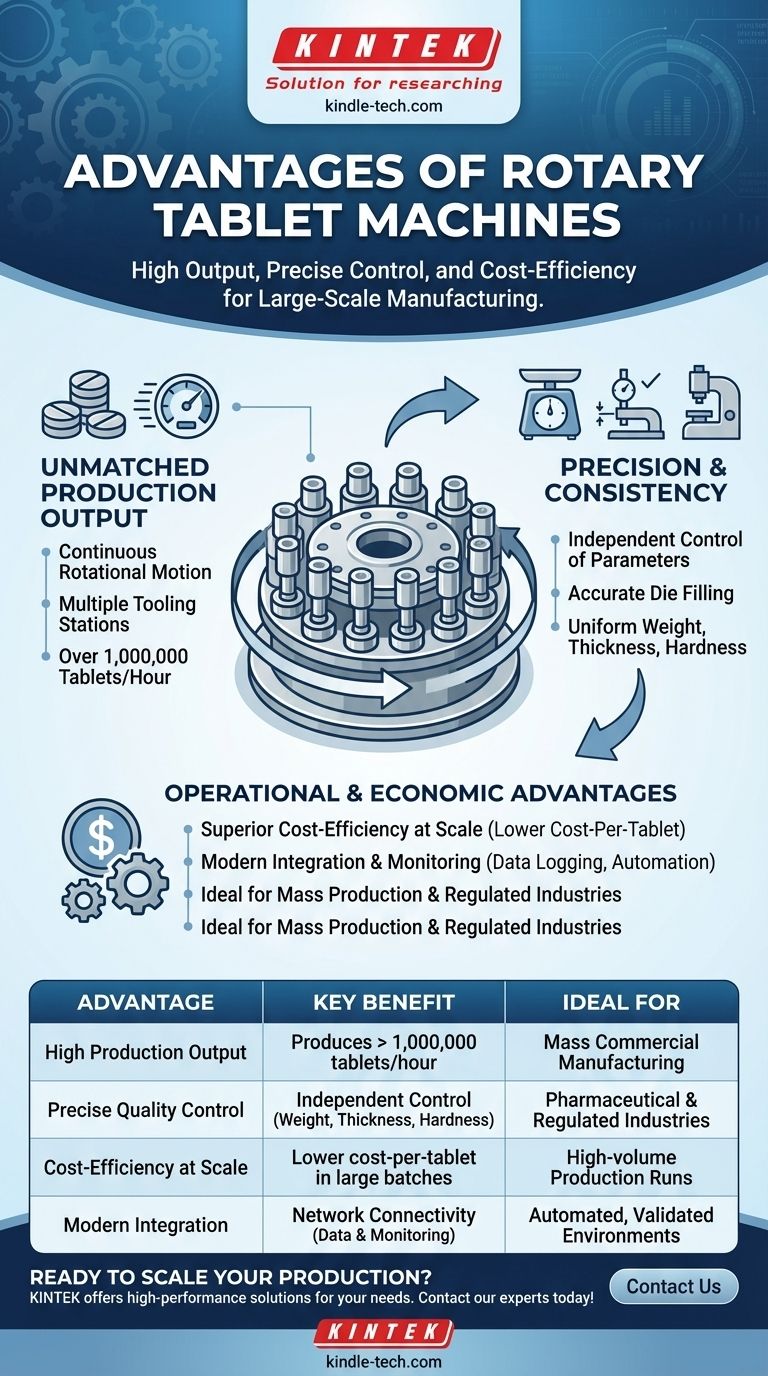

In short, the primary advantages of a rotary tablet press are its exceptionally high production output, precise control over tablet quality, and superior cost-efficiency for large-scale manufacturing. This is achieved through a continuous rotational design with multiple tooling stations, which allows for the simultaneous production of many tablets with remarkable consistency in weight, thickness, and hardness.

The true value of a rotary tablet press lies not just in its speed, but in its ability to combine massive output with the repeatable precision required for modern industrial and pharmaceutical production. It transforms tablet manufacturing from a low-volume, intermittent process into a continuous, highly controlled, and cost-effective operation.

The Core Principle: How Rotary Presses Achieve Superior Output

The fundamental advantage of a rotary press stems from its design. Unlike a single-punch press where one set of tools performs all actions sequentially, a rotary press uses a completely different, continuous-motion paradigm.

