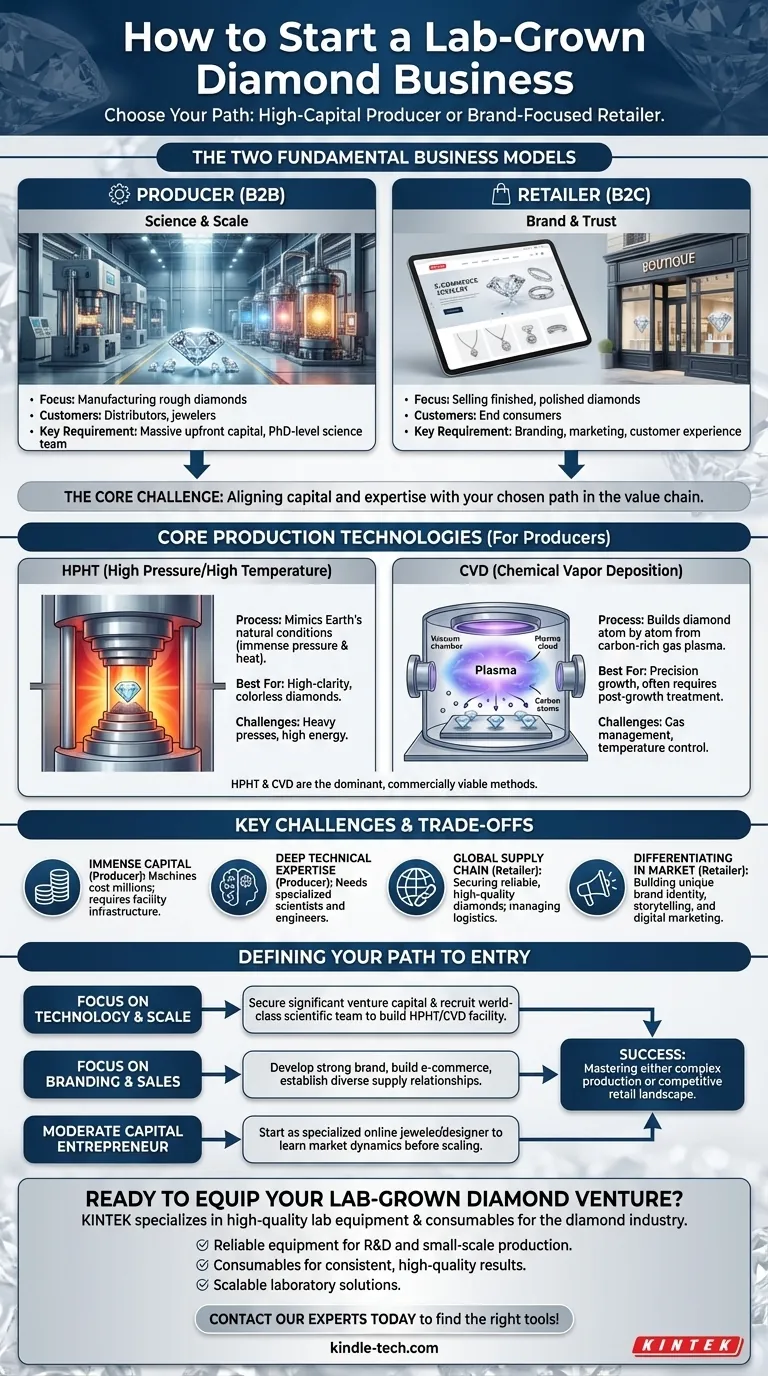

To start a lab-grown diamond business, you must first decide on a fundamental business model: becoming a high-capital producer who physically creates diamonds, or a brand-focused retailer who markets and sells them. The production path requires immense investment in complex technologies like High Pressure/High Temperature (HPHT) or Chemical Vapor Deposition (CVD), while the retail path demands expertise in branding, marketing, and supply chain management.

The core challenge is not simply making a diamond, but choosing where to position yourself in the value chain. Success hinges on aligning your capital, technical expertise, and market strategy with either the complex science of production or the competitive art of retail.

The Two Fundamental Business Models

Every lab-grown diamond business falls into one of two primary categories. Your choice here is the single most important decision you will make, as it dictates your investment, team, and daily operations.

The Producer: A Game of Science and Scale

This is a capital-intensive, B2B business focused on manufacturing rough lab-grown diamonds. You are essentially a high-tech factory selling your product to distributors, cutters, and jewelry brands.

Success requires massive upfront investment in specialized equipment and deep scientific knowledge. Your customers are businesses, not the general public.

The Retailer: A Game of Brand and Trust

This is a brand-intensive, B2C business focused on selling finished, polished diamonds to consumers. You source stones from various producers and build a brand that resonates with a target market.

Your focus is on marketing, e-commerce, customer experience, and design. You are competing for the end consumer's trust and wallet.

The Core Production Technologies

If you choose the producer path, your next critical decision is the technology you will use. Each method has distinct operational and financial implications.

High Pressure/High Temperature (HPHT)

HPHT mimics the natural diamond-growing process of the Earth. A small diamond "seed" is placed in a chamber with pure carbon and subjected to immense pressure and heat, causing the carbon to crystallize around the seed.

This method requires massive, heavy presses and enormous energy consumption. It is well-established and particularly effective for creating high-clarity, colorless diamonds.

Chemical Vapor Deposition (CVD)

CVD builds a diamond from the ground up, atom by atom. A diamond seed is placed in a vacuum chamber filled with carbon-rich gases, which are then ionized into a plasma, causing carbon atoms to deposit onto the seed and grow a diamond.

This technology generally requires less extreme pressure than HPHT but demands incredible precision in managing gases, temperature, and chemistry. Many CVD diamonds require post-growth treatment to improve their color.

Niche & Emerging Methods

Other methods exist, such as the detonation of explosives or ultrasound cavitation. However, HPHT and CVD are the two dominant and commercially viable technologies for producing gem-quality diamonds today.

Understanding the Trade-offs and Challenges

Entering this industry requires a clear understanding of the significant hurdles you will face, whether you are a producer or a retailer.

The Challenge of Immense Capital

For producers, the cost of a single HPHT press or CVD reactor can run into the hundreds of thousands or even millions of dollars. A viable production facility requires a fleet of these machines, plus the infrastructure to support them.

The Need for Deep Technical Expertise

Diamond production is not a simple manufacturing process. It requires PhD-level material scientists, physicists, and engineers to operate, maintain, and optimize the equipment. This talent is scarce and expensive.

Navigating a Global Supply Chain

Retailers must secure a consistent and reliable supply of high-quality diamonds. This means building relationships with producers around the world, understanding the grading process, and managing the logistics of cutting, polishing, and setting.

Differentiating in a Crowded Market

The lab-grown market is increasingly competitive. For retailers, success depends entirely on your ability to build a unique brand identity, tell a compelling story (e.g., sustainability, value), and master digital marketing to reach your customers.

Defining Your Path to Entry

Your strategy must be dictated by your resources, expertise, and ultimate business goal.

- If your primary focus is on technology and large-scale manufacturing: Your first step is to secure significant venture capital and begin recruiting a world-class scientific team to build out an HPHT or CVD production facility.

- If your primary focus is on branding and consumer sales: Concentrate on developing a strong brand identity, building a best-in-class e-commerce platform, and establishing relationships with multiple diamond producers to ensure a diverse supply.

- If you are an entrepreneur with moderate capital: The most viable entry point is retail. Start as a specialized online jeweler or designer, allowing you to learn the market dynamics and build a brand before considering the enormous leap into production.

Ultimately, your success will be determined by a clear and unwavering focus on mastering either the complex world of production or the competitive landscape of modern retail.

Summary Table:

| Business Model | Primary Focus | Key Challenge | Ideal For |

|---|---|---|---|

| Producer (B2B) | Manufacturing diamonds using HPHT/CVD | Immense capital investment & technical expertise | Entrepreneurs with deep scientific resources and significant funding |

| Retailer (B2C) | Branding, marketing, and selling finished diamonds | Differentiation in a crowded market & supply chain management | Brand-focused entrepreneurs with marketing skills |

Ready to Equip Your Lab-Grown Diamond Venture?

Whether you're launching a production facility or a retail brand, having the right equipment is foundational to your success. KINTEK specializes in providing high-quality lab equipment and consumables tailored to the precise needs of the diamond industry.

We support businesses like yours by:

- Supplying reliable equipment for R&D and small-scale production.

- Ensuring you have the consumables needed for consistent, high-quality results.

- Helping you scale efficiently with trusted laboratory solutions.

Let's discuss your specific needs. Contact our experts today to find the right tools for your lab-grown diamond business!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- CVD Diamond for Thermal Management Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are nanotubes drawbacks? The 4 Major Hurdles Limiting Their Real-World Use

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition