At its core, the primary advantage of a modern induction furnace is its ability to provide an exceptionally clean, fast, and precisely controlled melting process. Unlike traditional methods, it uses electromagnetic induction to generate heat directly within the metal itself, leading to higher efficiency, superior metallurgical quality, and a significantly improved working environment.

The fundamental shift from external combustion or electric arcs to internal, induction-based heating is what drives every major benefit. This shift gives you unparalleled control over temperature and metal purity, which in turn reduces waste, lowers operational costs, and improves safety.

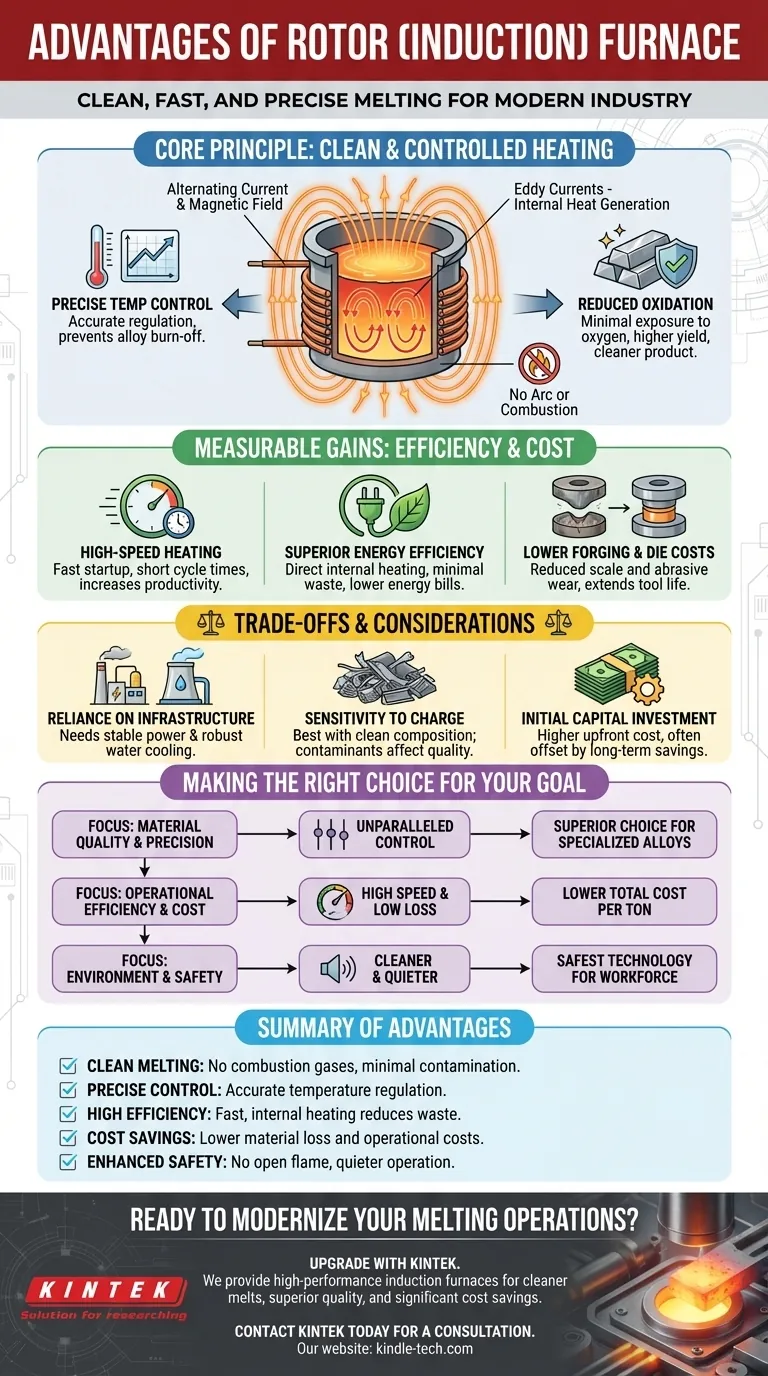

The Core Principle: Clean and Controlled Heating

The most significant advantages stem directly from the underlying technology. An induction furnace operates more like a high-powered, precise instrument than a conventional furnace.

