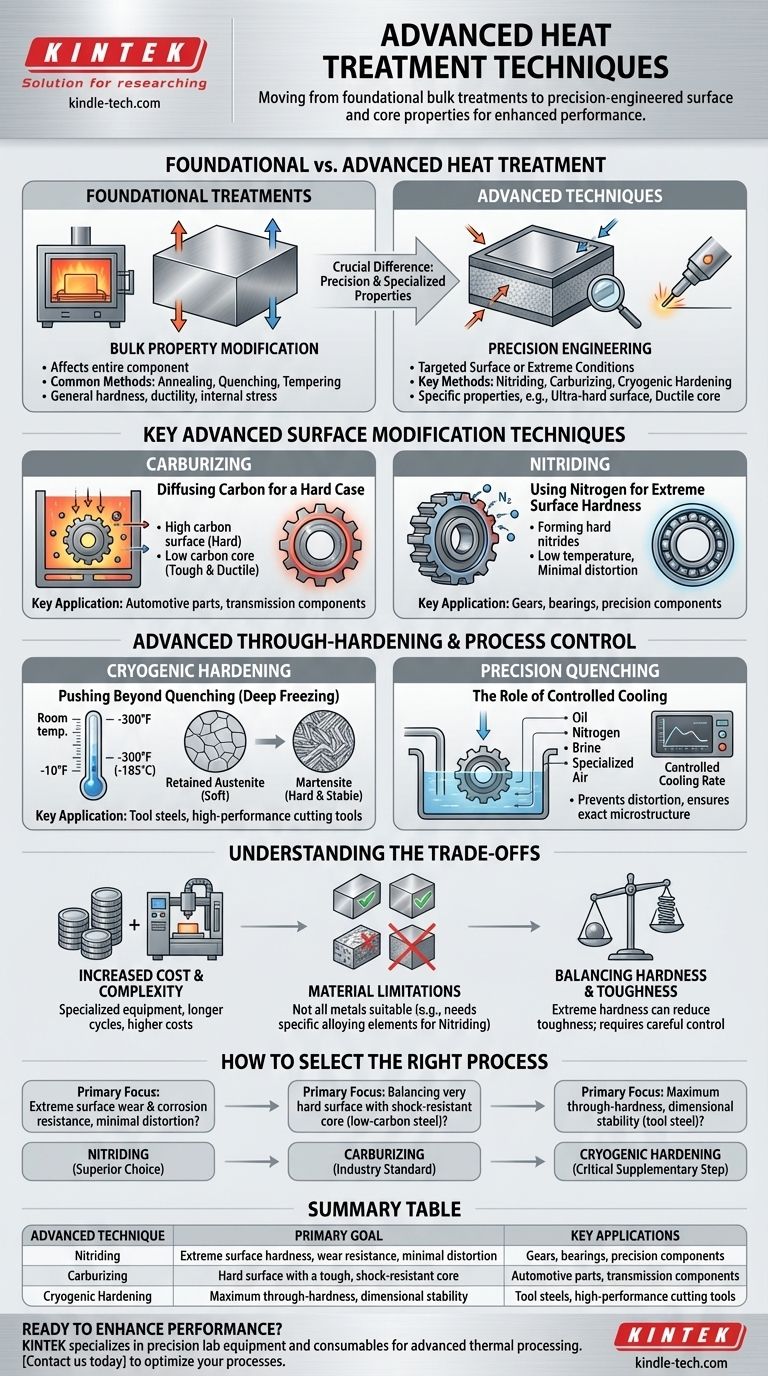

To understand advanced heat treatments, you must first distinguish them from foundational techniques. While common methods like annealing and simple quenching modify the bulk properties of a metal, advanced techniques offer a higher degree of precision, often by altering the surface chemistry or pushing material transformations to their limits. Key advanced processes include nitriding, cryogenic hardening, and specialized carburizing methods.

The crucial difference is moving from simply heating and cooling the entire part to precisely engineering specific properties, such as creating an ultra-hard surface on a component while maintaining a ductile, tough core.

Foundational vs. Advanced Heat Treatment

Before exploring advanced methods, it's essential to understand the baseline. The goal of any heat treatment is to manipulate a metal's microstructure to achieve desired mechanical properties.

The Goal of Foundational Treatments

Most common heat treatments—annealing, normalizing, quenching, and tempering—are designed to affect the entire component.

They modify bulk properties like overall hardness, ductility, and internal stresses. For example, annealing makes a metal softer and easier to machine, while quenching and tempering create a combination of high hardness and toughness.

What Defines an "Advanced" Technique?

Advanced techniques are defined by their precision and the specialized properties they create, which are often impossible to achieve with foundational methods.

These processes typically involve thermochemical diffusion, where elements are introduced into the surface of the part, or extreme temperature ranges, like sub-zero cryogenic treatments. The goal is targeted performance enhancement, not just general property changes.

