Surface Preparation

The final coating is only as good as its bond to the substrate. Successful deposition is impossible without meticulous cleaning and preparation of the substrate surface to remove any oils, oxides, or contaminants.

Making the Right Choice for Your Goal

Selecting the correct deposition technology depends entirely on the material you are coating and the performance you require.

- If your primary focus is coating heat-sensitive materials or achieving the highest purity: PVD is often the superior choice due to its lower process temperatures and physical nature.

- If your primary focus is creating an extremely hard, wear-resistant coating on a tool or simple component: Sputtering (a PVD method) provides a dense, durable film with excellent adhesion.

- If your primary focus is uniformly coating a complex, 3D object like an internal passage: Chemical Vapor Deposition (CVD) is generally better suited for creating conformal coatings.

Understanding these core principles is the first step toward leveraging vapor deposition to create high-performance materials.

Summary Table:

| PVD Process Stage | Key Activity | Critical Parameters |

|---|---|---|

| Vaporization | Convert solid target material to vapor | Method (sputtering/evaporation), power, temperature |

| Transport | Vapor travels through vacuum chamber | Vacuum level, distance to substrate |

| Deposition | Vapor condenses into thin film on substrate | Substrate temperature, deposition rate, pressure |

Ready to enhance your materials with precision PVD coatings? KINTEK specializes in advanced lab equipment and consumables for physical vapor deposition processes. Our expertise helps laboratories achieve superior thin film results with excellent adhesion and purity. Contact our PVD specialists today to discuss how our solutions can optimize your coating applications!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is the process of chemical vapour deposition? A Guide to High-Quality Thin Film Coating

- What are the steps involved in CVD? Master the 6 Stages of Thin Film Deposition

- How does CVD work? A Step-by-Step Guide to Chemical Vapor Deposition

- What are the techniques for graphene growth? A Guide to Top-Down and Bottom-Up Methods

- What is thin film deposition by magnetron sputtering? A Guide to High-Precision Coating

- What is the process of chemical Vapour deposition CVD? A Step-by-Step Guide to High-Purity Film Growth

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the application of protective coating? Enhance Durability and Aesthetics for Your Products