In essence, a batch type furnace is an industrial heating system that processes a single, discrete load of material at a time. The material is loaded into a chamber, the door is sealed to create a closed environment, the heating cycle is completed, and then the entire load is removed before the next one can begin.

The core value of a batch furnace lies in its flexibility and environmental control. It is designed to handle varied production needs and sensitive processes where each load requires a specific, controlled heating cycle, rather from a continuous, high-volume flow.

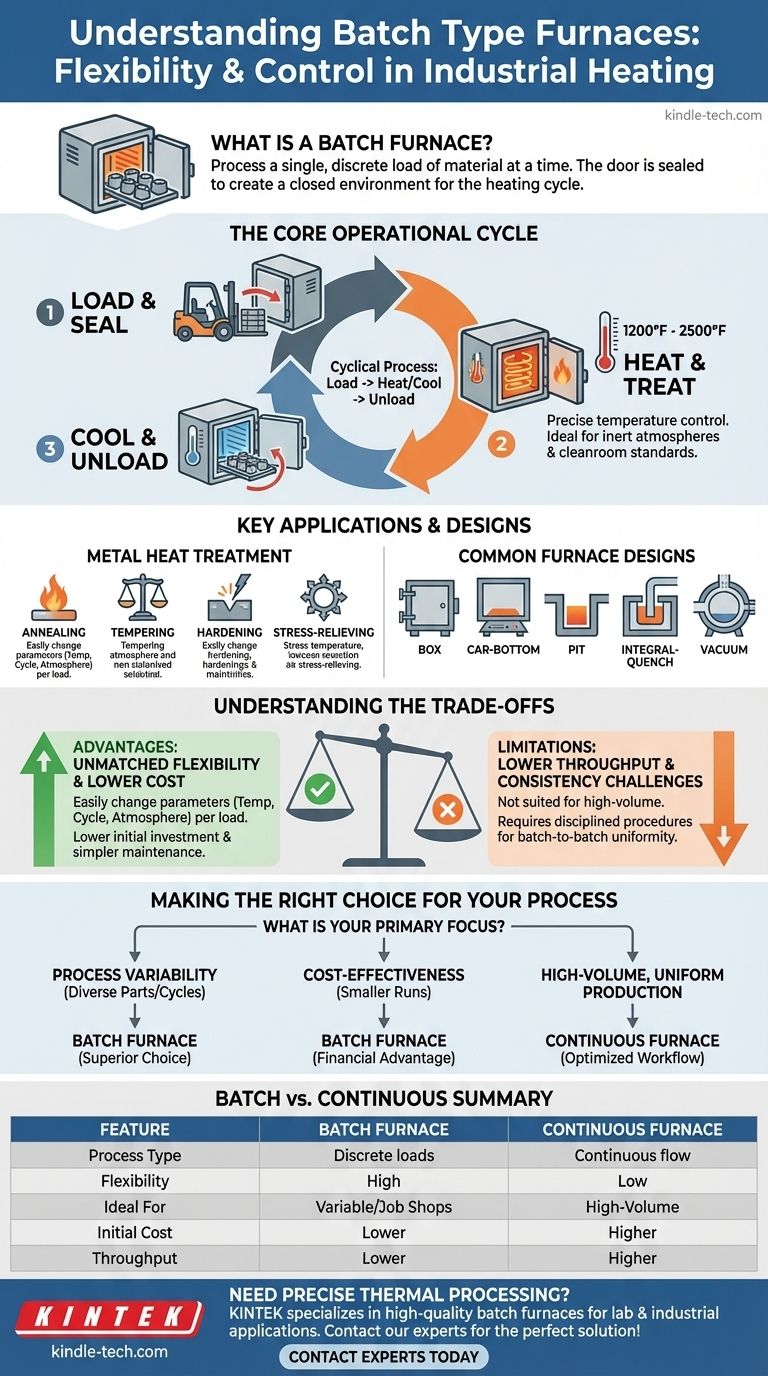

How a Batch Furnace Operates

A batch furnace functions on a simple, cyclical principle. Its design prioritizes control over a single lot of material rather than continuous throughput.

