The core advantages of Diamond-Like Carbon (DLC) coating are its exceptional hardness, low coefficient of friction, and high corrosion resistance. This unique combination makes it a highly effective surface treatment for extending the life and improving the performance of components in a vast range of applications, from automotive engines to medical implants.

DLC is not a single material but a family of amorphous carbon coatings. The key to leveraging its benefits is understanding that its specific properties—like hardness or friction—can be precisely engineered, allowing you to match the coating's characteristics to the specific demands of your application.

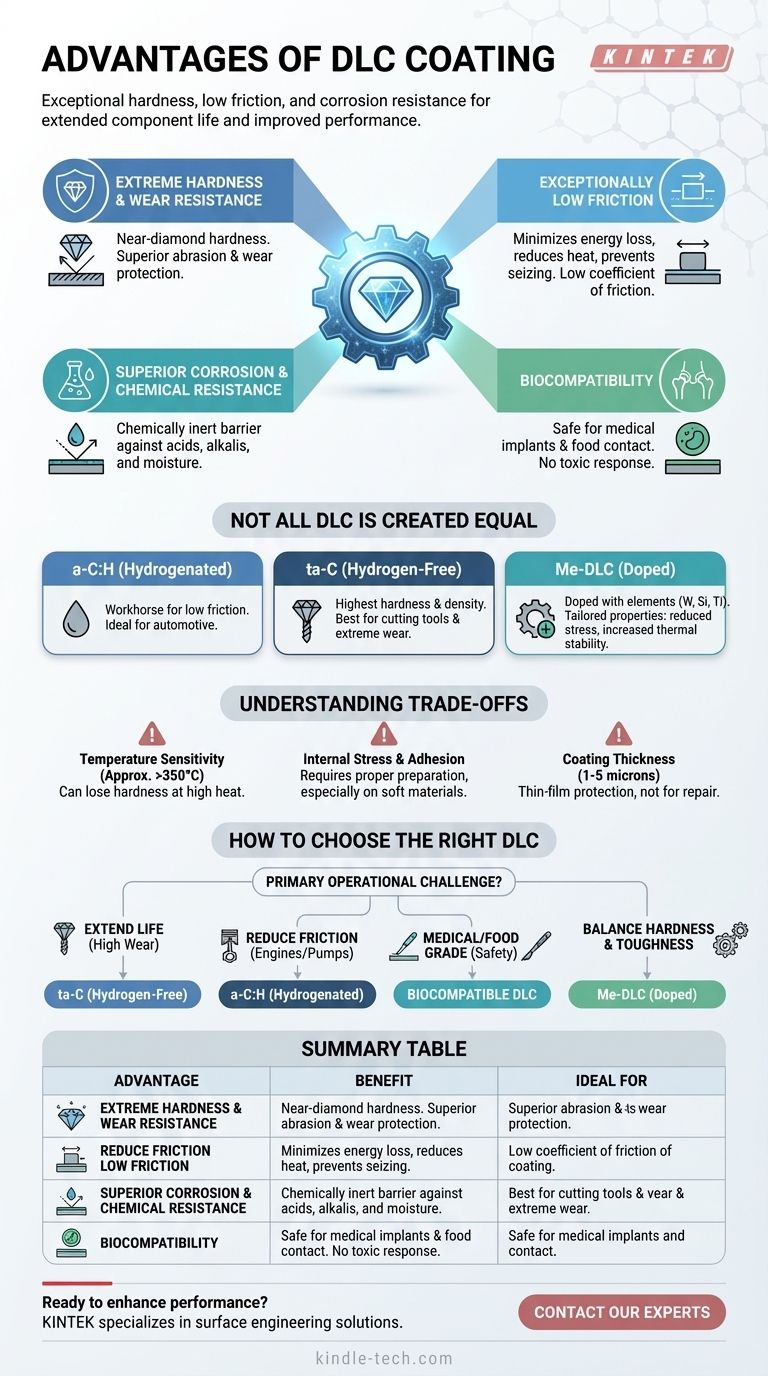

The Core Properties of DLC Coatings

Diamond-Like Carbon coatings are applied as thin films, typically using plasma-assisted chemical vapor deposition (PACVD) or physical vapor deposition (PVD) processes. The resulting film structure gives it a unique blend of the properties of natural diamond and graphite.

Extreme Hardness and Wear Resistance

DLC coatings are exceptionally hard, often falling between natural diamond and sapphire on the Mohs scale. This hardness provides a robust protective layer on the surface of a component.

This directly translates to superior abrasion and wear resistance. The coating acts as a shield, preventing the underlying material from being scratched, scored, or worn down by contact with other surfaces.

Exceptionally Low Friction

One of the most significant advantages of DLC is its extremely low coefficient of friction, in some cases approaching that of Teflon or even wet ice on wet ice.

