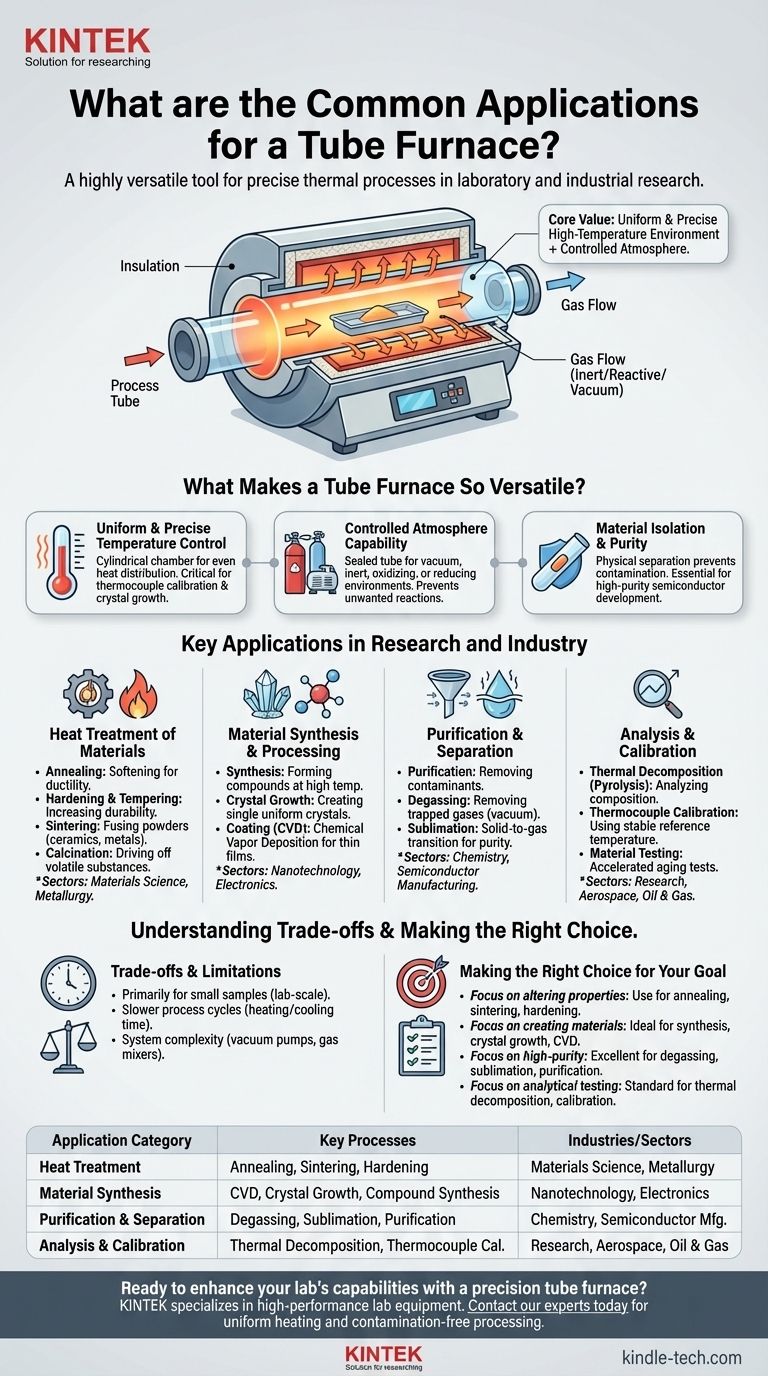

In short, a tube furnace is a highly versatile piece of laboratory and industrial equipment used for a wide range of thermal processes. Its primary applications revolve around heat treatment, material synthesis, purification, and analytical testing, making it essential for fields ranging from materials science and chemistry to nanotechnology and electronics manufacturing.

The core value of a tube furnace is its ability to create an extremely uniform and precisely controlled high-temperature environment. This, combined with its capacity to manage the atmosphere around a sample—from a vacuum to specific reactive or inert gases—makes it indispensable for sensitive and advanced material processing.

What Makes a Tube Furnace So Versatile?

The specific applications of a tube furnace are all rooted in its fundamental design. Understanding these three core features explains why it is the preferred tool for so many critical processes.

Uniform and Precise Temperature Control

A tube furnace's cylindrical heating chamber naturally promotes an even distribution of heat. This thermal uniformity along the length of the tube is critical for processes where every part of the sample must experience the exact same temperature.

This precision is why tube furnaces are trusted for sensitive tasks like thermocouple calibration and crystal growth, where slight temperature variations could ruin the outcome.

Controlled Atmosphere Capability

The most significant advantage is the ability to completely control the gaseous environment. A process tube (typically quartz or alumina) can be sealed at both ends.

This allows operators to either pull a vacuum to remove reactive gases or introduce a specific gas. This enables processes in inert (nitrogen, argon), oxidizing (oxygen), or reducing (hydrogen) atmospheres, which is essential for preventing unwanted chemical reactions or facilitating desired ones.

