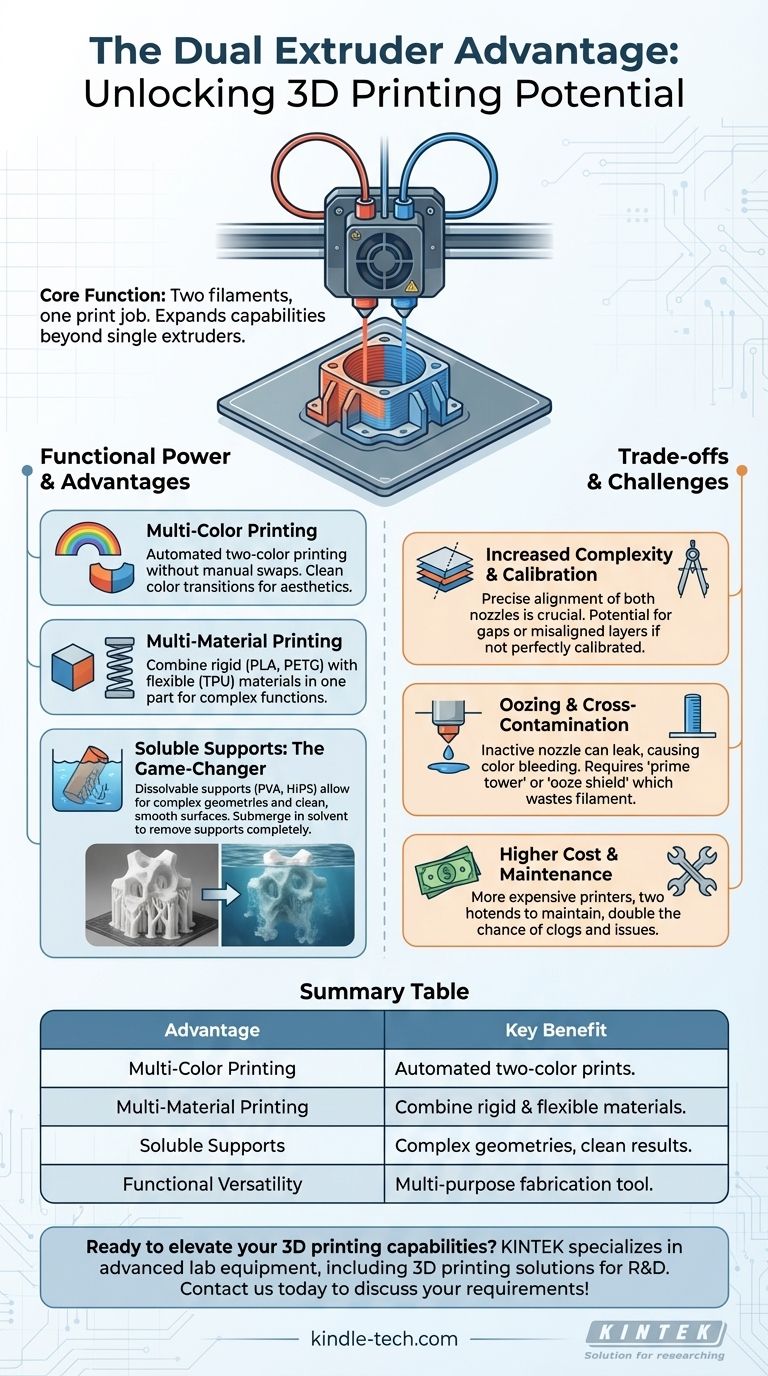

At their core, dual extruders fundamentally expand what a 3D printer can create. They allow a single print job to use two different filaments, which enables printing with multiple colors or, more importantly, multiple material types. While two-color printing can be simulated on a single extruder with manual filament swaps, a dual extruder automates this process and unlocks advanced functional capabilities.

The true advantage of a dual extruder isn't just creating colorful models; it's the ability to print with soluble support materials. This unlocks the freedom to create highly complex geometric shapes that are difficult or impossible to produce with a single extruder.

Beyond Aesthetics: The Functional Power of Dual Extrusion

While multi-color printing is the most visible benefit, the most significant advantages are functional. A second extruder transforms the printer from a single-purpose tool into a more versatile fabrication platform.

Multi-Color Printing

This is the most straightforward advantage. A dual extruder allows you to print an object with two distinct, clean colors without any manual intervention during the printing process.

Your slicer software handles the logic, telling the printer exactly when to switch between the two loaded filaments. This is a major convenience over pausing a print to swap filament by hand.

Multi-Material Printing

This capability allows you to combine filaments with different physical properties into a single part.

For example, you could print a rigid electronics enclosure (using PLA or PETG) with integrated flexible, rubber-like buttons (using TPU). This opens the door to creating more complex and functional end-use parts directly off the print bed.

Soluble Supports: The True Game-Changer

This is arguably the most powerful application of dual extrusion. For complex models with intricate overhangs, internal cavities, or delicate features, support structures are required.

Removing standard supports can be difficult and often leaves marks or breaks fragile parts of the model. A dual extruder solves this by printing the model with a standard material and the supports with a soluble filament (like PVA, which dissolves in water, or HIPS, which dissolves in Limonene).

Once the print is finished, you simply submerge the object in the appropriate solvent. The supports dissolve away completely, leaving a perfectly clean surface with no risk of damaging the part. This makes previously "unprintable" geometries achievable.

Understanding the Trade-offs and Challenges

The benefits of dual extrusion do not come without costs. It introduces a higher level of complexity that you must be prepared to manage.

Increased Complexity and Calibration

A dual extruder system has twice the potential points of failure. You must precisely calibrate the nozzle offsets in both the vertical (Z) and horizontal (X/Y) planes.

If the nozzles are not perfectly aligned, you will see gaps or misaligned layers between the two materials, compromising the quality of your print.

Oozing and Cross-Contamination

The inactive nozzle remains hot and can slowly ooze molten plastic onto the print, leading to color bleeding or blemishes.

Most slicers combat this by printing a prime tower or ooze shield alongside the model. This ensures the nozzle is primed and clean before it begins printing, but it also increases print time and wastes a significant amount of filament.

Higher Cost and Maintenance

Printers equipped with dual extruders are typically more expensive than their single-extruder counterparts.

Furthermore, you have two hotends, two nozzles, and two filament paths to maintain and troubleshoot. This doubles the chance of encountering issues like clogs and requires more effort to keep the machine running reliably.

Is a Dual Extruder Right for You?

The decision to invest in a dual extruder system depends entirely on your printing goals.

- If your primary focus is functional prototypes with complex geometry: A dual extruder is a powerful, almost essential, tool for leveraging soluble supports to achieve clean and intricate parts.

- If your primary focus is creating multi-color aesthetic models: A dual extruder offers significant convenience, but a single extruder with manual filament changes is a perfectly viable and much lower-cost alternative.

- If you are a beginner focused on learning the basics: Start with a single extruder. Master the fundamentals of 3D printing first before introducing the added complexity and calibration challenges of a dual extruder system.

Ultimately, choosing a dual extruder is a decision to trade simplicity for a significant expansion in your printer's functional capabilities.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Multi-Color Printing | Automated two-color prints without manual filament swaps |

| Multi-Material Printing | Combine rigid and flexible materials in a single part |

| Soluble Supports | Dissolvable supports enable complex geometries with clean results |

| Functional Versatility | Transform your printer into a multi-purpose fabrication tool |

Ready to elevate your 3D printing capabilities? A dual extruder system can revolutionize your prototyping and production by enabling complex multi-material prints and soluble supports. At KINTEK, we specialize in providing advanced lab equipment, including 3D printing solutions, to meet the demanding needs of research and development laboratories. Let our experts help you integrate the right technology for your projects. Contact us today to discuss your specific requirements and discover how KINTEK can support your innovation!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Customizable XRD Sample Holders for Diverse Research Applications

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- What is the main purpose of vulcanization? Transform Rubber into a Durable, Elastic Material

- What is the process of making rubber sheets? From Raw Rubber to Engineered Performance

- What are the disadvantages of screw extrusion? High Costs and Complexity Explained

- What is the blown film technique? A Guide to High-Strength Plastic Film Production

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?

- What is the difference between single screw and twin screw? Choose the Right Extruder for Your Process

- What is an internal mixer? A Guide to High-Volume Rubber & Plastic Compounding

- What is the process of extrusion blowing? A Guide to Efficient Hollow Plastic Part Production