At their core, electric arc furnaces (EAFs) are primarily used to produce new carbon and alloy steels by melting recycled ferrous scrap. They are a cornerstone of modern metal recycling, using immense electrical energy to transform scrap metal into high-quality liquid steel ready for manufacturing.

The essential role of an electric arc furnace is to act as a powerful recycling engine for the steel industry. It uses a high-energy electric arc to efficiently melt down scrap steel, providing a flexible and more sustainable alternative to producing steel from raw iron ore.

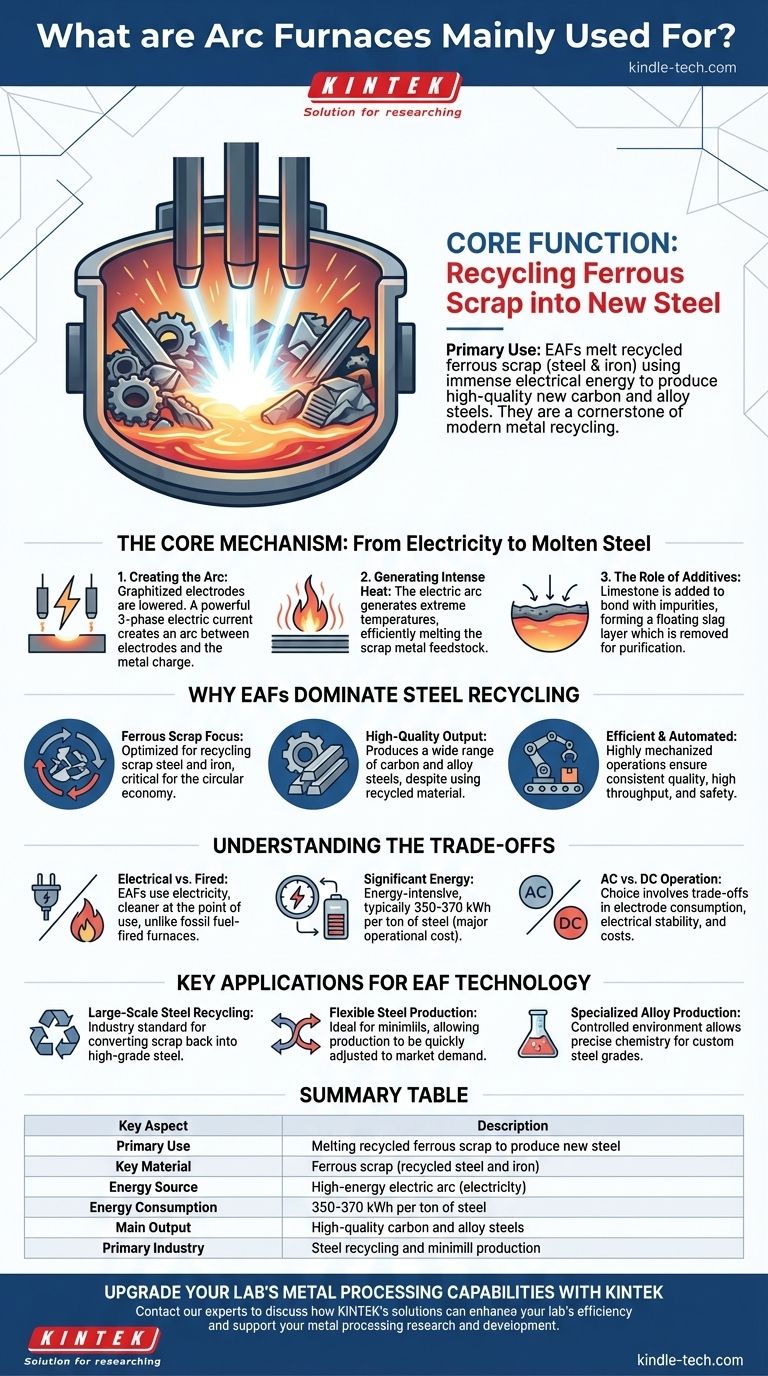

The Core Mechanism: From Electricity to Molten Steel

An electric arc furnace does not burn fuel in the traditional sense. Instead, it leverages the raw power of electricity to generate the extreme temperatures needed to melt metal.

Creating the Arc

The process begins with lowering massive graphitized electrodes into a furnace filled with scrap metal. A powerful three-phase electric current is applied to these electrodes.

An electric arc then forms between the electrodes and the metal charge itself, creating a circuit.

Generating Intense Heat

This arc is a concentrated discharge of electrical energy, which generates immense heat. It is this intense, direct heat that melts the scrap metal efficiently and quickly.

The Role of Additives

During the melting process, materials like limestone are added to the furnace. These additives bond with impurities in the molten metal, forming a layer of slag that floats on top.

This slag is then removed, which is a critical step in purifying the steel before it is tapped from the furnace.

Why Arc Furnaces Dominate Steel Recycling

While other furnace types exist, the EAF is uniquely suited for the specific task of recycling scrap. Its design and operation are optimized for this feedstock.

The Focus on Ferrous Scrap

The primary material, or "charge," for an EAF is ferrous scrap—recycled steel and iron. This makes the EAF a critical component of the circular economy for steel.

High-Quality Steel Production

Despite using recycled material, EAFs are capable of producing a wide range of high-quality steels. They can produce both common carbon steel and more specialized alloy steels by adding specific elements to the molten bath.

An Efficient, Automated Process

Modern arc furnace operations are highly mechanized and automated. This ensures consistent quality, high throughput, and safety in an inherently dangerous industrial environment.

Understanding the Trade-offs

The choice of an EAF is based on specific industrial needs and comes with distinct operational considerations compared to other furnace technologies.

Electrical vs. Fired Furnaces

The industrial furnace landscape includes two general types: electrical and fired. Fired furnaces rely on the combustion of fuel (like gas or oil), while EAFs rely solely on electricity. This makes EAFs cleaner at the point of use, with emissions tied to the source of electricity generation.

Significant Energy Requirements

The process is energy-intensive. A typical EAF requires between 350 and 370 kWh of energy to produce a single ton of steel, a major operational cost and consideration. The exact amount depends on the quality and composition of the scrap being used.

AC vs. DC Operation

Two main types of EAFs exist: those that run on alternating current (AC) and those that use direct current (DC). While both achieve the same goal, the choice between them involves trade-offs in electrode consumption, electrical stability, and operational costs.

Key Applications for EAF Technology

The application of an electric arc furnace is directly tied to the desired outcome and available raw materials.

- If your primary focus is large-scale steel recycling: The EAF is the industry-standard technology for efficiently converting scrap metal back into high-grade steel.

- If your primary focus is flexible steel production: EAFs can be started and stopped more readily than traditional blast furnaces, making them ideal for "minimills" that adjust production to market demand.

- If your primary focus is producing specialized alloy steels from scrap: The controlled EAF environment allows for precise chemistry adjustments, making it perfect for creating custom steel grades.

Ultimately, the electric arc furnace stands as a powerful and indispensable tool for sustainable and versatile steel manufacturing worldwide.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Use | Melting recycled ferrous scrap to produce new steel |

| Key Material | Ferrous scrap (recycled steel and iron) |

| Energy Source | High-energy electric arc (electricity) |

| Energy Consumption | 350-370 kWh per ton of steel |

| Main Output | High-quality carbon and alloy steels |

| Primary Industry | Steel recycling and minimill production |

Upgrade Your Lab's Metal Processing Capabilities with KINTEK

Whether you're involved in materials research, metallurgical testing, or small-scale alloy development, KINTEK provides the laboratory equipment you need to support your steel and metal analysis workflows. Our specialized furnaces and consumables help researchers and quality control labs achieve precise temperature control and reliable results.

Contact our experts today to discuss how KINTEK's solutions can enhance your lab's efficiency and support your metal processing research and development.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What are the advantages of using a vacuum drying oven for rice husk? Preserve Biomass Quality and Purity

- How does a vacuum coater work? Achieve Ultra-Pure, Durable Coatings for Your Products

- What are the disadvantages of quenching? Managing the Risks of Distortion and Cracking

- How is sintering temperature determined? Master the balance between density and distortion.

- What are the advantages of using a vacuum drying oven for Ga0.25Zn4.67S5.08? Protect Your Material’s Integrity.

- What are the 3 phases of quenching process? Master the Cooling Stages for Perfect Hardness

- How does vacuum arc melting work? Unlock High-Purity Metals for Critical Applications

- What is pressureless sintering? Achieve Complex Shapes and High Purity Without External Pressure