In almost all cases, no. Quenching, or rapid cooling, is fundamentally the opposite of the slow cooling process that defines traditional annealing. The primary goal of annealing is to soften a metal, increase its ductility, and relieve internal stresses. The primary goal of quenching, by contrast, is to trap the metal in a very hard and brittle state. The confusion arises because a few specialized processes, such as "quench annealing" for specific alloys, exist, but they are exceptions to the rule.

The defining characteristic of a heat treatment is its intended outcome, which dictates the cooling rate. Standard annealing always uses a slow cool to achieve softness, while hardening processes use a rapid quench to achieve hardness. Conflating the two is the most common point of confusion.

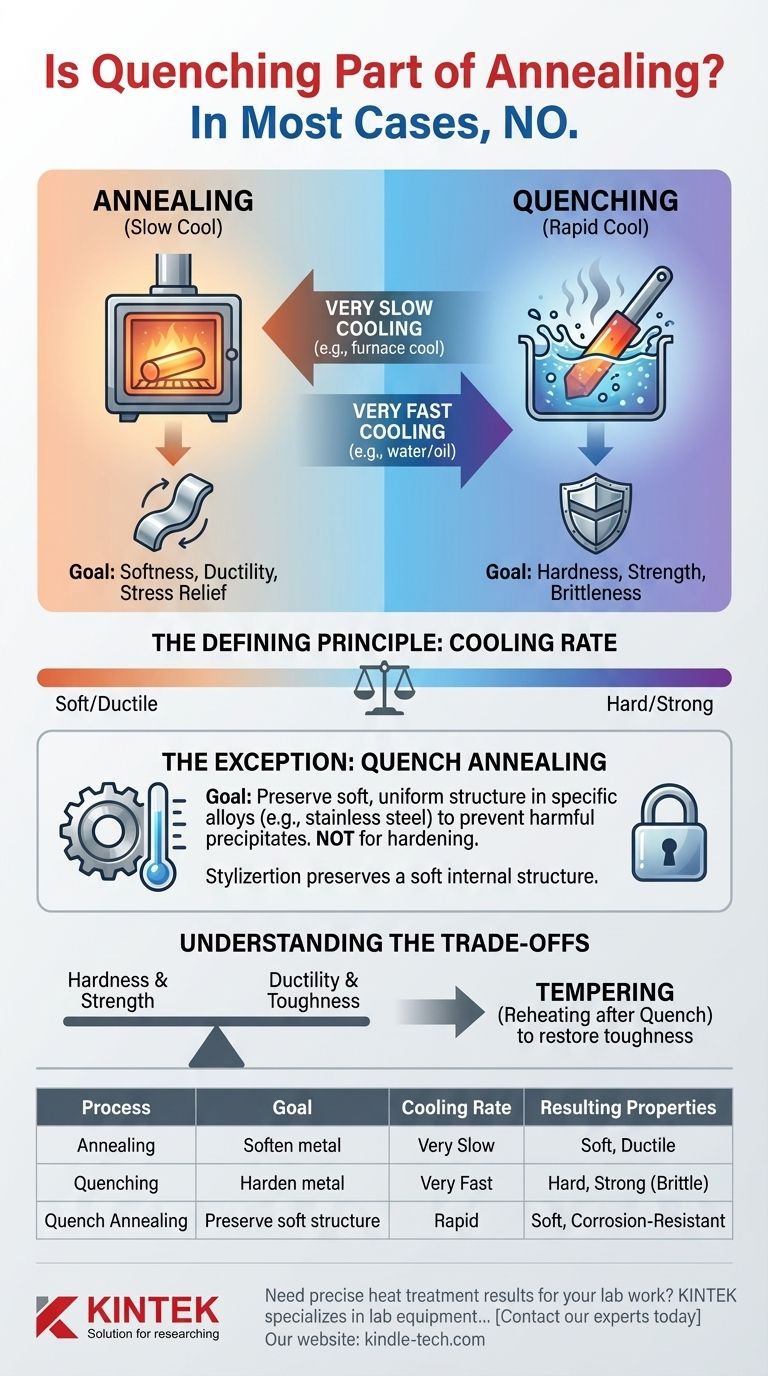

The Defining Principle: Cooling Rate and Its Purpose

The critical difference between annealing and hardening lies in how the metal is cooled after being heated. This cooling rate directly manipulates the final microscopic structure of the steel, which in turn determines its mechanical properties like hardness and ductility.

The Goal of Annealing: Softness and Stress Relief

Annealing involves heating a metal above its critical recrystallization temperature and then cooling it very slowly, often by leaving it inside the turned-off furnace.

This slow cooling allows the metal's crystal structure (its grains) to reform in a highly orderly, uniform, and low-energy state. Think of it like letting a shaken snow globe settle slowly and perfectly.

