The primary advantages of hydraulic pressure are its ability to generate immense force from a simple design, its operational efficiency, and its built-in safety features. Hydraulic systems use an incompressible fluid to multiply a small initial force into a much larger output force, allowing for the creation of powerful yet compact and cost-effective machinery.

The core value of a hydraulic system is not just its power, but its ability to deliver immense, precisely controlled force in a simple, reliable, and compact package. This makes it an exceptionally efficient method for tasks requiring significant force multiplication.

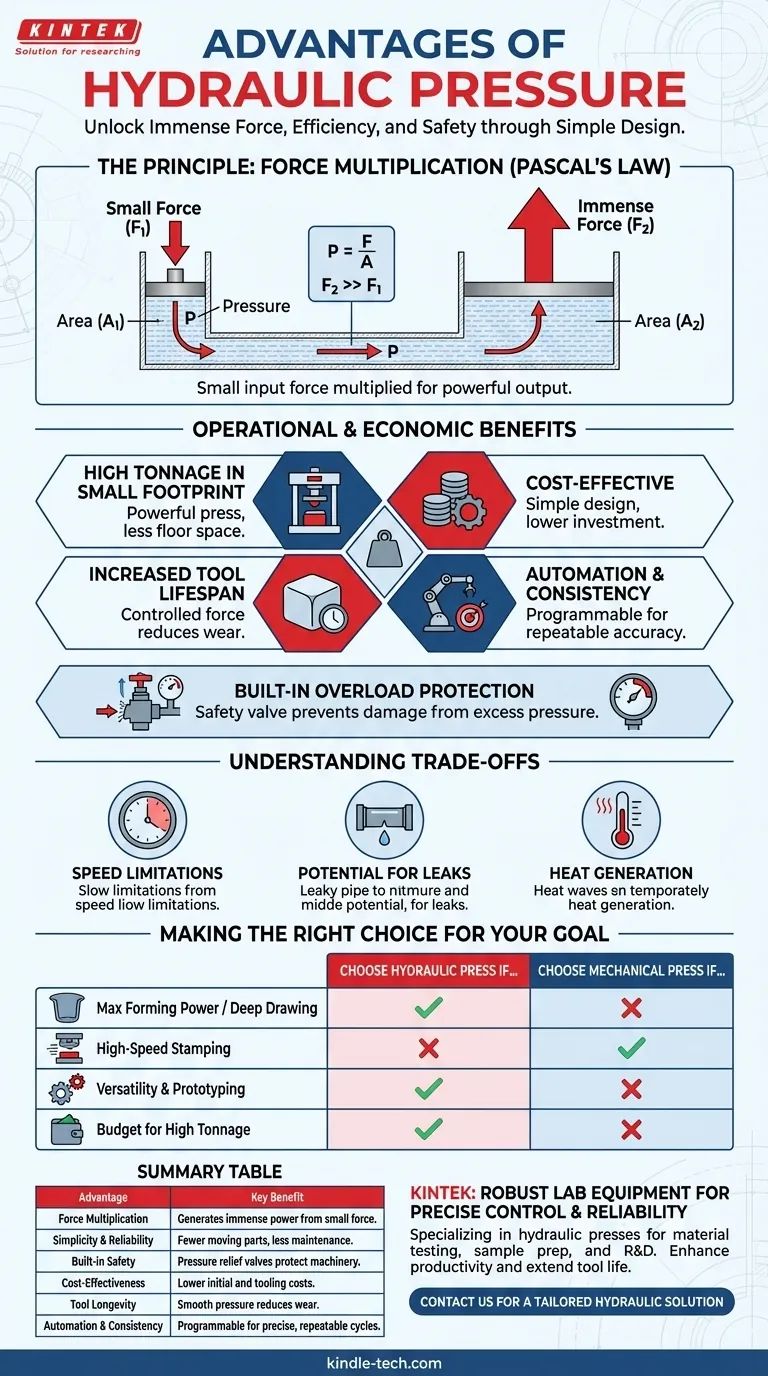

The Principle of Force Multiplication

The fundamental advantages of hydraulics stem from a basic principle of fluid dynamics. Understanding this principle is key to understanding its benefits.

How Pascal's Law Delivers Power

At the heart of every hydraulic system is Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In practice, this means a small amount of force applied to a small piston creates pressure in the fluid. This pressure then acts on a much larger piston, multiplying the initial force significantly.

