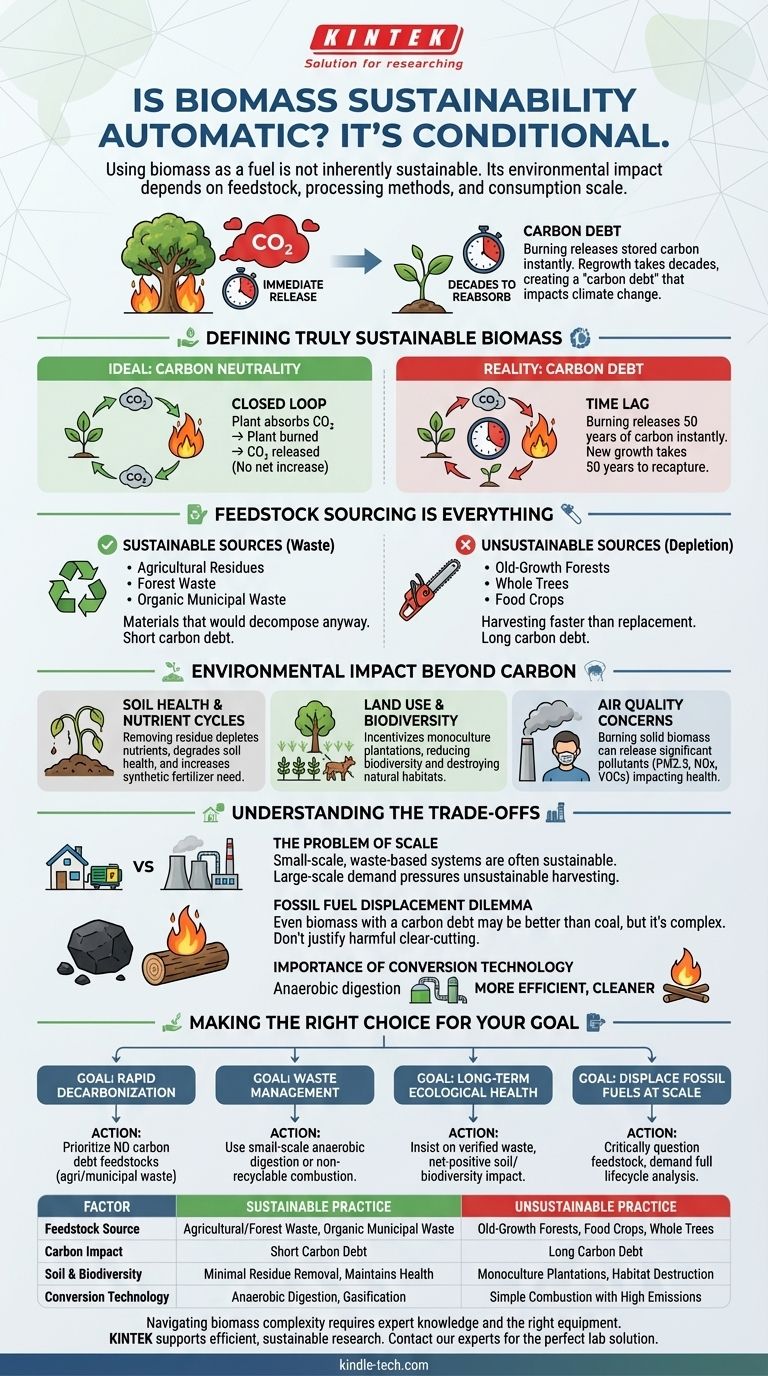

The sustainability of biomass is not a given; it is a conditional outcome. While often categorized as a renewable energy source, using biomass as a fuel is not inherently or automatically sustainable. Its true environmental impact hinges entirely on the type of biomass used, the methods of harvesting and processing, and the scale of its consumption.

The central challenge of biomass sustainability is the concept of "carbon debt." While biomass can be carbon-neutral in theory, burning it releases carbon immediately, creating a debt that is only "repaid" over the time it takes for new biomass to grow and reabsorb that same amount of carbon.

What Defines Truly Sustainable Biomass?

To determine if a biomass source is sustainable, we must look beyond simple labels and analyze the entire lifecycle, from growth to energy conversion.

The Ideal of Carbon Neutrality

The core argument for biomass is that it is part of a closed carbon loop. A plant absorbs atmospheric CO₂ as it grows, and when that plant is burned for energy, it releases the same amount of CO₂ back into the atmosphere. In a perfectly balanced system, this results in no net increase in atmospheric carbon.