The result is a metal that is significantly softer, more ductile (easier to bend or form), and free from the internal stresses that can cause cracking or warping. This is ideal for preparing a part for further machining or cold working.

The Goal of Quenching: Hardness and Strength

Quenching is the core of the hardening process, not annealing. After heating, the metal is plunged into a medium like water, oil, or air to cool it as rapidly as possible.

This rapid cooling does not give the crystal structure time to settle into an orderly state. Instead, it traps the high-temperature structure (austenite) and forces it into a highly strained, distorted, and hard structure called martensite.

The result is a metal that is extremely hard and strong but also very brittle. This high hardness provides excellent wear resistance.

The Exception: Deconstructing "Quench Annealing"

The term "quench annealing" is a primary source of this confusion, as it appears to combine two opposing concepts. However, its purpose is entirely different from a hardening quench.

What is Quench Annealing?

This is a specialized process used for certain alloys, most notably austenitic stainless steels (like 304 or 316) and some aluminum alloys.

In this context, the goal is still to produce a soft, uniform structure. However, a slow cool would cause undesirable elements (like chromium carbides in stainless steel) to precipitate at the grain boundaries, which can reduce corrosion resistance.

Therefore, the material is quenched to cool it rapidly through this problematic temperature range, effectively "locking in" the desirable soft, annealed structure from the high temperature. The quench prevents the formation of harmful precipitates.

Why the Name is Confusing

The key distinction is the end goal. In quench annealing, the quench is a tool used to preserve the soft, annealed state. In hardening, the quench is a tool used to create a new, hard martensitic state. The action is similar, but the metallurgical purpose is opposite.

Understanding the Trade-offs: Hardness vs. Ductility

In metallurgy, you can rarely get something for nothing. The properties of hardness and ductility exist on a spectrum, and heat treatment is the primary way to move a material along it.

The Fundamental Exchange

Processes that increase hardness, like quenching, almost always decrease ductility and toughness, making the material more brittle.

Conversely, processes that increase ductility and relieve stress, like full annealing, will always reduce the material's hardness and strength.

The Role of Tempering

A part that has been quenched for hardening is almost never used in its as-quenched state because it is too brittle. It would be like trying to use a tool made of glass.

This is why hardening is almost always a two-step process: hardening (quench) followed by tempering. Tempering involves reheating the quenched part to a much lower temperature to relieve some of the internal stress, trading a small amount of hardness for a significant gain in toughness.

Making the Right Choice for Your Goal

Your choice of heat treatment must be dictated by the final properties your component requires.

- If your primary focus is to soften metal for easier machining or forming: You need a traditional annealing process defined by its slow, controlled cooling rate.

- If your primary focus is to achieve maximum surface hardness and wear resistance: You need a hardening process that uses quenching, which must then be followed by tempering to restore toughness.

- If you are working with specific alloys like austenitic stainless steel: You may use "quench annealing," where a rapid cool is used to preserve a soft, corrosion-resistant structure, not to harden it.

Ultimately, understanding the intended outcome—softness and ductility versus hardness and strength—is the key to deciphering any heat treatment process.

Summary Table:

| Process | Goal | Cooling Rate | Resulting Properties |

|---|---|---|---|

| Annealing | Soften metal, relieve stress, increase ductility | Very Slow (e.g., furnace cool) | Soft, Ductile, Machinable |

| Quenching | Harden metal, increase strength | Very Fast (e.g., water/oil quench) | Hard, Strong, Brittle (requires tempering) |

| Quench Annealing | Preserve soft structure in specific alloys (e.g., stainless steel) | Rapid (to prevent precipitation) | Soft, Corrosion-Resistant |

Need precise heat treatment results for your lab work? KINTEK specializes in lab equipment and consumables, including furnaces designed for accurate annealing, quenching, and tempering processes. Our expertise ensures you achieve the exact material properties—whether softness for machining or hardness for wear resistance—your research demands. Contact our experts today to discuss your specific laboratory needs and discover the right equipment for your applications.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the normal temperature for a furnace? Unlock the Key to Efficient Home Heating

- How does a high-temperature annealing furnace facilitate the homogenization of high-entropy alloys and stainless steels?

- What is the difference between liquid and gas carburizing? Precision, Safety & Environmental Impact

- Why is a non-consumable tungsten electrode used in vacuum arc furnaces? Ensuring Purity in Ti-Cr-Al-V Alloys

- What is the function of calciner? Unlock Material Transformation for Your Industry

- What's the difference between brazing and braze welding? Mastering Joint Strength & Application

- What are the advantages of brazing? Achieve Superior Joint Integrity for Complex Assemblies

- What is the temperature range for brazing? Master the Critical Heat for Strong Joints