Simplicity by Design

Hydraulic systems have relatively few moving parts compared to complex mechanical or geared systems. This inherent design simplicity leads to higher reliability, less maintenance, and a longer operational lifespan.

Built-in Overload Protection

Every hydraulic system contains a pressure relief valve. If the pressure in the system exceeds a safe limit (e.g., from a jammed part or an overloaded operation), this valve automatically opens to release the pressure, preventing catastrophic damage to the machine and its tools.

Operational and Economic Advantages

The physical principles of hydraulics translate directly into significant real-world benefits for businesses and operators.

High Tonnage in a Small Footprint

Because they multiply force so effectively, hydraulic presses can generate extremely high tonnage (the maximum force they can exert) while occupying significantly less floor space than a mechanical press of equivalent power.

Cost-Effectiveness

The simple design reduces manufacturing complexity, leading to lower initial and ongoing production costs. With fewer components and a less complex mold or die structure required, both the capital investment and tooling costs are often lower.

Increased Tool Lifespan

Hydraulic force is delivered smoothly and consistently, without the harsh impact and vibration characteristic of mechanical presses. This controlled application of pressure reduces shock and wear, extending the life of expensive dies and tools.

Automation and Consistency

Modern hydraulic presses can be programmed to operate autonomously. This improves workflow by freeing up technicians and ensures superior accuracy and consistency, as the machine precisely repeats the same pressure and cycle every time.

Understanding the Trade-offs

While powerful, hydraulic systems are not the ideal solution for every application. Objectivity requires acknowledging their limitations.

Speed Limitations

For very high-speed, repetitive tasks like stamping small metal parts, a mechanical press can often achieve a faster cycle time (strokes per minute) than a hydraulic press.

Potential for Leaks

Because the systems rely on contained fluid under high pressure, there is always a risk of leaks. A leaking seal can create a mess, pose a slip hazard, and lead to a loss of system pressure and performance.

Heat Generation

The movement of hydraulic fluid under pressure generates heat. In applications with continuous, rapid cycling, an external cooling system (heat exchanger) may be required to prevent the fluid from overheating and degrading.

Making the Right Choice for Your Goal

Selecting the right technology depends entirely on your specific operational needs.

- If your primary focus is maximum forming power or deep drawing: A hydraulic press is the ideal choice due to its ability to deliver constant force throughout the entire stroke.

- If your primary focus is high-speed stamping of simple parts: A mechanical press may offer a better return on investment due to its higher cycle speeds.

- If your primary focus is versatility and prototyping: The precise control over pressure and stroke length makes a hydraulic press highly adaptable for varied tasks.

- If your primary focus is budget for a high-tonnage application: A hydraulic press almost always provides more force for less initial capital investment than a mechanical alternative.

Ultimately, harnessing hydraulic pressure allows you to accomplish an immense amount of work with elegant efficiency.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Force Multiplication | Generates immense power from a small initial force using Pascal's Law. |

| Simplicity & Reliability | Fewer moving parts for less maintenance and a longer lifespan. |

| Built-in Safety | Pressure relief valves prevent overload and protect machinery. |

| Cost-Effectiveness | Lower initial and tooling costs due to simple design. |

| Tool Longevity | Smooth, consistent pressure application reduces wear on dies and tools. |

| Automation & Consistency | Programmable for precise, repeatable cycles and improved workflow. |

Ready to harness the power and efficiency of hydraulic systems for your laboratory or production needs?

At KINTEK, we specialize in providing robust lab equipment, including hydraulic presses, designed to deliver the precise force control, reliability, and cost-effectiveness your operations demand. Whether you're involved in material testing, sample preparation, or R&D prototyping, our solutions are engineered to enhance your productivity and extend the life of your valuable tools.

Contact us today using the form below to discuss how a KINTEK hydraulic solution can be tailored to your specific application. Let our experts help you achieve superior results with equipment you can trust.

Visual Guide

Related Products

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Ball Press Mold for Lab

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Variable Speed Peristaltic Pump

- Assemble Lab Cylindrical Press Mold

People Also Ask

- What is the function of a laboratory hydraulic press in Diamond/Ti composite preparation? Ensuring Atomic Bonding

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- How does a hydraulic hot press machine work? Unlock Precision in Material Bonding and Forming

- What is a hydraulic hot press machine? A Guide to Force and Heat for Material Transformation