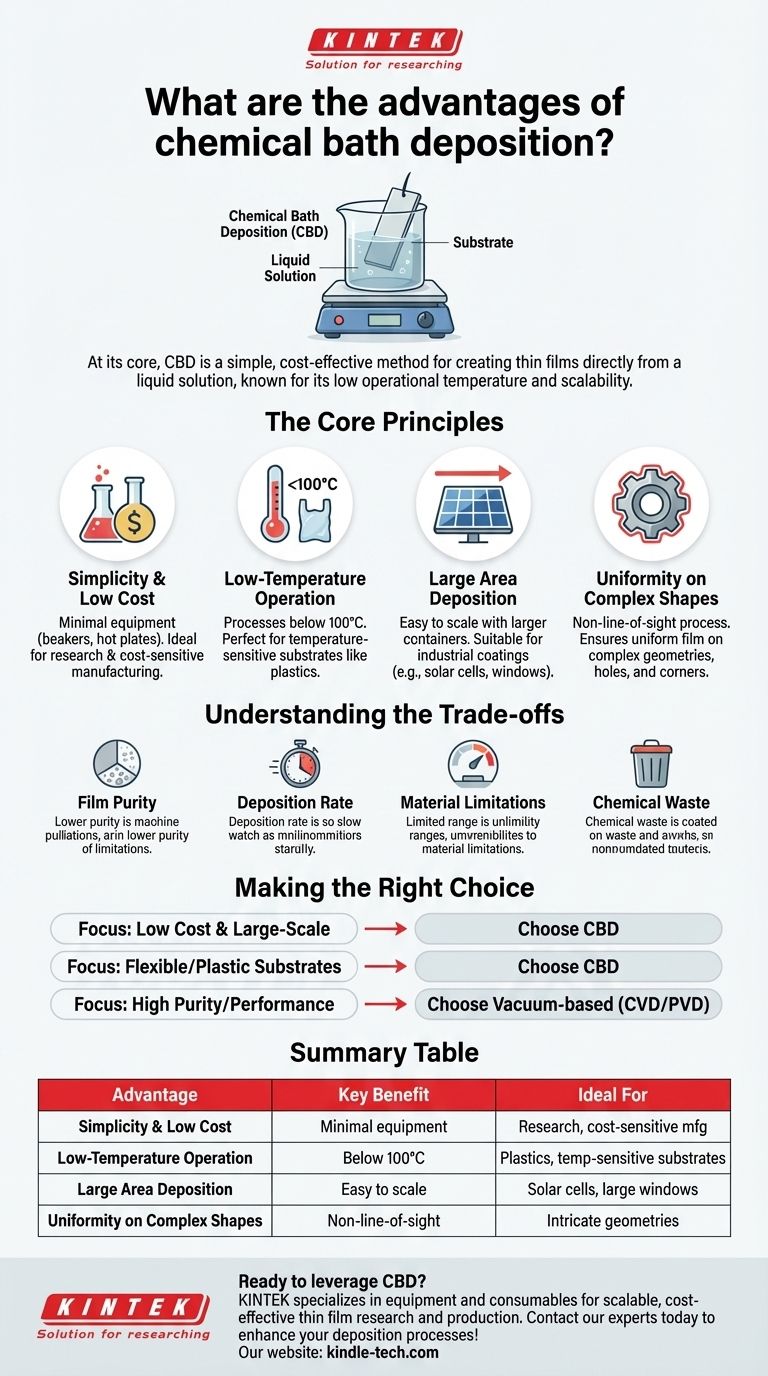

At its core, Chemical Bath Deposition (CBD) is a remarkably simple and cost-effective method for creating thin films directly from a liquid solution. Unlike vapor-based techniques, it involves immersing a substrate into a controlled chemical bath where ions slowly precipitate to form a solid film on the substrate's surface. Its primary advantages lie in its low operational temperature and scalability, making it suitable for applications where other methods are impractical or too expensive.

While often confused with Chemical Vapor Deposition (CVD), Chemical Bath Deposition (CBD) offers a distinct set of advantages rooted in its solution-based, low-temperature nature, making it the ideal choice for cost-sensitive, large-area applications and temperature-sensitive substrates like plastics.