The Reality of the "Carbon Debt"

This ideal cycle breaks down when considering time. Burning a 50-year-old tree for energy releases 50 years' worth of stored carbon instantly. It will take a new tree 50 years to grow and recapture that same amount of carbon. During that half-century, that extra CO₂ contributes to climate change. This time lag is known as the carbon debt.

Feedstock Sourcing is Everything

The sustainability of biomass is determined almost entirely by its source material, or feedstock.

-

Sustainable sources typically include waste products with no other economic use. Examples are agricultural residues (like corn stalks or wheat straw), sustainably harvested forest waste (like branches and treetops left after logging), and organic municipal waste. These materials would decompose and release carbon anyway.

-

Unsustainable sources involve harvesting that depletes a resource faster than it can be replaced. This includes clearing old-growth or primary forests, using whole trees that could serve as long-term carbon stores in wood products, and diverting food crops (like corn or sugarcane) which creates competition for land and food resources.

The Environmental Impact Beyond Carbon

A narrow focus on carbon can obscure other significant environmental impacts that must be considered.

Soil Health and Nutrient Cycles

Constantly removing all plant residue from fields or forests for fuel also removes critical nutrients and organic matter. This can degrade soil health over time, reduce its ability to hold water, and increase the need for synthetic fertilizers, which have their own significant environmental footprint.

Land Use and Biodiversity

When demand for biomass grows, it can incentivize the conversion of natural ecosystems, like forests or grasslands, into monoculture plantations of "energy crops." This drastically reduces biodiversity and destroys natural habitats.

Air Quality Concerns

Burning solid biomass, especially in smaller or less-advanced facilities, can release significant amounts of air pollutants. These include particulate matter (PM2.5), nitrogen oxides (NOx), and volatile organic compounds (VOCs), which have direct impacts on human health.

Understanding the Trade-offs

Declaring biomass as simply "good" or "bad" is a mistake. Its utility is context-dependent, and understanding the trade-offs is essential for making sound decisions.

The Problem of Scale

Small-scale, local biomass systems that use available waste are often highly sustainable and beneficial. However, large, utility-scale power plants require enormous, consistent feedstock supplies, which can create intense pressure to harvest biomass unsustainably.

The "Fossil Fuel Displacement" Dilemma

Proponents often argue that even biomass with a carbon debt is better than burning fossil fuels like coal. This is a complex calculation. While it may be true in some cases, it can also create a false justification for practices like clear-cutting forests, where the long-term ecological damage and carbon debt may be worse than alternative clean energy solutions.

The Importance of Conversion Technology

Simply burning biomass is the least efficient way to use it. Advanced technologies like anaerobic digestion (which creates biogas and a nutrient-rich digestate) or gasification can be far more efficient and produce fewer air pollutants, representing a more sustainable pathway.

Making the Right Choice for Your Goal

To properly evaluate a biomass project, you must first define your primary objective.

- If your primary focus is rapid decarbonization: Prioritize feedstocks with no carbon debt, such as agricultural waste, municipal waste, or byproducts from existing industries.

- If your primary focus is waste management: Small-scale anaerobic digestion or combustion of non-recyclable organic waste can be an excellent way to generate local energy and reduce landfill burdens.

- If your primary focus is long-term ecological health: Insist on projects that use only verified waste streams and demonstrate a net-neutral or net-positive impact on soil health, biodiversity, and air quality.

- If your primary focus is displacing fossil fuels at scale: Critically question the source of the feedstock and demand a full lifecycle analysis that accounts for the carbon debt and land-use impacts.

By moving beyond simple labels and asking critical questions about the source, scale, and system, you can effectively distinguish truly renewable energy from a solution that merely shifts the environmental burden.

Summary Table:

| Factor | Sustainable Practice | Unsustainable Practice |

|---|---|---|

| Feedstock Source | Agricultural residues, forest waste, organic municipal waste | Old-growth forests, food crops, whole trees for fuel |

| Carbon Impact | Short carbon debt (waste streams) | Long carbon debt (slow-growing trees) |

| Soil & Biodiversity | Minimal residue removal, maintains soil health | Monoculture plantations, habitat destruction |

| Conversion Technology | Anaerobic digestion, gasification | Simple combustion with high emissions |

Ready to make truly sustainable energy choices for your laboratory?

Navigating the complexities of biomass and other energy sources requires expert knowledge and the right equipment. KINTEK specializes in providing advanced lab equipment and consumables that support efficient, sustainable research and energy conversion processes—from anaerobic digestion studies to precise environmental impact analysis.

Let us help you achieve your sustainability and efficiency goals. Contact our experts today to find the perfect solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What is the primary function of a laboratory autoclave in the pre-treatment of medical plastic waste for liquid fuel?

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing