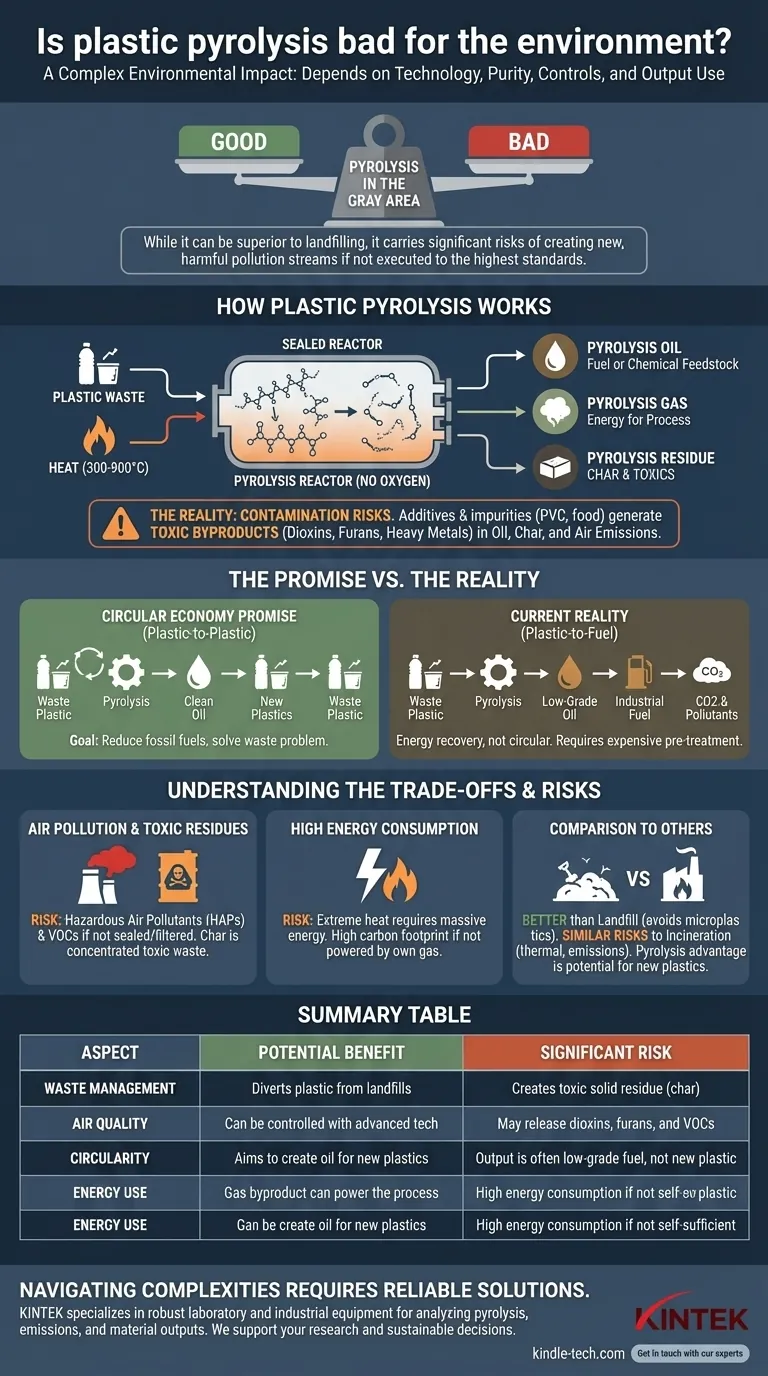

The environmental impact of plastic pyrolysis is highly complex and not inherently "good" or "bad." Its effect depends almost entirely on the specific technology used, the purity of the plastic waste being processed, the stringency of operational controls, and how the outputs are ultimately used. While it can be a superior alternative to landfilling, it carries significant risks of creating new, harmful pollution streams if not executed to the highest standards.

The central challenge is that plastic pyrolysis exists in a gray area between a genuine recycling solution and a form of waste-to-pollution. Its promise of creating a circular economy is often undermined by the technical difficulty and high energy cost of converting mixed, contaminated plastic waste into a product clean enough to make new plastics.

How Plastic Pyrolysis Works (And Where It Fails)

Plastic pyrolysis is a form of thermal decomposition, meaning it uses high heat to break down materials. The key is that this occurs in the absence of oxygen.

The Core Chemical Process

Pyrolysis heats plastic waste to very high temperatures (typically 300-900°C) in a sealed, oxygen-free reactor. Instead of burning, the long polymer chains that make up plastic break down into smaller, simpler molecules, forming a liquid and a gas.

The Intended Outputs

This process primarily creates three products:

- Pyrolysis Oil: An oil-like liquid (also called "py-oil" or "taco-oil") that can be refined and used as fuel or, in theory, as a feedstock to make new chemicals and plastics.

- Pyrolysis Gas: A mix of combustible gases (like hydrogen, methane, and ethylene) that is typically used to power the pyrolysis facility itself, reducing external energy needs.