How Induction Works (No Arc or Combustion)

An induction furnace uses a powerful alternating current passed through a copper coil. This creates a strong magnetic field that induces electrical currents (eddy currents) within the metal charge placed inside.

These currents generate rapid and uniform heat throughout the metal due to its own electrical resistance. This process requires no external flame, arc, or heating element, eliminating a primary source of contamination.

The Benefit of Precision Temperature Control

Because the heat is generated internally, the temperature can be regulated with extreme accuracy. This prevents overheating and the subsequent "burn-off" of valuable and expensive alloying elements.

This level of control is critical when working with specialized alloys where the final chemical composition must meet tight specifications.

Reduced Oxidation and Material Loss

With no combustion gases and a much faster melting process, the molten metal has minimal exposure to oxygen. This dramatically reduces oxidation and decarburization—the loss of carbon from the steel.

The result is a higher yield from your raw materials and a cleaner final product, saving significant costs on both materials and subsequent refining steps.

Measurable Gains in Efficiency and Cost

The operational benefits translate directly into a more favorable economic outcome, impacting everything from energy bills to productivity.

High-Speed Heating and Productivity

Induction furnaces are known for their fast startup times and high melting rates. Heat is generated almost instantly within the charge, leading to much shorter cycle times compared to fuel-fired furnaces. This directly increases production efficiency.

Superior Energy Efficiency

Since the heat is generated directly where it is needed—inside the metal—very little energy is wasted heating the furnace walls or the surrounding atmosphere. This makes induction one of the most energy-efficient melting technologies available.

Lower Forging and Die Costs

The reduced scale and oxidation on the surface of the heated metal means less abrasive wear on forging dies and other tooling. This extends the life of expensive dies and reduces maintenance costs.

Understanding the Trade-offs and Considerations

While highly advantageous, this technology is not without its specific operational requirements and potential limitations.

Reliance on Infrastructure

Induction furnaces require a stable and robust electrical power supply. They are also dependent on a well-maintained water cooling system to protect the high-power copper coils from overheating. Any failure in these systems will halt production.

Sensitivity to Charge Material

The process works best with a charge of a known and relatively clean composition. While robust, performance can be affected by heavily rusted scrap or contaminants that can impact the final chemistry of the melt.

Initial Capital Investment

The initial purchase and installation cost of an induction furnace system, including the necessary power and cooling infrastructure, can be higher than for some traditional furnace types. However, this is often offset by lower long-term operating costs.

Making the Right Choice for Your Goal

Selecting a furnace technology depends entirely on your primary objectives.

- If your primary focus is material quality and precision: The unparalleled temperature control and low-contamination environment of an induction furnace make it the superior choice for producing high-value, specialized alloys.

- If your primary focus is operational efficiency and cost: The combination of high speed, low material loss, and superior energy efficiency results in a lower total cost per ton of melted metal.

- If your primary focus is environmental impact and worker safety: The elimination of combustion byproducts, reduced noise, and integrated safety features make this the cleanest and safest melting technology for your workforce.

Ultimately, adopting an induction furnace is a strategic decision to modernize your melting operations for greater precision, efficiency, and safety.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Clean Melting | No combustion gases; minimal contamination and oxidation. |

| Precise Control | Accurate temperature regulation prevents alloy burn-off. |

| High Efficiency | Fast, internal heating reduces cycle times and energy waste. |

| Cost Savings | Lower material loss, reduced die wear, and operational costs. |

| Enhanced Safety | No open flame; quieter operation and improved workplace safety. |

Ready to Modernize Your Melting Operations with Precision and Efficiency?

Upgrade your lab or foundry with a high-performance induction furnace from KINTEK. We specialize in lab equipment and consumables, providing solutions that deliver cleaner melts, superior metallurgical quality, and significant long-term cost savings. Our experts will help you select the right system to meet your specific goals for quality, efficiency, and safety.

Contact KINTEK today for a consultation and discover how our induction furnaces can transform your metal melting process.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- Can you restore activated carbon? Understanding the Industrial Reactivation Process

- What is the temperature for activated carbon regeneration? Key Ranges from 220°C to 900°C

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the temperature of a carbon regeneration kiln? Mastering the 750-800°C Reactivation Process