This property is critical for moving parts. By reducing friction, DLC coatings minimize energy loss, reduce heat generation, and prevent components from seizing under high loads.

Superior Corrosion and Chemical Resistance

DLC coatings are chemically inert. This means they do not react with most acids, alkalis, or solvents.

This inertness creates a highly effective barrier against corrosion and chemical attack. The coating seals the substrate material, protecting it from moisture and aggressive substances that would otherwise cause it to degrade.

Biocompatibility

Certain formulations of DLC are biocompatible, meaning they do not produce a toxic or immunological response when exposed to the human body or bodily fluids.

This makes DLC an ideal coating for medical implants, surgical tools, and food processing equipment. It provides a safe and durable surface that enhances performance without posing a risk to health.

Not All DLC is Created Equal

Understanding the different types of DLC is crucial for selecting the right solution. The properties can vary significantly based on the ratio of diamond-like (sp3) to graphitic (sp2) bonds and the inclusion of other elements.

Hydrogenated Amorphous Carbon (a-C:H)

This is the most common and versatile form of DLC. It is valued for its very low friction and is considered the workhorse for many industrial and automotive applications where reducing drag and wear is the primary goal.

Hydrogen-Free Tetrahedral Amorphous Carbon (ta-C)

Often considered the "purest" form of DLC, ta-C has the highest concentration of diamond-like sp3 bonds. This gives it the greatest hardness and density in the DLC family.

It is the preferred choice for the most demanding applications, such as protecting cutting tools, where extreme wear resistance is paramount.

Doped and Metal-Containing DLC (Me-DLC)

Engineers can introduce other elements, such as Tungsten, Silicon, or Titanium, into the carbon matrix. This process, known as doping, modifies the coating's properties.

Doping can be used to reduce internal stress, increase thermal stability, or alter electrical conductivity, tailoring the coating for specialized applications where standard DLC might fall short.

Understanding the Trade-offs and Limitations

While powerful, DLC is not a universal solution. Being aware of its limitations is key to successful implementation.

Temperature Sensitivity

The primary limitation of most DLC coatings is their thermal stability. When exposed to temperatures typically above 350°C (660°F) in a normal atmosphere, the diamond-like structure can begin to convert to graphite, causing it to lose its hardness and beneficial properties.

Internal Stress and Adhesion

The extreme hardness of DLC can create high internal compressive stress within the thin film. Without proper substrate preparation and deposition processes, this stress can lead to challenges with adhesion, especially on softer materials or complex geometries.

Coating Thickness

DLC is a thin-film coating, typically applied in thicknesses of only 1 to 5 microns. It is designed to protect a surface, not to rebuild it or repair significant geometric defects.

How to Choose the Right DLC for Your Application

Selecting the correct coating requires a clear understanding of your primary operational challenge.

- If your primary focus is extending the life of cutting tools or high-wear components: The superior hardness of a hydrogen-free (ta-C) coating is your best choice.

- If your primary focus is reducing friction in engines, pumps, or bearings: A hydrogenated (a-C:H) coating provides an excellent balance of low friction and cost-effectiveness.

- If your application is for medical implants or food-grade machinery: Ensure you specify a DLC coating that is certified for its biocompatibility.

- If you need to balance hardness with toughness on a softer material: A metal-doped (Me-DLC) coating can reduce internal stress and improve adhesion.

By matching the specific type of DLC to your unique challenge, you can effectively leverage its properties to achieve significant gains in performance and reliability.

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Extreme Hardness | Superior wear & abrasion resistance | Cutting tools, high-wear components |

| Low Friction | Minimizes energy loss & heat generation | Engine parts, bearings, pumps |

| Corrosion Resistance | Barrier against chemicals & moisture | Harsh environments, medical devices |

| Biocompatibility | Safe for medical & food-grade use | Surgical tools, implants, food machinery |

Ready to enhance your component's performance and lifespan with a precision DLC coating?

KINTEK specializes in advanced lab equipment and consumables for surface engineering, helping you select and apply the ideal DLC solution for your specific needs—whether for automotive, medical, or industrial applications.

Contact our experts today to discuss how we can tailor a DLC coating to solve your wear, friction, or corrosion challenges!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How do you apply diamond-like coating? Achieve Superior Surface Performance with DLC

- Why is it necessary to use a vacuum pump to reach low pressures before PECVD for MOF modification? Ensure Deep Diffusion

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- What is the temperature at which the PECVD is carried out? Optimize Your Thin Film Deposition Process

- What are the different types of plasma used in PECVD? Choose Between DC, RF, and Microwave Plasma Sources

- What is the temperature of plasma enhanced CVD? Achieve High-Quality Deposition on Temperature-Sensitive Substrates