Yes, a PVD coating can be brilliantly shiny, but the coating itself does not create the shine. The final appearance of a PVD-coated item is determined entirely by the surface finish of the underlying material. To achieve a polished, mirror-like PVD finish, the part must be polished to a mirror shine before the coating process begins.

The essential takeaway is that a PVD coating is a thin, conformal layer that perfectly mimics the texture of the substrate it covers. The shine, satin, or matte appearance you see is not from the PVD itself, but a direct reflection of the surface preparation done beforehand.

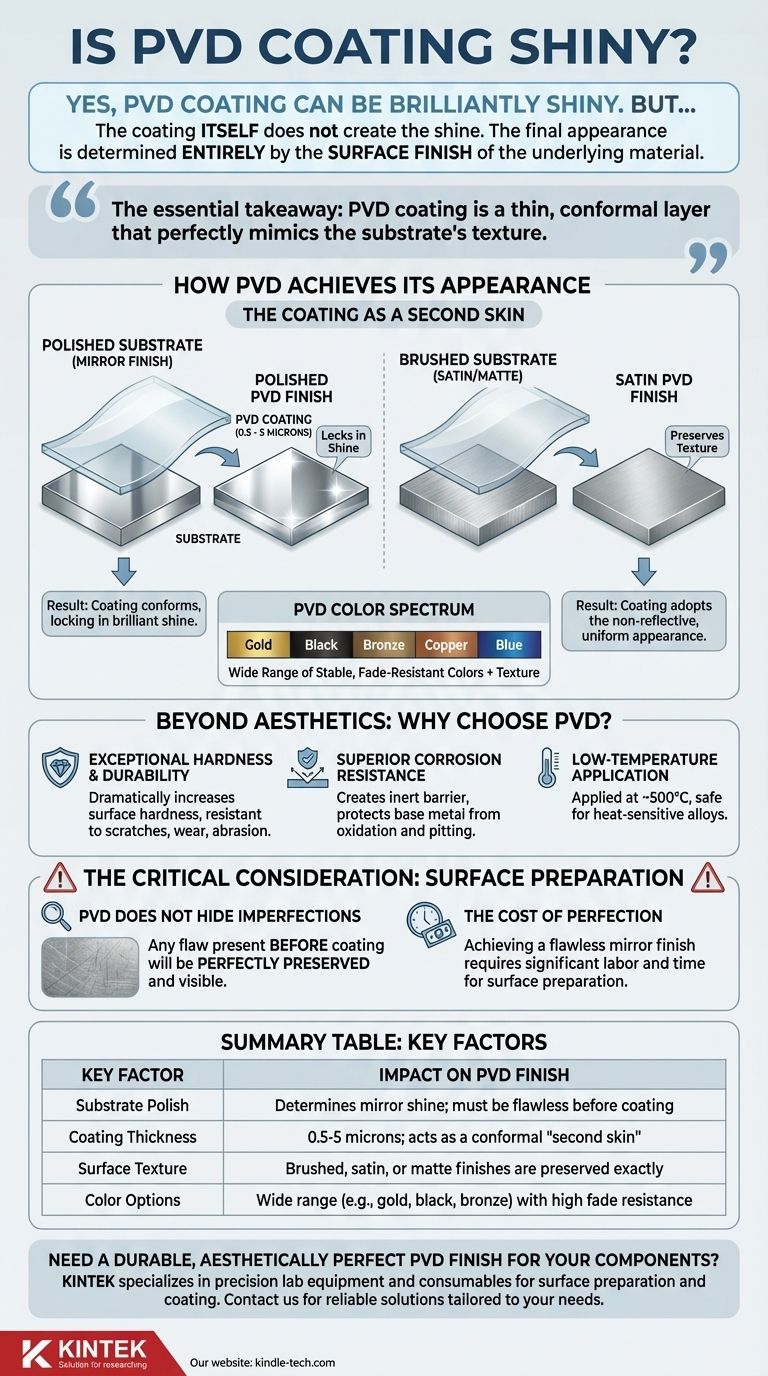

How PVD Achieves Its Final Appearance

Physical Vapor Deposition (PVD) is a sophisticated process that bonds a very thin layer of material to a substrate on a molecular level. Understanding how this thinness impacts the final look is key.

The Coating as a Second Skin

A PVD coating is exceptionally thin, typically ranging from just 0.5 to 5 microns. Think of it not as a thick layer of paint that covers things up, but as a transparent film that conforms to every microscopic detail of the surface beneath it.

This process preserves the original surface texture with perfect fidelity. It does not level, fill, or hide any imperfections.

The Substrate Dictates the Texture

Because the PVD layer is so thin and conformal, the final aesthetic is a direct result of the base material's preparation.

- For a polished or mirror finish: The substrate must be buffed and polished to a flawless, mirror-like state before entering the PVD chamber. The coating will then lock in and protect that brilliant shine.

- For a satin or matte finish: The substrate must be given a brushed, satin, or bead-blasted texture. The PVD coating will then adopt this non-reflective, uniform appearance.

A Spectrum of Colors and Effects

Beyond just texture, PVD offers a wide range of vibrant color choices. These colors are highly stable and resistant to fading, discoloration, and corrosion, even in harsh environments like coastal areas. This allows you to combine a specific texture (like satin) with a specific color (like gold, black, or bronze) for a unique decorative finish.

Beyond Aesthetics: Why Choose PVD?

While the visual finish is important, the decision to use PVD is usually driven by its significant functional benefits. The aesthetic quality is a feature that accompanies superior performance.

Exceptional Hardness and Durability

PVD coatings dramatically increase the surface hardness of the substrate. This creates a finish that is highly resistant to scratches, wear, and abrasion, making it ideal for high-contact items like tools, fixtures, and jewelry.

Superior Corrosion Resistance

The coating creates an inert barrier that protects the base metal from oxidation, corrosion, and pitting. This is a primary reason PVD is used for architectural hardware, marine components, and medical devices.

Low-Temperature Application

PVD is a low-temperature process (around 500°C), which means it can be safely applied to a wider variety of materials, including some heat-sensitive alloys, without risking thermal damage or warping.

The Critical Consideration: Surface Preparation

The single most common mistake when specifying a PVD finish is misunderstanding the role of surface preparation.

PVD Does Not Hide Imperfections

Unlike thicker processes like electroplating or painting, PVD will not fill scratches, smooth out tool marks, or hide any other surface defects. In fact, it can make them more noticeable.

Any flaw present on the part before it is coated will be perfectly preserved and visible on the final product. The principle is "what you see is what you get."

The Cost of Perfection

Achieving a flawless mirror PVD finish requires significant labor to prepare the substrate. The cost and time associated with polishing the base part to perfection is often the most demanding aspect of the entire process.

How to Specify Your PVD Finish

To get the result you want, your focus must be on the substrate preparation.

- If your primary focus is a mirror-like shine: Your substrate must be polished to a flawless, defect-free mirror finish before the PVD process.

- If your primary focus is a satin or matte look: Use a directional brushed finish or a non-directional bead-blasted surface to achieve the desired texture on the substrate first.

- If your primary focus is durability above all: PVD is an excellent choice, but ensure the surface is prepared to the aesthetic standard you require, as that look will be permanently locked in.

Ultimately, achieving the perfect PVD finish begins not with the coating process itself, but with the meticulous preparation of the surface beneath it.

Summary Table:

| Key Factor | Impact on PVD Finish |

|---|---|

| Substrate Polish | Determines mirror shine; must be flawless before coating |

| Coating Thickness | 0.5-5 microns; acts as a conformal 'second skin' |

| Surface Texture | Brushed, satin, or matte finishes are preserved exactly |

| Color Options | Wide range (e.g., gold, black, bronze) with high fade resistance |

Need a Durable, Aesthetically Perfect PVD Finish for Your Components?

KINTEK specializes in precision lab equipment and consumables, including solutions for surface preparation and coating processes. Whether you're in jewelry, medical devices, or architectural hardware, our expertise ensures your substrates are prepared to the highest standards for a flawless PVD result.

Contact us today to discuss how we can support your project with reliable equipment and consumables tailored to your laboratory's needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating