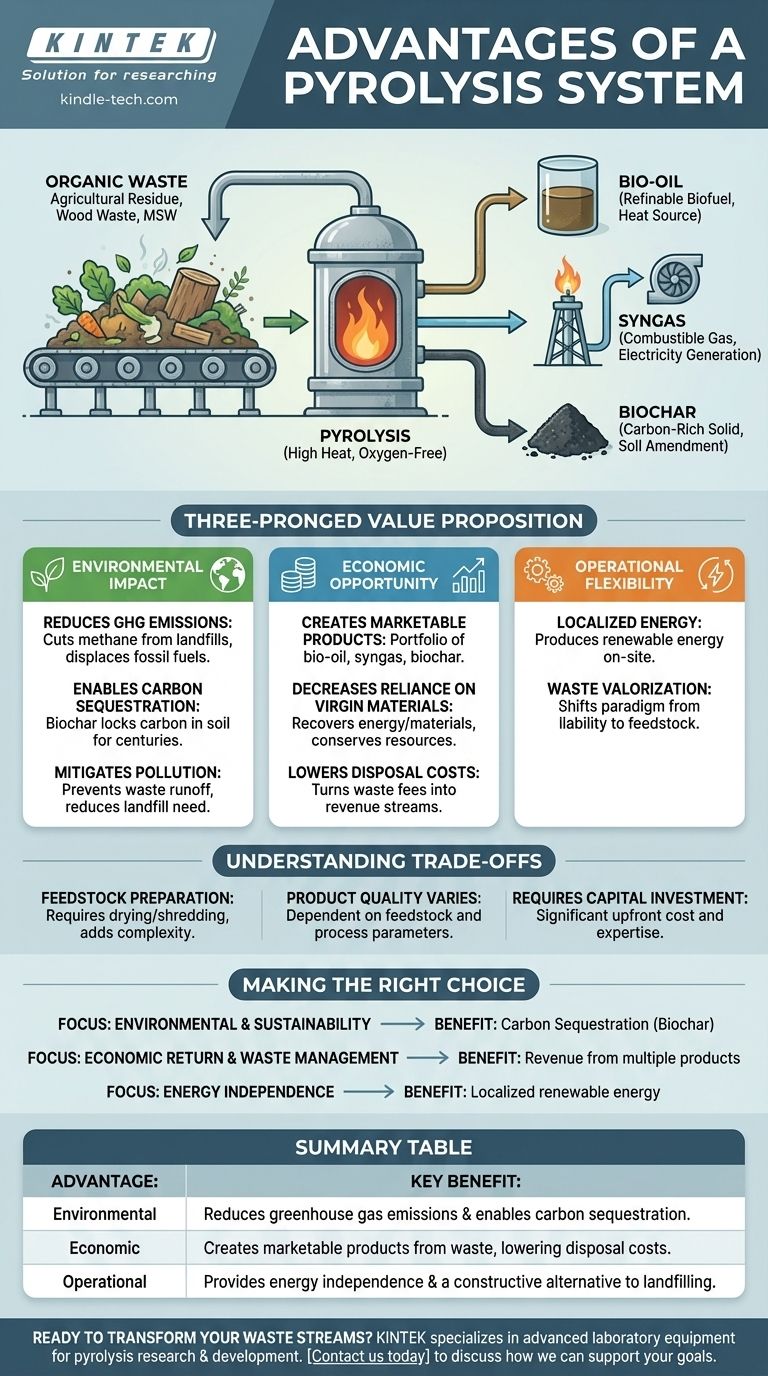

The primary advantage of a pyrolysis system is its ability to convert organic waste into high-value products. Instead of simply disposing of materials like agricultural residue, wood waste, or municipal solid waste, pyrolysis uses high heat in an oxygen-free environment to chemically decompose them. This process creates valuable outputs such as bio-oil, syngas (a combustible gas), and a stable, carbon-rich solid called biochar.

Pyrolysis should not be viewed merely as a waste disposal method, but as a resource valorization technology. It fundamentally shifts the paradigm from treating waste as a liability to be managed into viewing it as a feedstock for producing renewable energy and valuable materials.

A Three-Pronged Value Proposition

The benefits of pyrolysis can be understood across three key areas: environmental protection, economic opportunity, and operational flexibility. Each contributes to its growing role in a circular and bio-based economy.

The Environmental Impact

Pyrolysis offers a direct pathway to address pressing environmental challenges by transforming the carbon cycle of waste materials.

Reduces Greenhouse Gas Emissions By converting organic waste that would otherwise decompose in a landfill and release methane (a potent greenhouse gas), pyrolysis significantly cuts emissions. Furthermore, the fuels it produces can displace fossil fuels, leading to a net reduction in carbon dioxide released into the atmosphere.

Enables Carbon Sequestration The process creates biochar, a highly stable form of charcoal. When added to soil, this biochar effectively locks carbon away for hundreds or even thousands of years. This makes pyrolysis a rare technology that can be carbon-negative, actively removing CO2 from the atmosphere.

Mitigates Land and Water Pollution Properly managing organic waste streams prevents them from polluting local ecosystems. Pyrolysis provides a constructive destination for these materials, reducing the need for landfills and the risk of contaminated runoff.

Transforming Waste into Revenue

Beyond its environmental credentials, pyrolysis presents a compelling economic case by creating new value from low-cost or negative-cost inputs.

Creates Marketable Products

The output of a pyrolysis system is not a single product but a portfolio. Bio-oil can be refined into transportation fuels or used for heat, syngas can be used to generate electricity or power the pyrolysis process itself, and biochar is a valuable soil amendment that improves agricultural yields.

Decreases Reliance on Virgin Materials

By recovering energy and materials from waste, pyrolysis reduces the need to extract virgin fossil fuels and other raw materials. This contributes to resource conservation and can insulate an operation from volatile commodity prices.

Lowers Disposal Costs

For businesses or municipalities that pay significant fees for landfilling or waste disposal, pyrolysis offers a powerful alternative. It turns a consistent operational expense into a potential revenue-generating activity.

Understanding the Trade-offs

While powerful, pyrolysis is not a silver bullet. An objective evaluation requires acknowledging its operational realities.

Feedstock Preparation is Critical

The system's efficiency is highly dependent on the quality of the incoming material. Feedstock often requires drying, shredding, and the removal of contaminants, which adds complexity and cost to the overall operation.

Product Quality Can Vary

The exact composition and quality of the bio-oil, gas, and biochar depend heavily on the type of feedstock used and the precise operating parameters (temperature, heating rate). Achieving a consistent, high-grade product requires significant process control and expertise.

Requires Capital Investment

Pyrolysis facilities are industrial installations that demand significant upfront capital investment and skilled operators. The economic viability must be carefully assessed based on feedstock availability, product markets, and local regulations.

Making the Right Choice for Your Goal

The decision to implement a pyrolysis system should be driven by a clear primary objective.

- If your primary focus is environmental impact and sustainability: The unmatched advantage is its ability to perform carbon sequestration through biochar production, directly addressing climate change.

- If your primary focus is economic return and waste management: The key benefit is the conversion of disposal costs into multiple revenue streams from bio-oil, syngas, and biochar.

- If your primary focus is energy independence and security: The ability to produce localized, renewable energy from readily available waste streams is the system's most compelling feature.

Ultimately, pyrolysis provides a sophisticated framework for transforming environmental liabilities into valuable economic assets.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Environmental | Reduces greenhouse gas emissions and enables carbon sequestration with biochar. |

| Economic | Creates marketable products (bio-oil, syngas, biochar) from waste, lowering disposal costs. |

| Operational | Provides energy independence and a constructive alternative to landfilling. |

Ready to transform your waste streams into valuable assets?

KINTEK specializes in advanced laboratory equipment and consumables, providing the precise tools needed for pyrolysis research and development. Whether you are developing new processes, analyzing bio-oil, or testing biochar properties, our solutions help you achieve accurate and reliable results.

Contact us today to discuss how our equipment can support your pyrolysis projects and contribute to your sustainability and revenue goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the different types of pyrolysis machines? Choose the Right System for Your Output