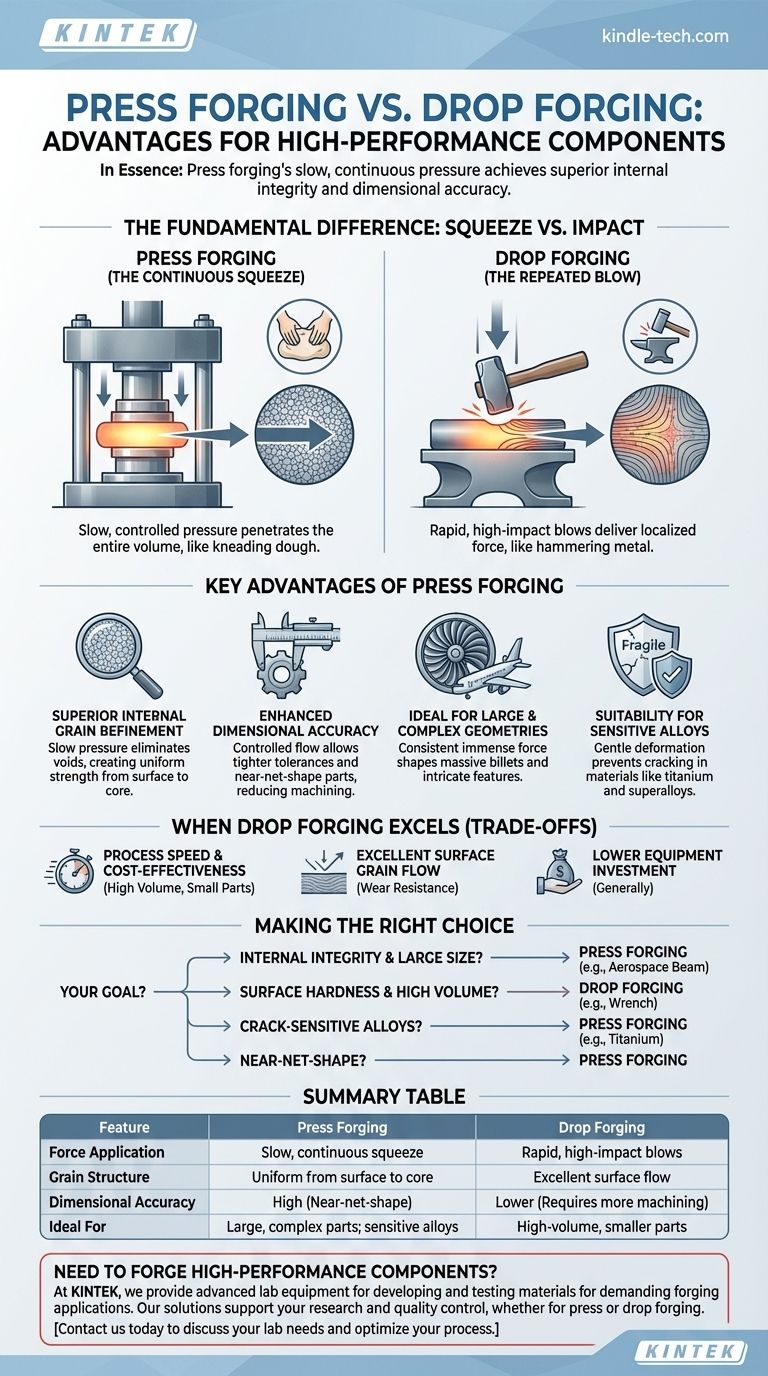

In essence, press forging’s primary advantage over drop forging is its use of slow, continuous pressure to achieve a more uniform grain structure and dimensional accuracy throughout the entire workpiece. This deep, controlled deformation makes it superior for large, complex components and sensitive high-performance alloys where internal integrity is the highest priority.

The choice between press forging and drop forging isn't a matter of which is universally "better," but which is strategically appropriate for the part's size, material, and performance requirements. Press forging excels at creating deep, uniform strength, while drop forging is a powerful, often more economical method for producing parts with exceptional surface strength.

The Fundamental Difference: Squeeze vs. Impact

To understand their respective advantages, you must first grasp their fundamentally different mechanisms. The way force is applied to the metal billet dictates the final properties of the component.

How Press Forging Works: The Continuous Squeeze

Press forging uses a hydraulic or mechanical press to apply slow, controlled, and sustained pressure to the workpiece. Instead of a sharp blow, the die closes on the metal and squeezes it into shape.

This action is more akin to kneading dough, where the force penetrates deep into the center of the material, working the entire volume consistently.

How Drop Forging Works: The Repeated Blow

Drop forging, also known as hammer forging, uses a hammer that is raised and then dropped or propelled onto the workpiece. The process involves a series of rapid, high-impact blows that deform the metal.