The Core Principles of Chemical Bath Deposition

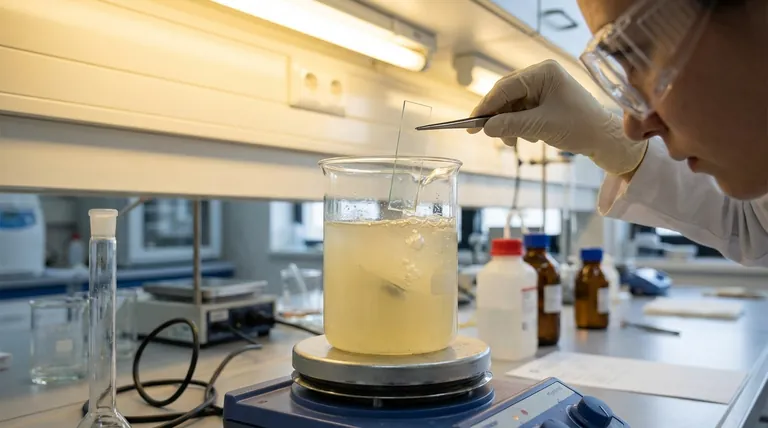

Chemical Bath Deposition operates on the principle of controlled precipitation from an aqueous solution. A substrate is submerged in a bath containing dissolved chemical precursors. By carefully controlling parameters like temperature, pH, and concentration, the solution becomes supersaturated, causing the desired material to slowly precipitate and form a thin, uniform film on the substrate.

Simplicity and Low Cost

The equipment required for CBD is exceptionally simple and inexpensive. It often consists of little more than beakers, stirrers, and a hot plate. This dramatically lowers the barrier to entry for research and manufacturing compared to complex vacuum-based systems.

Low-Temperature Operation

One of the most significant advantages of CBD is its low processing temperature, typically operating well below 100°C (212°F). This allows for the deposition of films onto a wide variety of substrates, including flexible polymers and plastics, which would be damaged or destroyed by the high temperatures of methods like CVD.

Large Area Deposition

Scaling up CBD is straightforward and cost-effective. To coat a larger area, you simply need a larger container for the chemical bath. This makes the technique highly suitable for industrial applications requiring large-scale coatings, such as solar cells or window glazing.

Uniformity on Complex Shapes

Because the substrate is fully immersed in the solution, CBD is a non-line-of-sight process. This ensures that a uniform film is deposited over all surfaces, including those with complex geometries, holes, and sharp corners, without needing to rotate the substrate.

Understanding the Trade-offs

No deposition technique is perfect, and CBD's strengths are balanced by specific limitations. Understanding these trade-offs is critical for selecting the right process for your application. The confusion with Chemical Vapor Deposition (CVD), a high-temperature gas-phase process, often obscures these crucial differences.

Film Purity and Density

CBD films can sometimes incorporate impurities from the solvent (like hydroxides or water molecules), potentially leading to lower purity and density compared to films grown in a vacuum environment like CVD or Physical Vapor Deposition (PVD). Post-deposition annealing is often required to improve film quality.

Deposition Rate and Control

The deposition rate in CBD is generally slow, which can be a limitation for high-throughput manufacturing. While parameters can be controlled, achieving the same level of precise, layer-by-layer thickness control seen in advanced vacuum techniques can be challenging.

Material Limitations

CBD is only suitable for materials that can be precipitated from an aqueous or solvent-based solution under controlled conditions. This limits the range of materials compared to a more versatile process like CVD, which can deposit a vast array of metals, ceramics, and alloys from gaseous precursors.

Chemical Waste

As a solution-based technique, CBD inherently generates chemical waste from the depleted bath. Managing and disposing of this waste is an environmental and cost consideration that is not present in most vapor-phase processes.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on your project's specific constraints and performance requirements.

- If your primary focus is low cost and large-scale production: CBD is an outstanding choice due to its simple equipment and scalability.

- If your primary focus is depositing on flexible or plastic substrates: CBD's low-temperature nature makes it one of the few viable and effective options.

- If your primary focus is the highest possible film purity and density for high-performance electronics: A vacuum-based method like CVD or PVD would likely be a better fit.

Ultimately, choosing Chemical Bath Deposition is a strategic decision that prioritizes accessibility and scalability for specific material systems.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Simplicity & Low Cost | Minimal equipment (beakers, hot plates) | Research labs, cost-sensitive manufacturing |

| Low-Temperature Operation | Processes below 100°C (212°F) | Temperature-sensitive substrates like plastics |

| Large Area Deposition | Easy to scale with larger containers | Solar cells, large window coatings |

| Uniformity on Complex Shapes | Non-line-of-sight deposition | Components with holes, sharp corners, or intricate geometries |

Ready to leverage the advantages of Chemical Bath Deposition in your lab? KINTEK specializes in providing the equipment and consumables that support scalable, cost-effective thin film research and production. Whether you're developing solar cells, coatings for flexible electronics, or large-area applications, our solutions are designed to meet your specific needs. Contact our experts today to discuss how we can enhance your deposition processes!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- What is the process of coating deposition? A Step-by-Step Guide to Thin Film Engineering

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating