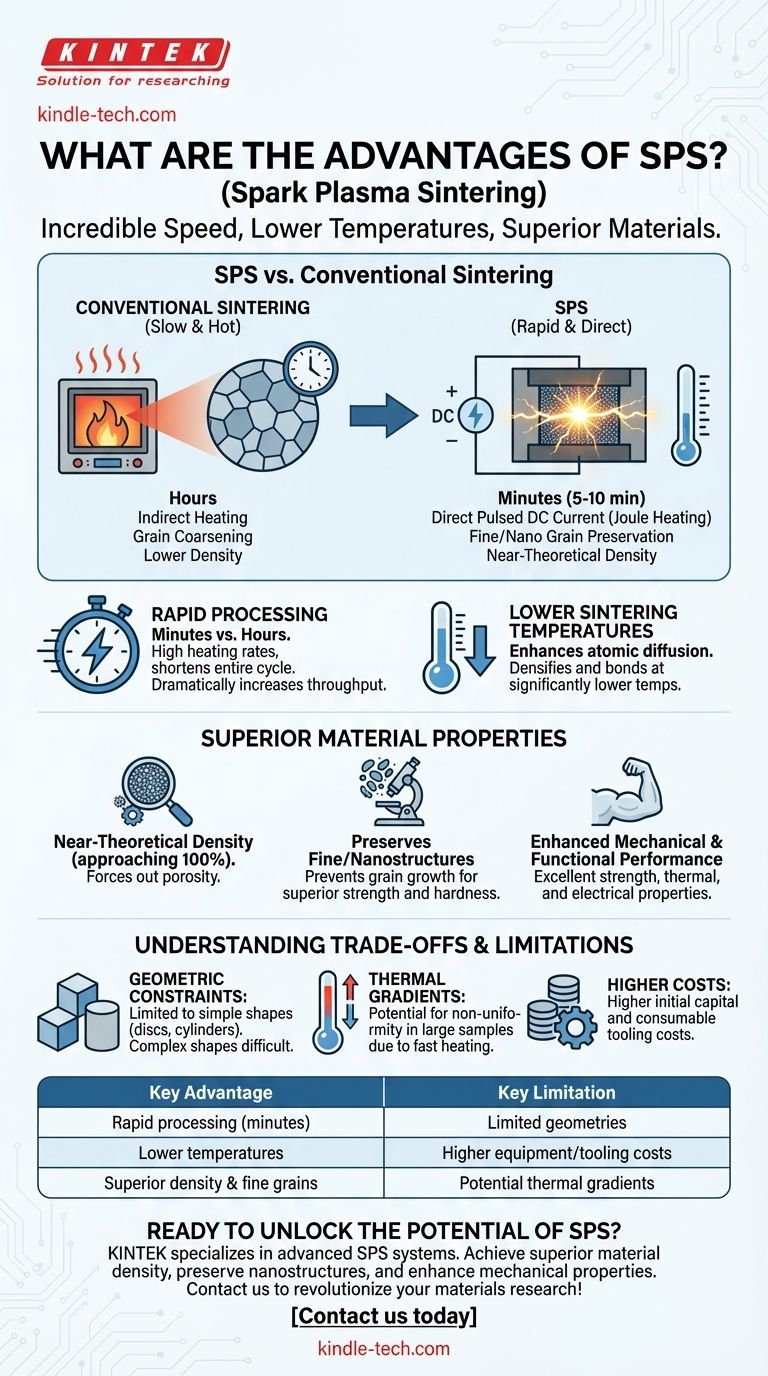

The primary advantages of Spark Plasma Sintering (SPS) are its incredible speed, lower processing temperatures, and its ability to produce materials with superior density and properties compared to conventional methods. By using a pulsed electrical current to directly heat the material, SPS shortens processing times from many hours to mere minutes, fundamentally changing the possibilities for materials science.

Spark Plasma Sintering is not just an incremental improvement over traditional sintering; it is a transformative technology. Its core advantage lies in using rapid, direct electrical heating to achieve full material densification while preventing the microstructural damage—like unwanted grain growth—that plagues slower, high-temperature methods.

How SPS Redefines Material Processing

The advantages of SPS stem directly from its unique heating mechanism, which is fundamentally different from the slow, indirect heating of a conventional furnace.

The Role of Pulsed Current and Joule Heating

Traditional furnaces heat a chamber, which then slowly heats the mold and, finally, the material powder inside. This process is slow and inefficient.

SPS, by contrast, passes a high-power pulsed DC current directly through the conductive graphite mold and, in some cases, the material powder itself. This generates instantaneous, uniform heat via Joule heating, the same principle that makes a toaster element glow.

