In essence, diamond coatings impart the superior properties of diamond—extreme hardness, low friction, and chemical resistance—onto the surface of a less-capable material. This functional upgrade dramatically enhances durability and performance in demanding applications, from high-speed cutting tools to long-lasting medical implants.

Applying a diamond coating is not just about making a surface harder; it's about fundamentally transforming its performance characteristics. The true value lies in combining the strength and cost-effectiveness of a bulk substrate material with the unparalleled surface properties of diamond.

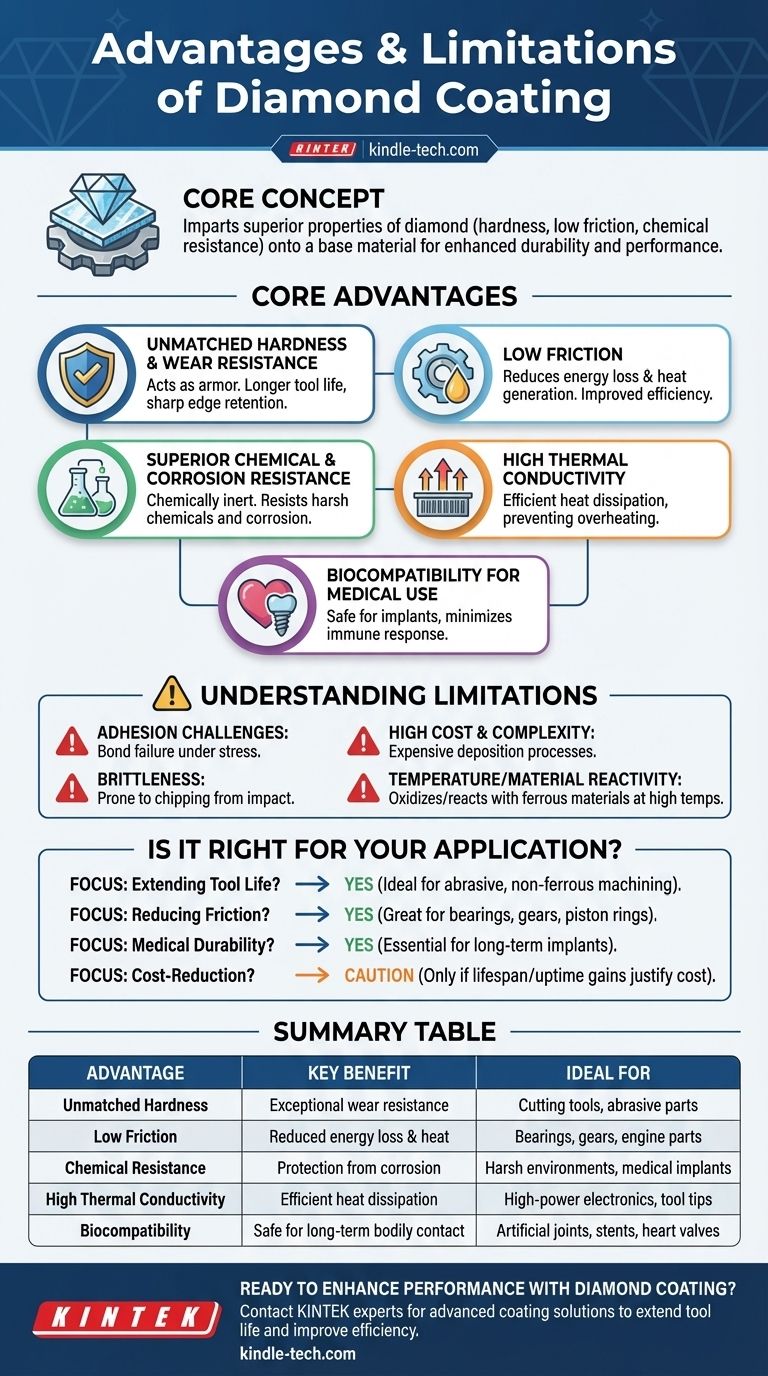

The Core Advantages of Diamond Coating Explained

Understanding why diamond coatings are chosen requires looking beyond a single attribute. It is the unique combination of several elite properties that makes them a powerful solution for complex engineering challenges.

Unmatched Hardness and Wear Resistance

Diamond is the hardest material known. When applied as a thin film, it acts as a suit of armor for the underlying component.

This extreme hardness provides exceptional resistance to abrasive wear and scratching. For a cutting tool, this directly translates to a longer operational life and the ability to maintain a sharp edge for cleaner, more precise cuts.

Exceptionally Low Friction

Diamond and Diamond-Like Carbon (DLC) coatings have a very low coefficient of friction, in some cases comparable to that of Teflon. However, unlike Teflon, they are also incredibly hard.