This force is intense but localized near the surface. Think of pounding a piece of metal with a hammer; the energy transfer is immediate and concentrated at the point of impact.

Key Advantages of Press Forging

The slow, squeezing action of press forging delivers distinct metallurgical and dimensional benefits, especially for demanding applications.

Superior Internal Grain Refinement

Because the pressure is applied slowly, it has time to penetrate the full cross-section of the workpiece. This results in a highly uniform and refined grain structure from the surface to the core.

This deep deformation eliminates internal voids and improves mechanical properties like fatigue resistance and toughness throughout the entire part, not just at the surface.

Enhanced Dimensional Accuracy

The controlled nature of a forging press allows for exceptional dimensional accuracy and the ability to hold tighter tolerances. The slow closure of the die ensures the metal flows predictably and fills the die cavity completely.

This often reduces the need for extensive post-forge machining, saving time and material costs. This is a key factor in producing "net-shape" or "near-net-shape" parts.

Ideal for Large and Complex Geometries

Press forging is the undisputed method for producing very large components, such as turbine discs, large structural airframe components, and pressure vessel parts.

A hydraulic press can exert immense force consistently over a long stroke, which is necessary to deform massive metal billets and ensure the material flows into complex geometric features without premature cooling.

Suitability for Sensitive Alloys

High-strength, high-temperature alloys like titanium and nickel-based superalloys can be sensitive to the rapid strain rates of drop forging, which can lead to cracking.

The slow, controlled deformation of press forging is far less harsh on these materials, allowing them to be shaped without compromising their structural integrity.

Understanding the Trade-offs: When Drop Forging Excels

No process is superior in all situations. Acknowledging the strengths of drop forging is critical to making an informed decision.

Process Speed and Cost-Effectiveness

For smaller to medium-sized parts produced in high volumes, drop forging is typically much faster. The cycle time of repeated hammer blows is significantly shorter than the single, slow stroke of a press.

This speed translates directly into lower manufacturing costs per unit for components like hand tools, automotive connecting rods, and various hardware fittings.

Excellent Surface Grain Flow

While press forging creates uniform internal strength, the repeated impacts of drop forging create an exceptionally strong and favorable grain flow that follows the contours of the part's surface.

This provides outstanding wear resistance and surface toughness, which can be a primary requirement for certain applications.

Lower Equipment Investment (Generally)

While massive forging presses represent a significant capital investment, the machinery for drop forging can sometimes be less complex and costly, particularly for standard, open-die operations. This can lower the barrier to entry for producing certain types of forged parts.

Making the Right Choice for Your Application

Your final decision must be driven by the specific engineering and economic goals of your project.

- If your primary focus is the internal structural integrity of a large or critical component (e.g., an aerospace landing gear beam): Press forging is the necessary choice for its deep, uniform grain refinement.

- If your primary focus is the cost-effective production of high-volume parts where surface hardness is key (e.g., wrenches or crankshafts): Drop forging often provides the ideal balance of performance and economy.

- If you are working with crack-sensitive, high-performance materials (e.g., titanium or Inconel): The controlled squeeze of press forging is the safer, more reliable method.

- If your goal is to produce a near-net-shape part to minimize machining: Press forging's superior dimensional control offers a distinct advantage.

Understanding the core mechanism of each process—controlled squeeze versus rapid impact—is the key to selecting the optimal path for your component's performance and budget.

Summary Table:

| Feature | Press Forging | Drop Forging |

|---|---|---|

| Force Application | Slow, continuous squeeze | Rapid, high-impact blows |

| Grain Structure | Uniform from surface to core | Excellent surface flow |

| Dimensional Accuracy | High (Near-net-shape) | Lower (Requires more machining) |

| Ideal For | Large, complex parts; sensitive alloys | High-volume, smaller parts; cost-effectiveness |

Need to forge high-performance components with superior internal integrity?

At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for developing and testing materials for demanding forging applications. Whether your project requires the deep, uniform strength of press forging or the economical production of drop-forged parts, our solutions support your research and quality control.

Let our experts help you select the right equipment to optimize your forging process. Contact us today to discuss your specific laboratory needs and how KINTEK can support your success.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the material of filter press? Why Reinforced Polypropylene is the Industry Standard

- Why is KBr suitable for IR sample preparation? The Key to Clear, Unobstructed Infrared Spectroscopy

- How do ultrasonic cell disruptors or dispersion equipment function during ZIF-8 synthesis? Master Acoustic Cavitation

- Why is deposition technology good? Unlock Atomic-Level Control for Superior Materials

- What does the acronym CVD stand for? Decoding Its Meaning in Medicine and Technology

- Why is a precision laboratory heater essential for the acid-catalyzed hydrolysis of waste paper? Optimize Glucose Yield

- How does mixed melting point work? Confirm Compound Identity with Melting Point Depression

- How long is the annealing process? A Guide to Timing for Perfect Material Properties