- Pyrolysis Residue: A solid, carbon-rich byproduct often called char.

The Unintended and Problematic Byproducts

Real-world plastic waste is rarely pure. It contains additives, dyes, flame retardants, and contaminants like food residue, paper labels, and different plastic types (like PVC). This contamination creates significant environmental hazards.

When heated, these contaminants can generate highly toxic substances, including dioxins, furans, and heavy metals (like lead and cadmium), which can end up in the oil, the char, or released as air emissions if the system has leaks or inadequate controls. Moisture in the waste also generates contaminated wastewater.

Assessing the Claims vs. The Reality

Pyrolysis is often marketed as "advanced recycling" or a key to the "circular economy." The reality is more nuanced.

The "Circular Economy" Promise

The ideal vision for pyrolysis is a closed loop: waste plastic is converted into high-quality oil, which is then used to manufacture new, identical plastics. This would reduce the need for virgin fossil fuels and solve the plastic waste problem.

The Reality: From Plastic-to-Fuel

Currently, the vast majority of pyrolysis oil is not clean enough to be made back into plastic without significant, energy-intensive, and expensive pre-treatment. Most of it is instead burned as a low-grade fuel in industrial furnaces or boilers.

While this recovers energy, it is not a circular process. It is a one-time conversion of plastic to fuel, which still releases CO2 and other pollutants when combusted.

Understanding the Trade-offs and Risks

Evaluating pyrolysis requires comparing it not to a perfect world, but to the other primary options: landfills and incineration.

Air Pollution and Toxic Residues

This is the most significant environmental risk. If a facility is not perfectly sealed and equipped with advanced pollution control systems, it can release hazardous air pollutants (HAPs) and volatile organic compounds (VOCs).

Furthermore, the solid char residue can be a concentrated toxic waste. It often contains the heavy metals, chlorine, and other contaminants from the original plastic, requiring careful disposal in a specialized hazardous waste landfill.

High Energy Consumption

The pyrolysis process is energy-intensive. Heating hundreds of tons of plastic to extreme temperatures requires a massive energy input. If this energy comes from fossil fuels rather than the facility's own pyrolysis gas, the net carbon footprint of the operation can be substantial.

Comparison to Landfills and Incineration

Compared to a landfill, pyrolysis is generally a better option for preventing plastic from slowly breaking down into microplastics and leaching chemicals into the ground.

Compared to modern, highly regulated incineration (Waste-to-Energy), the picture is less clear. Both are thermal processes that can create toxic emissions if not controlled, and both can recover energy. The key differentiator is whether the pyrolysis output can truly be used to make new plastics, which remains a major challenge.

Making the Right Choice for the Goal

Pyrolysis is not a silver bullet for the plastic crisis. Its value depends entirely on the standards to which it is held.

- If your primary focus is diverting plastic from landfills at all costs: Pyrolysis can be a functional tool for volume reduction and energy recovery, but it must have strict emissions controls.

- If your primary focus is a truly circular economy for plastics: You must be skeptical of current pyrolysis claims, as turning its low-quality oil back into new plastic is still more of an ambition than a widespread reality.

- If your primary concern is preventing all forms of pollution: You must demand proof of a facility's advanced air pollution controls, its plan for managing toxic char, and the net energy balance of its operation.

Ultimately, plastic pyrolysis is a transitional technology that holds potential but requires rigorous regulation and technological advancement to avoid simply transforming a solid waste problem into a hazardous air and land pollution problem.

Summary Table:

| Aspect | Potential Benefit | Significant Risk |

|---|---|---|

| Waste Management | Diverts plastic from landfills | Creates toxic solid residue (char) |

| Air Quality | Can be controlled with advanced tech | May release dioxins, furans, and VOCs |

| Circularity | Aims to create oil for new plastics | Output is often low-grade fuel, not new plastic |

| Energy Use | Gas byproduct can power the process | High energy consumption if not self-sufficient |

Navigating the complexities of waste management requires reliable, high-performance equipment. KINTEK specializes in providing robust laboratory and industrial solutions for analyzing pyrolysis processes, emissions, and material outputs. Whether you're researching advanced recycling technologies or need precise monitoring equipment, our expertise ensures you have the right tools to make informed, sustainable decisions. Contact us today to discuss how we can support your environmental and recycling goals. Get in touch with our experts

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What is material deposition in manufacturing? Unlock Design Freedom with Additive Processes

- What is the difference between PVD and CVD? Choose the Right Thin-Film Deposition Technique

- How thick is a sputtering target? A Guide to Specifying the Right Thickness for Your Process

- What is the CVD process in semiconductors? A Guide to Building Microchips from Gas

- What gases are used in chemical vapor deposition? Choosing the Right Precursors for Your Thin Film

- What is the temperature range for LPCVD? A Guide to Process Parameters by Material

- Why is the removal of byproducts crucial in a CVD process? Ensure Film Purity and High Semiconductor Yields

- What are the steps in the CVD method? A Guide to Thin Film Deposition