This high lubricity reduces the energy lost to friction between moving parts. The result is less heat generation, improved efficiency, and a significant reduction in surface wear, which is critical for components like bearings, gears, and engine parts.

Superior Chemical and Corrosion Resistance

Diamond is chemically inert, meaning it does not readily react with other substances. This makes diamond-coated parts highly resistant to corrosion and attack from harsh chemicals.

This property is vital for components used in corrosive environments or for medical implants that must survive for decades within the human body without degrading or leaching harmful materials.

High Thermal Conductivity

Diamond possesses the highest thermal conductivity of any bulk material. A diamond coating can efficiently draw heat away from a critical point, such as the tip of a cutting tool or a high-power electronic component.

By dissipating heat, the coating prevents the underlying material from overheating, which can cause it to soften, deform, or fail prematurely.

Biocompatibility for Medical Use

Specific types of diamond coatings, particularly DLC, are biocompatible. The human body does not recognize them as foreign objects, which prevents an immune response or rejection.

Combined with their wear resistance and chemical inertness, this makes them an ideal surface for medical implants like artificial joints, stents, and heart valves, minimizing wear debris and ensuring long-term stability.

Understanding the Trade-offs and Limitations

While powerful, diamond coatings are not a universal solution. Acknowledging their limitations is crucial for successful implementation.

The Challenge of Adhesion

The single greatest challenge is ensuring the diamond film sticks securely to the substrate. The bond between the coating and the base material can be a point of failure, especially under high stress or thermal cycling.

Differences in thermal expansion between the diamond film and the substrate can cause immense internal stress, leading to delamination or cracking.

Brittleness Under Impact

While extremely hard, diamond is also brittle. A sharp, direct impact can cause the coating to chip or fracture. It resists abrasion excellently but may not handle sudden shocks as well as a tougher, more ductile material.

High Cost and Process Complexity

The deposition processes used to create diamond coatings, such as Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD), are sophisticated and require expensive equipment. This makes diamond-coated components significantly more costly than their uncoated counterparts.

Temperature and Material Reactivity

In the presence of oxygen, diamond begins to oxidize and convert to graphite at temperatures around 700°C, losing its beneficial properties. Furthermore, diamond can react chemically with ferrous materials (iron, steel) at high temperatures, causing rapid tool wear. This makes it better suited for machining non-ferrous materials like aluminum or composites.

Is Diamond Coating Right for Your Application?

Base your decision on your primary performance requirement and whether the benefits justify the cost and complexity.

- If your primary focus is extending tool life and cutting performance: The extreme hardness and thermal conductivity make it an ideal choice, especially when machining abrasive, non-ferrous materials like aluminum alloys, graphite, and composites.

- If your primary focus is reducing friction in moving parts: The low coefficient of friction offers significant advantages for high-performance components like bearings, piston rings, and gears where efficiency and wear reduction are critical.

- If your primary focus is biocompatibility and durability in medical devices: Its chemical inertness and wear resistance are essential for implants that must last for decades inside the body without causing adverse reactions.

- If your primary focus is cost-reduction on a component: Be cautious; the high initial cost of diamond coating is only justified when it leads to significant, measurable improvements in lifespan, machine uptime, or overall system performance.

Ultimately, leveraging a diamond coating is a strategic engineering decision to achieve a level of surface performance that the base material alone cannot provide.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Unmatched Hardness | Exceptional wear resistance | Cutting tools, abrasive parts |

| Low Friction | Reduced energy loss & heat | Bearings, gears, engine parts |

| Chemical Resistance | Protection from corrosion | Harsh environments, medical implants |

| High Thermal Conductivity | Efficient heat dissipation | High-power electronics, tool tips |

| Biocompatibility | Safe for long-term bodily contact | Artificial joints, stents, heart valves |

Ready to enhance your components with the superior performance of a diamond coating?

At KINTEK, we specialize in advanced coating solutions for laboratories and industrial applications. Our expertise can help you determine if a diamond coating is the right strategic choice to extend the life of your cutting tools, improve the efficiency of your moving parts, or ensure the durability of your medical devices.

Contact our experts today to discuss your specific needs and discover how KINTEK's lab equipment and consumables can deliver measurable improvements in performance and cost-effectiveness for your operation.

Visual Guide

Related Products

- Laboratory CVD Boron Doped Diamond Materials

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the carbon footprint of diamond mining? Uncovering the True Environmental and Ethical Cost

- Why are non-active BDD anodes selected for wastewater treatment? Achieve Total Pollutant Mineralization

- What is the purpose of performing anodic polarization on BDD electrodes? Ensure Accurate & Reproducible Research Results

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is the role of an HFCVD reactor in synthesizing boron-doped diamond? Expert Guide to Diamond Gas Activation