In short, oil-free diaphragm vacuum pumps are used in any application where creating a clean, dry vacuum is more important than achieving an extremely deep vacuum. They are staples in laboratory, medical, and light industrial settings for tasks like vacuum filtration, rotary evaporation, sterile fluid handling, and gas sampling, where preventing oil contamination is critical.

The decision to use an oil-free diaphragm pump is driven by a need for process purity. Unlike oil-sealed pumps, their core benefit is eliminating the risk of oil vapor contaminating sensitive samples, sterile environments, or analytical results.

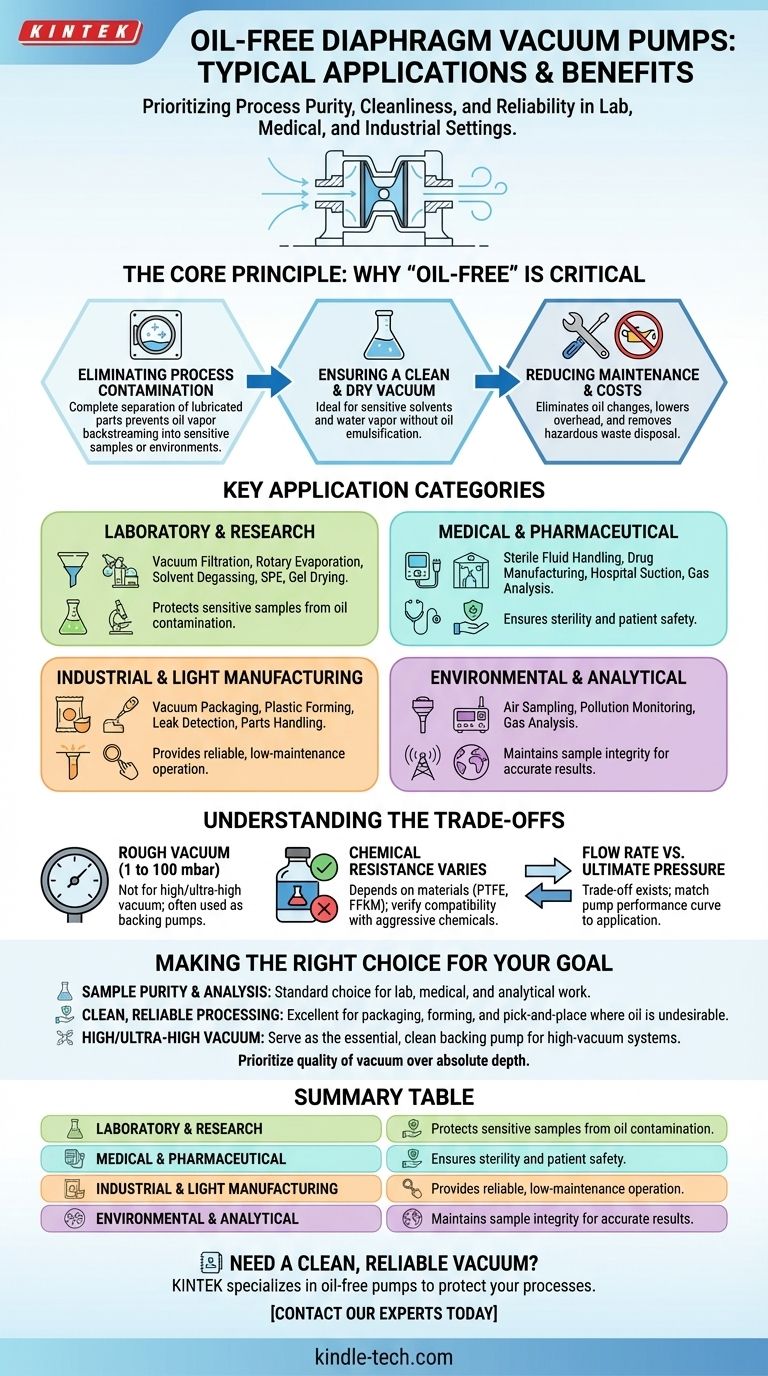

The Core Principle: Why "Oil-Free" Is Critical

The defining feature of a diaphragm pump is its mechanical design, which uses a flexible membrane (diaphragm) to move gas. This simple fact is the source of its primary advantages.

Eliminating Process Contamination

The most significant benefit is the complete separation of lubricated parts from the gas path. This oil-free operation means no oil vapor can backstream into your vacuum chamber or process.

This is non-negotiable in applications where even trace amounts of hydrocarbon contamination could ruin an experiment, invalidate a medical sample, or compromise a sterile product.

Ensuring a Clean and Dry Vacuum

Because no oil is used for sealing or lubrication, the vacuum created is "clean and dry." This makes them ideal for processes involving sensitive solvents or water vapor, which can be easily handled without emulsifying with pump oil.

Reducing Maintenance and Operational Costs

Oil-free pumps eliminate the entire routine of monitoring, changing, and disposing of contaminated pump oil. This lowers maintenance overhead, reduces downtime, and removes a source of hazardous waste.

Key Application Categories

The principle of clean vacuum translates into widespread use across several key sectors. Each application leverages the pump's oil-free nature to protect the integrity of the process.

Laboratory & Research

This is the most common environment for diaphragm pumps. They provide the rough vacuum needed for many benchtop procedures.

Key uses include vacuum filtration, rotary evaporation (roto-vaps), solvent degassing, solid phase extraction (SPE), and gel drying. In each case, the goal is to separate components without introducing a foreign contaminant.

Medical & Pharmaceutical

In medical and pharmaceutical settings, sterility and patient safety are paramount. Oil-free operation is a mandatory requirement.

Applications range from sterile fluid handling and gas analysis for medical instruments to process vacuum for drug manufacturing and aseptic packaging. They are also used for hospital suction systems.

Industrial & Light Manufacturing

Diaphragm pumps are used for clean industrial processes where reliability and low maintenance are valued.

This includes vacuum packaging for food, plastic forming, non-magnetic parts handling with vacuum cups, and airtightness or leak detection testing on production lines.

Environmental & Analytical

When sampling and analyzing air or gasses, the sample must remain unaltered.

Oil-free diaphragm pumps are used for air sampling stations, pollution monitoring equipment, and as a vacuum source for various gas analyzers. The pump's clean operation ensures that the only gasses being measured are from the sample itself.

Understanding the Trade-offs

While highly versatile, oil-free diaphragm pumps are not the solution for every vacuum need. Understanding their limitations is crucial for proper application.

They Provide a "Rough" Vacuum

Diaphragm pumps are designed for low to medium vacuum, typically in the range of 1 to 100 mbar (Torr). They cannot achieve the high or ultra-high vacuum levels required for processes like mass spectrometry or electron microscopy.

In these systems, they are often used as backing pumps or roughing pumps to create the initial low-pressure environment needed for a high-vacuum pump (like a turbomolecular pump) to take over.

Chemical Resistance Varies

While many models are marketed as "chemically resistant," this depends entirely on the materials used for the diaphragm and valves (e.g., PTFE, FFKM). A standard pump can be quickly destroyed by aggressive solvents or acids.

You must always verify that the pump's wetted materials are compatible with the specific chemicals you plan to use.

Flow Rate vs. Ultimate Pressure

There is an inherent trade-off between how much gas a pump can move (flow rate) and the deepest vacuum it can achieve (ultimate pressure). A pump optimized for a deeper vacuum may have a lower flow rate, and vice versa. Matching the pump's performance curve to your application is essential.

Making the Right Choice for Your Goal

The right pump is the one that meets the specific demands of your process.

- If your primary focus is sample purity and sensitive analysis: An oil-free diaphragm pump is the standard choice for lab work, medical processes, and analytical sampling.

- If your primary focus is clean, reliable industrial processing: A diaphragm pump is excellent for packaging, forming, and pick-and-place operations where oil contamination is undesirable.

- If your primary focus is achieving high or ultra-high vacuum: You will need a high-vacuum pump, and a diaphragm pump may serve as the essential, clean backing pump for that system.

Ultimately, choosing this technology is a decision to prioritize the quality of your vacuum over the absolute depth of it.

Summary Table:

| Application Category | Key Uses | Primary Benefit |

|---|---|---|

| Laboratory & Research | Vacuum Filtration, Rotary Evaporation, Solvent Degassing | Protects sensitive samples from oil contamination |

| Medical & Pharmaceutical | Sterile Fluid Handling, Drug Manufacturing, Hospital Suction | Ensures sterility and patient safety |

| Industrial & Light Manufacturing | Vacuum Packaging, Plastic Forming, Leak Detection | Provides reliable, low-maintenance operation |

| Environmental & Analytical | Air Sampling, Pollution Monitoring, Gas Analysis | Maintains sample integrity for accurate results |

Need a clean, reliable vacuum for your sensitive applications?

KINTEK specializes in oil-free diaphragm vacuum pumps and lab equipment, designed to protect your processes from contamination. Our pumps are ideal for laboratory, medical, and light industrial use, ensuring sample integrity and reducing maintenance.

Contact our experts today to find the perfect oil-free vacuum solution for your needs!

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is pyrolysis oil used for? Unlocking Renewable Energy from Waste

- What is pyrolysis conversion of biomass? Unlock the Potential of Waste-to-Energy Technology

- What are the physical properties of pyrolysis? Unlocking the Complex Nature of Pyrolysis Oil

- What is ethylene cracking furnace? The High-Temperature Heart of Petrochemical Production

- How does cooling rate affect mechanical properties? Master the Strength vs. Ductility Trade-off

- What is the source of bio-oil? Unlock Renewable Energy from Biomass

- How is temperature tracking managed in Ultra Freezers? From Basic Charts to Smart Alerts

- What is the thickness of film? The Critical Design Parameter for Material Performance