Continuous Rotational Motion

A rotary tablet press features a large rotating turret that holds numerous sets of dies and punches.

This turret spins continuously, moving each die and punch set through the various stages of the tablet compression cycle—die filling, compression, and tablet ejection—simultaneously.

Multiple Tooling Stations

Because the press has many "stations" (a die with its upper and lower punch), it produces multiple tablets with every single rotation of the turret.

This multi-station design is the direct mechanism responsible for its immense production capacity.

Unmatched Production Capacity

The result is a production speed that is orders of magnitude greater than other methods.

Modern rotary presses can easily produce hundreds of thousands and even over 1,000,000 tablets per hour, making them the industry standard for any form of mass production.

Precision and Consistency: The Hallmarks of Quality

While speed is a major benefit, the ability to maintain strict quality control at that speed is what makes rotary presses indispensable, especially in regulated industries like pharmaceuticals.

Independent Control of Tablet Parameters

Rotary presses provide operators with the ability to independently and accurately control critical tablet attributes.

This includes fine-tuning tablet weight (dosage), thickness, and hardness (dissolution rate and durability). This level of control is essential for meeting product specifications and ensuring batch-to-batch uniformity.

Accurate and Consistent Die Filling

The design ensures that as the turret rotates, each die cavity is filled with a precise and consistent volume of powder.

This consistency in filling is the foundation for achieving uniform tablet weight, which is a critical quality attribute for dosage accuracy.

Understanding the Operational and Economic Advantages

The technical capabilities of a rotary press translate directly into significant operational and financial benefits, particularly as production volume increases.

Superior Cost-Efficiency at Scale

While the initial investment in a rotary press is higher than a single-punch press, its high output dramatically lowers the cost-per-tablet in large production runs.

For any commercial-scale operation, the efficiency gains and reduced labor requirements per unit make it the far more economical choice.

Modern Integration and Monitoring

Many modern rotary presses can be interfaced with in-house network systems.

This allows for remote process monitoring, data logging, and integration into modern automated manufacturing environments, which is crucial for process validation and quality assurance.

Key Considerations and Trade-offs

It is important to note that rotary presses are complex machines requiring significant capital investment and skilled operators for setup and maintenance.

Their primary drawback is that they are not well-suited for very small batches or early-stage research and development, where a simpler, less expensive single-punch press is often more practical.

Making the Right Choice for Your Production Needs

Ultimately, the decision to use a rotary tablet press must align with your specific production goals and scale.

- If your primary focus is mass commercial production: The unparalleled speed and low cost-per-unit of a rotary press make it the only viable choice.

- If your primary focus is ensuring strict quality and dosage uniformity: The precise, independent controls for weight, thickness, and hardness are essential for meeting regulatory and quality standards.

- If your primary focus is R&D or producing small, developmental batches: A less complex single-punch press is likely a more practical and cost-effective solution.

Choosing the right compression technology is about matching the equipment's capabilities to the demands of your specific manufacturing operation.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| High Production Output | Produces over 1,000,000 tablets/hour | Mass commercial manufacturing |

| Precise Quality Control | Independent control of weight, thickness, hardness | Pharmaceutical & regulated industries |

| Cost-Efficiency at Scale | Lower cost-per-tablet in large batches | High-volume production runs |

| Modern Integration | Network connectivity for data logging & monitoring | Automated, validated manufacturing environments |

Ready to scale your tablet production with precision and efficiency? KINTEK specializes in high-performance lab equipment and consumables, including rotary tablet presses designed for laboratory and industrial needs. Our solutions help you achieve consistent quality and high output for your specific manufacturing requirements. Contact our experts today to find the perfect press for your operation!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- What do you press pills with? The Essential Guide to Tablet Press Machines

- How fast is the rotary tablet press? Unlock Peak Production Speeds for Your Tablets

- What is the use of a biomass pellet machine? Turn Waste into Fuel, Feed, and Bedding

- How does a flat die pellet mill work? A Complete Guide to Small-Scale Pellet Production

- What is the advantage of a single punch tablet machine? Ideal for Low-Waste R&D and Formulation Testing

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- What are advantages of single punch tablet press machine? Maximize R&D Efficiency with Minimal Material