Material Isolation and Purity

The sample is placed inside the process tube, which isolates it from the furnace's heating elements and insulation. This physical separation prevents contamination, a crucial factor in high-purity applications like semiconductor development and the purification of chemical compounds.

Key Applications in Research and Industry

The design principles above unlock a vast range of applications across scientific and commercial sectors. These can be grouped into several key categories.

Heat Treatment of Materials

This involves altering the physical and chemical properties of a material.

- Annealing: Softening metals or glass to improve ductility.

- Hardening & Tempering: Increasing the hardness and durability of metals.

- Sintering: Fusing powdered materials together with heat, used to create ceramics and metal components.

- Calcination: Heating materials to drive off volatile substances, like converting limestone to lime.

Material Synthesis and Processing

Tube furnaces are used to create or modify advanced materials.

- Synthesis: Forming inorganic and organic compounds at high temperatures.

- Crystal Growth: Creating single, uniform crystals for electronics or research.

- Coating: Processes like Chemical Vapor Deposition (CVD), where gases react to form a thin film on a substrate, are used to produce items like semiconductors and graphene.

Purification and Separation

High temperatures can be used to separate materials or remove impurities.

- Purification: Removing contaminants from organic or inorganic samples.

- Degassing: Removing dissolved or trapped gases from a material, often under vacuum.

- Sublimation: Purifying a substance by transitioning it directly from a solid to a gas, leaving impurities behind.

Analysis and Calibration

The furnace's stability makes it a reliable analytical tool.

- Thermal Decomposition (Pyrolysis): Breaking down compounds with heat in an inert atmosphere to analyze their composition.

- Thermocouple Calibration: Using the known, stable temperature of the furnace as a reference standard.

- Material Testing: Performing accelerated aging or other thermal tests on samples for aerospace, oil and gas, or other industries.

Understanding the Trade-offs and Limitations

While incredibly useful, a tube furnace is not the right tool for every job. Understanding its limitations is key to using it effectively.

Primarily for Small Samples

Most tube furnaces are designed for laboratory-scale work, processing relatively small samples. Their size and batch-style operation make them inefficient for high-volume industrial production compared to continuous-belt or large box furnaces.

Slower Process Cycles

Due to their thermal mass and insulation, tube furnaces can take a significant amount of time to heat up and cool down. This makes them less suitable for applications requiring rapid thermal cycling.

System Complexity

Implementing advanced applications often requires more than just the furnace. Vacuum pumps, gas mixing systems, and multi-zone temperature controllers can add significant cost and complexity to the overall setup.

Making the Right Choice for Your Goal

To select the right process, match your goal to the furnace's core strengths.

- If your primary focus is altering material properties: Use the furnace for annealing, sintering, or hardening, where its precise temperature and atmosphere control are essential for repeatable results.

- If your primary focus is creating new materials: It is ideal for synthesis, crystal growth, or CVD, as the isolated and controlled environment prevents contamination and enables specific chemical reactions.

- If your primary focus is high-purity processing: The furnace excels at degassing, sublimation, or purification, where the ability to use a vacuum or inert gas is critical to removing unwanted substances.

- If your primary focus is analytical testing: Its thermal stability makes it the standard for accurate thermal decomposition studies or the calibration of temperature sensors.

By understanding its core capabilities, you can leverage the tube furnace as a powerful and precise tool for advancing material innovation.

Summary Table:

| Application Category | Key Processes | Industries/Sectors |

|---|---|---|

| Heat Treatment | Annealing, Sintering, Hardening | Materials Science, Metallurgy |

| Material Synthesis | CVD, Crystal Growth, Compound Synthesis | Nanotechnology, Electronics |

| Purification & Separation | Degassing, Sublimation, Purification | Chemistry, Semiconductor Manufacturing |

| Analysis & Calibration | Thermal Decomposition, Thermocouple Calibration | Research, Aerospace, Oil & Gas |

Ready to enhance your lab's capabilities with a precision tube furnace? KINTEK specializes in high-performance lab equipment and consumables, providing tube furnaces that deliver uniform heating, controlled atmospheres, and contamination-free processing—perfect for materials science, chemistry, and electronics R&D. Let us help you achieve precise thermal processing for your most critical applications. Contact our experts today to find the ideal solution for your laboratory needs!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the use of graphite tube? Essential for Extreme Heat & Corrosive Environments

- What is the function of a tube furnace? Achieve Precise High-Temperature Processing in a Controlled Atmosphere

- What are the advantages of using a Hastelloy (HC-276) tubular reactor for studying FeS deposition mechanisms?

- What are the primary functions of a vacuum tube furnace during creep testing? Ensure Data Integrity at 600-800ºC

- What is a quartz heating tube? A Guide to Fast, Precise Infrared Heating

- What is the high temperature of a tube furnace? Unlock the Right Model for Your Application

- What are the advantages of using a Multi-zone Tube Furnace? Enhanced Thermal Uniformity for Diffusion Research

- What is a three zone furnace? Achieve Superior Thermal Control and Uniformity