Key Advanced Surface Modification Techniques

Many advanced techniques focus on creating a "case," or a hardened surface layer, that is fundamentally different from the metal underneath. This creates a composite part with a unique combination of properties.

Carburizing: Diffusing Carbon for a Hard Case

Carburizing is a process that introduces carbon into the surface of low-carbon steel at high temperatures.

This creates a surface with high carbon content that can be quenched to become extremely hard, while the low-carbon core remains soft and tough. This is ideal for parts that need to resist wear while also absorbing shock, such as gears and bearings.

Nitriding: Using Nitrogen for Extreme Surface Hardness

Nitriding diffuses nitrogen into the surface of a steel part, forming hard nitride compounds.

Unlike carburizing, this process is often performed at lower temperatures and typically doesn't require a rapid quench, which significantly reduces the risk of part distortion. Nitrided surfaces offer exceptional wear resistance, anti-galling properties, and improved fatigue life.

Advanced Through-Hardening and Process Control

Beyond surface modification, advanced techniques also enhance properties throughout the entire part or apply an extreme level of control to conventional processes.

Cryogenic Hardening: Pushing Beyond Quenching

Cryogenic hardening, or deep freezing, is a supplementary treatment performed after quenching. Parts are cooled to temperatures as low as -300°F (-185°C).

This process transforms any remaining soft crystal structures (retained austenite) into the very hard martensite structure. The result is a more uniform, stable, and wear-resistant component with significantly improved durability.

Precision Quenching: The Role of Controlled Cooling

While quenching is a foundational technique, the methods used in critical industries like aerospace are highly advanced.

The choice of quenchant—such as oil, nitrogen, brine, or specialized air—and the precise control over the cooling rate are critical variables. This level of control prevents distortion and cracking in complex, high-value components while ensuring the exact desired microstructure is achieved.

Understanding the Trade-offs

Advanced techniques provide superior performance but come with important considerations that may make them unsuitable for every application.

Increased Cost and Complexity

These processes require specialized furnaces, controlled atmospheres, and sophisticated monitoring equipment. The added complexity and longer cycle times result in significantly higher costs compared to simple hardening and tempering.

Material Limitations

Not all metals are suitable for every advanced process. For example, nitriding is most effective on steels containing specific alloying elements like chromium, molybdenum, and aluminum that readily form hard nitrides.

Balancing Hardness and Toughness

While these techniques excel at creating extreme hardness, this can sometimes lead to reduced toughness or increased brittleness if the process is not controlled perfectly. The selection of the right case depth and core properties is a critical engineering decision.

How to Select the Right Process

Your choice should be dictated entirely by the primary performance requirement of the component.

- If your primary focus is extreme surface wear and corrosion resistance with minimal distortion: Nitriding is often the superior choice.

- If your primary focus is balancing a very hard surface with a shock-resistant core in a low-carbon steel: Carburizing is the well-established industry standard.

- If your primary focus is achieving maximum through-hardness, dimensional stability, and service life in a tool steel: Cryogenic hardening is a critical supplementary step after quenching.

Ultimately, adopting an advanced heat treatment is about identifying a specific performance weakness and applying a precise metallurgical solution to overcome it.

Summary Table:

| Advanced Technique | Primary Goal | Key Applications |

|---|---|---|

| Nitriding | Extreme surface hardness, wear resistance, minimal distortion | Gears, bearings, precision components |

| Carburizing | Hard surface with a tough, shock-resistant core | Automotive parts, transmission components |

| Cryogenic Hardening | Maximum through-hardness, dimensional stability | Tool steels, high-performance cutting tools |

Ready to enhance your component performance with advanced heat treatment?

KINTEK specializes in precision lab equipment and consumables for advanced thermal processing. Our solutions are designed to help you achieve superior surface hardness, wear resistance, and material longevity. Whether you're working with tool steels, automotive components, or precision parts, we provide the reliable equipment and expert support you need to push the limits of material performance.

Contact us today to discuss your specific heat treatment challenges and discover how KINTEK can help you optimize your processes for maximum durability and efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the advantages of using a Spark Plasma Sintering (SPS/FAST) system for LLZTO? Rapid Densification & Purity

- What are the advantages of double layer sintering? Unlock Superior Material Performance and Integration

- What is the capacity of a furnace? From Home Heating to Industrial Processes

- How does temperature monitoring affect nickel alloys in SPS? Ensure Precision for High-Performance Sintering

- What role do high-temperature furnaces play in LFR corrosion testing? Achieve Critical Thermal Stability

- What is the study of biomass pyrolysis? Transforming Waste into Valuable Biochar, Bio-oil, and Syngas

- How is vacuum heating equipment used for solid-state battery cathodes? Optimize Drying for Superior Battery Performance

- Is brazing done in a vacuum furnace? Achieve Superior Joint Strength and Purity