The Core Principle: Processing in Lots

The entire process is centered around the "batch." Materials are loaded together, treated as a single unit throughout the heating and cooling cycle, and then unloaded together.

This method is fundamentally different from a continuous furnace, where materials are constantly fed through heating and cooling zones on a conveyor.

Creating a Controlled Environment

Once the door is closed, the heating chamber is completely sealed from the outside environment. This is a critical feature.

This sealed design makes batch furnaces perfectly suited for processes requiring an inert atmosphere (to prevent oxidation) or adherence to strict cleanroom standards.

The Heating and Cooling Cycle

The temperature profile of a batch furnace can be precisely controlled and adjusted for each new load. The furnace heats up to temperatures between 1200°F and 2500°F, holds the temperature for a specified duration, and then cools down before the batch is removed.

Key Applications and Furnace Types

Batch furnaces are a cornerstone of many thermal processing industries, particularly where precision and adaptability are required.

Metal Heat Treatment

The most common application is for heat-treating metals. This includes processes like annealing, tempering, hardening, and stress-relieving, where precise temperature control is paramount.

Common Furnace Designs

Several designs exist to accommodate different part sizes and loading requirements. Common types include box, car-bottom, pit, integral-quench, and vacuum furnaces.

Understanding the Trade-offs

Choosing a batch furnace involves weighing its significant advantages in flexibility and cost against its inherent limitations in production volume.

Advantage: Unmatched Flexibility

The greatest strength of a batch furnace is its adaptability. You can easily change the temperature, cycle time, and atmosphere between each load, making it ideal for job shops or products with diverse specifications.

Advantage: Lower Cost and Maintenance

Generally, batch furnaces are less mechanically complex than their continuous counterparts. This results in a lower initial investment and simpler, less expensive ongoing maintenance.

Limitation: Lower Throughput

The cyclical nature of loading, heating, and unloading means batch furnaces are not suited for high-volume, standardized production. The process is inherently stop-and-start.

Limitation: Batch-to-Batch Consistency

While the environment within a single batch is highly controlled, ensuring perfect consistency from one batch to the next requires disciplined operational procedures.

Making the Right Choice for Your Process

Selecting the correct furnace technology depends entirely on your specific production goals and the nature of the parts you are treating.

- If your primary focus is process variability: A batch furnace is the superior choice for handling diverse parts with different heating requirements in each load.

- If your primary focus is cost-effectiveness for smaller runs: The lower initial investment and simpler maintenance of a batch furnace provide a significant financial advantage.

- If your primary focus is high-volume, uniform production: You should investigate continuous furnaces, as their design is optimized for a steady, high-throughput workflow.

Ultimately, a batch furnace provides exceptional control and adaptability for individualized thermal processing tasks.

Summary Table:

| Feature | Batch Furnace | Continuous Furnace |

|---|---|---|

| Process Type | Discrete loads (batch) | Continuous flow |

| Flexibility | High (cycle changes per load) | Low (fixed cycle) |

| Ideal For | Variable production, job shops | High-volume, uniform production |

| Initial Cost | Lower | Higher |

| Throughput | Lower | Higher |

Need precise thermal processing for your lab or production line?

KINTEK specializes in high-quality batch furnaces designed for laboratory and industrial heat treatment applications. Whether you require annealing, tempering, or hardening under a controlled atmosphere, our equipment delivers the flexibility and precision you need.

Contact our experts today to find the perfect batch furnace solution for your specific materials and processes!

Visual Guide

Related Products

- Mesh belt controlled atmosphere furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are the main components of an industrial furnace? Explore Essential Elements for Precision Heating

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- How does an atmosphere furnace ensure quality in BN nanotube synthesis? Precision Control for Cup-Stacked Structures

- Why is a horizontal tube furnace with a H2-N2 atmosphere used for NiO pre-treatment? Key to Catalyst Activation

- What is the function of a tube atmosphere furnace in Li2MnSiO4 synthesis? Achieve High-Purity Battery Materials