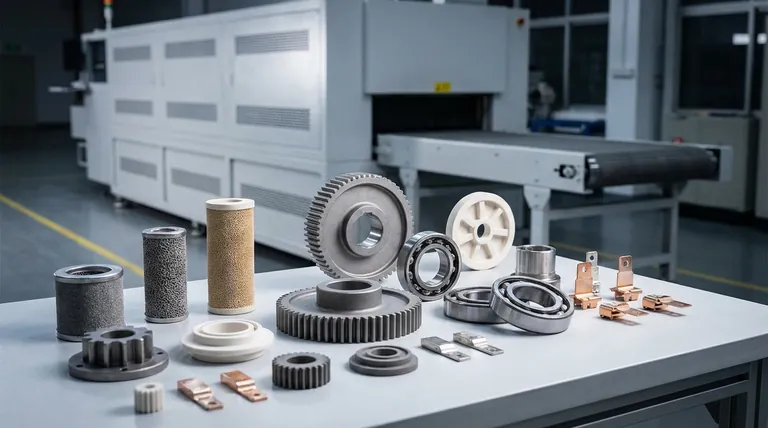

In short, sintered products are used everywhere. They are found in applications ranging from common mechanical parts like gears and bearings to specialized components like medical implants, electrical contacts, and high-performance cutting tools.

The core reason sintering is so widely used is its unique ability to create strong, complex, and precise parts from powdered materials without melting them. This makes it the ideal manufacturing process for materials with extremely high melting points or for applications requiring carefully controlled properties, like porosity.

Why Sintering is the Chosen Process

Sintering is more than just an alternative manufacturing method; it solves fundamental challenges that casting or machining cannot easily address. The decision to use sintering is typically driven by material properties, part complexity, or the need for unique structural characteristics.

Handling High Melting-Point Materials

Many advanced materials, such as tungsten, carbon, and certain ceramics, have melting points so high that melting and casting them is impractical or prohibitively expensive.

Sintering operates below the material's melting point. It uses heat and pressure to bond particles together, making it one of the few viable methods for fabricating parts from these high-performance materials.

Creating Complex and Precise Shapes

Sintering is a cornerstone of powder metallurgy, a process that excels at producing intricate shapes with high precision, often requiring little to no finishing work.

This is why it's used for components like gears, cams, and couplings. The process, including its use in metal 3D printing, allows for consistent production of complex geometries that would be difficult or wasteful to create by machining from a solid block.

Engineering Specific Material Properties

Unlike processes that create a solid, uniform material, sintering allows for precise control over the final part's internal structure.

A key example is controlling porosity. Sintering can be used to create highly porous metal or plastic parts perfect for filters. Conversely, it can be used to create self-lubricating bearings by impregnating the porous structure with oil.

A Survey of Sintered Product Applications

The unique advantages of sintering lead to its adoption across a vast range of industries and products.

Mechanical and Structural Components

This is the largest category for sintered metal parts. They are valued for their strength, wear resistance, and cost-effectiveness in mass production.

Common examples include gears, engine brackets, armatures, and structural parts for machinery and automobiles.

Porous and Filtration Products

The ability to create a network of interconnected pores is a unique feature of the sintering process.

This is leveraged to produce self-lubricating bearings, which hold oil in their porous structure, and a wide variety of metal and plastic filters used in industrial and chemical processing.

Electrical and Magnetic Components

Sintering is critical for producing components where specific electrical or magnetic properties are required.

Applications include electrical contacts, which often combine materials like tungsten and copper, as well as semiconductors and magnetic materials used in electronic devices.

High-Performance and Specialized Materials

For the most demanding applications, sintering is often the only way to manufacture the necessary parts.

This includes cutting tools made from tungsten carbide, wear-resistant medical and dental products, and high-temperature components like tungsten wire filaments.

Understanding the Trade-offs

While powerful, sintering is not the universal solution for all manufacturing needs. It's essential to understand its practical limitations.

Inherent Porosity and Strength

Unless secondary operations are performed, sintered parts typically have some residual porosity.

This can result in lower tensile strength and ductility compared to parts made from fully dense wrought or forged metals. The application must be able to accommodate these properties.

Tooling and Production Volume

Creating the molds and dies for pressing powdered material can represent a significant upfront investment.

Because of this initial cost, sintering is often most cost-effective for medium to high-volume production runs, where the tooling cost can be amortized over many thousands of parts.

Making the Right Choice for Your Goal

Selecting a manufacturing process depends entirely on your specific goals for the component.

- If your primary focus is cost-effective mass production of complex parts: Sintering is an excellent choice for components like gears and cams that require minimal finishing.

- If your primary focus is working with high-temperature materials: Sintering is often the only practical method for processing materials like tungsten, tantalum, or advanced ceramics.

- If your primary focus is creating materials with controlled porosity: Sintering provides unparalleled control for manufacturing products like filters and self-lubricating bearings.

Ultimately, sintering empowers engineers to build components that would otherwise be impossible or impractical to create.

Summary Table:

| Application Category | Key Examples | Primary Benefit of Sintering |

|---|---|---|

| Mechanical/Structural | Gears, bearings, engine brackets | Cost-effective mass production of complex shapes |

| Porous/Filtration | Self-lubricating bearings, metal filters | Controlled porosity for specific functions |

| Electrical/Magnetic | Electrical contacts, semiconductors | Processing high-performance materials |

| High-Performance | Cutting tools, medical/dental implants, filaments | Ability to handle extreme temperatures and wear |

Need to source high-quality sintered components or explore sintering for your lab's material needs? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our expertise can help you select the right materials and processes for creating durable, precise parts. Contact our experts today to discuss how we can support your project with reliable sintering solutions!

Visual Guide

Related Products

- Mesh belt controlled atmosphere furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- Why is a high-precision atmosphere furnace essential for high-nickel cathode sintering? Unlock Battery Performance

- How does an atmosphere furnace ensure quality in BN nanotube synthesis? Precision Control for Cup-Stacked Structures

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- What is the core function of a high-temperature atmosphere sintering furnace in the fabrication of Ni-Al2O3-TiO2 composites?

- Why Use Ultra-High Vacuum Furnaces for LLZO? Ensure Chemical Stability & Interface Integrity in Solid Electrolytes