Unprecedented Heating and Cooling Rates

The direct nature of this heating allows for extremely high heating rates, often hundreds of degrees Celsius per minute. This shortens the entire sintering cycle to as little as 5 to 10 minutes, compared to the several hours required for conventional sintering. This rapid cycle dramatically increases laboratory or production throughput.

Lower Sintering Temperatures

The pulsed current is believed to generate spark discharges between powder particles, cleaning their surfaces and enhancing atomic diffusion. This effect, combined with the applied pressure, allows materials to densify and bond at significantly lower temperatures than required in traditional methods.

The Impact on Final Material Properties

The speed and low temperatures of the SPS process are not just about efficiency; they are critical for creating higher-performing materials.

Achieving Near-Theoretical Density

The combination of mechanical pressure and enhanced particle bonding forces out virtually all porosity between the powder grains. This allows SPS to consistently produce materials with very high density, often approaching 100% of the theoretical maximum. High density is crucial for superior mechanical and functional properties.

Preserving Fine Grain Structures

In conventional sintering, the long exposure to high temperatures causes small material grains to merge and grow larger, a process called grain coarsening. This degrades a material's strength and hardness.

Because the SPS process is so fast, it consolidates the powder before the grains have time to grow. This allows it to preserve fine-grained or even nanostructured microstructures in the final dense part, which is key to its enhanced performance.

Enhanced Mechanical and Functional Performance

The resulting combination of high density and fine grain size gives SPS-processed materials excellent mechanical properties, including superior strength and hardness. This unique microstructure also leads to enhanced thermal and electrical properties, making SPS ideal for creating advanced functional materials.

Understanding the Trade-offs and Limitations

While powerful, SPS is not a universal solution. Its primary limitations are related to geometry, scale, and cost.

Geometric and Tooling Constraints

The process is typically limited to producing parts with simple geometries, such as discs, cylinders, and rectangular blocks, that can be formed in a graphite die. Complex shapes are difficult and often impossible to produce directly.

Potential for Thermal Gradients

In larger samples or materials with low thermal conductivity, the extremely fast heating rates can create temperature differences between the surface and the core. This can lead to non-uniform density or microstructure if not managed properly.

Equipment and Operational Costs

The initial capital investment for an SPS system is significantly higher than for a standard high-temperature furnace. Furthermore, the graphite dies and punches are consumable items that degrade with use, adding to the operational cost of the process.

Deciding if SPS is Right for Your Application

Choosing between SPS and conventional methods depends entirely on your end goal.

- If your primary focus is developing novel materials or preserving delicate nanostructures: SPS is an unparalleled tool due to its ability to consolidate powders at low temperatures and with minimal processing time.

- If your primary focus is producing high-performance components with maximum density and strength: The ability of SPS to create fine-grained, fully dense parts makes it a superior choice over conventional sintering.

- If your primary focus is mass-producing large or geometrically complex parts at the lowest cost: The constraints and equipment costs of SPS may make traditional methods like casting or hot pressing more suitable.

By understanding its unique mechanism and trade-offs, you can leverage SPS to create materials that are simply not achievable with conventional techniques.

Summary Table:

| Key Advantage | Key Limitation |

|---|---|

| Rapid processing (minutes vs. hours) | Limited to simple geometries |

| Lower sintering temperatures | Higher equipment and tooling costs |

| Superior density and fine grain structures | Potential for thermal gradients in large samples |

Ready to unlock the potential of Spark Plasma Sintering for your lab?

KINTEK specializes in providing advanced lab equipment, including SPS systems, to help you achieve superior material density, preserve nanostructures, and enhance mechanical properties. Whether you're developing novel materials or producing high-performance components, our expertise ensures you get the most out of this transformative technology.

Contact us today to discuss how SPS can revolutionize your materials research and production!

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- How does a carbon powder bed facilitate near-net-shape sintering? Master Complex Ti2AlC Gear Production via SPS

- What is sps metal? Unlocking High-Performance Materials with Spark Plasma Sintering

- How hot isostatic press works? A Guide to Eliminating Porosity and Enhancing Part Performance

- Why must LiTa2PO8 (LTPO) pellets undergo annealing after hot-pressing? Ensure Pure Ionic Conductivity

- What role does a vacuum hot pressing sintering furnace play in AZ31 densification? Achieve Near-Theoretical Density

- Why is high mechanical pressure required in vacuum hot pressing Al/CNT composites? Unlock Maximum Density Today

- What key functions does a vacuum hot press sintering furnace perform in the fabrication of 30% SiCp/2024Al composites?

- How does the programmable temperature control of a vacuum hot press furnace benefit the reactive synthesis of TiAl?