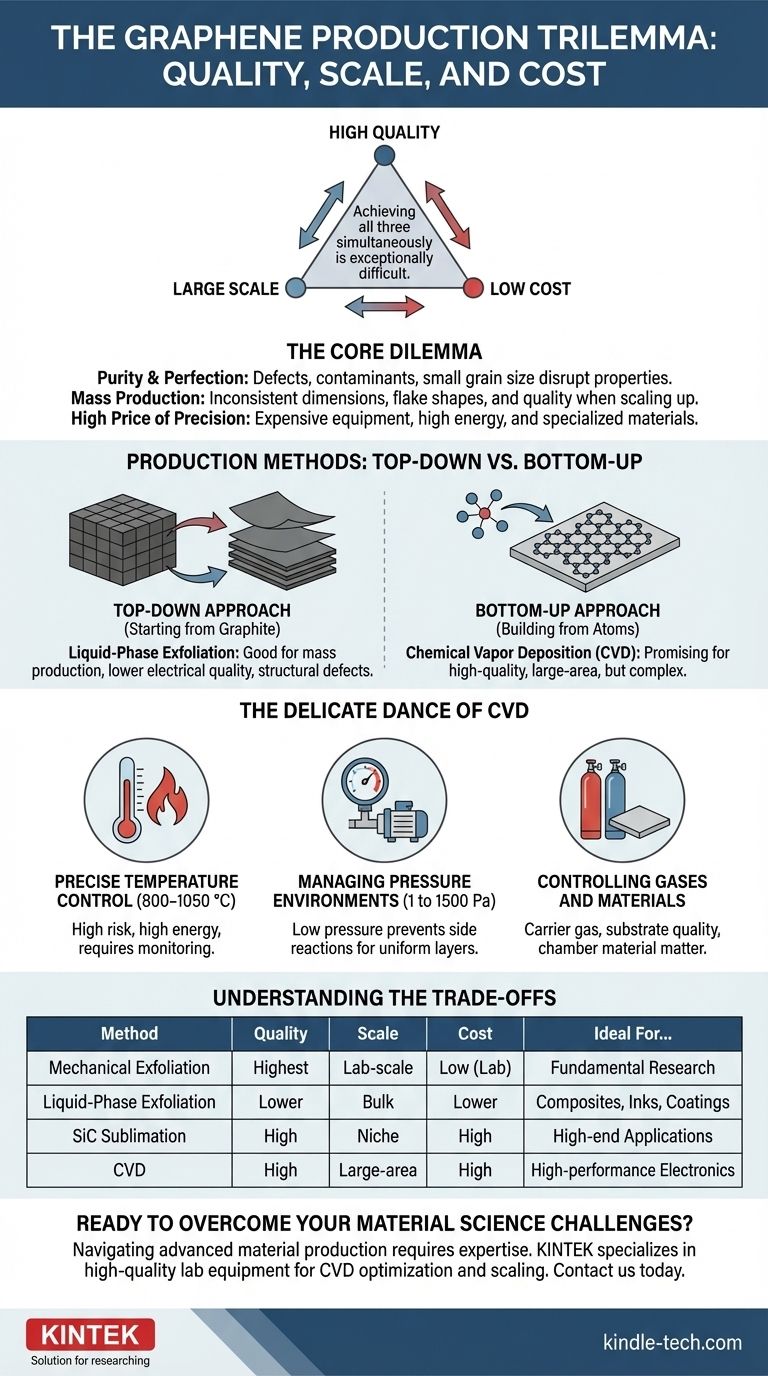

At its core, the challenge of producing graphene is the immense difficulty of achieving three conflicting goals at once: high quality, large scale, and low cost. While several methods exist, none currently satisfy all three requirements, forcing producers to make significant trade-offs depending on the final application.

The central problem in graphene production is a fundamental conflict between manufacturing methods. Techniques that yield pristine, high-quality graphene are difficult to scale and expensive, while methods capable of mass production often result in material with significant defects and lower performance.

The Core Dilemma: Quality, Scale, and Cost

The promise of graphene relies on its perfect, single-atom-thick lattice structure. Any deviation from this ideal state compromises its remarkable properties. The primary production challenges revolve around maintaining this perfection during manufacturing.

Achieving Purity and Perfection

The quality of graphene is defined by its structural integrity. Defects, contaminants, and small grain size disrupt the flow of electrons and weaken the material. Producing a uniform, single-layer sheet with a large grain size and zero defects is the ultimate goal, but it remains an exceptionally difficult technical hurdle.

The Challenge of Mass Production

Methods that work perfectly in a lab often fail when scaled up for industrial use. Current techniques produce graphene with inconsistent dimensions, flake shapes, and overall quality. True mass production requires a reliable, repeatable process that consistently delivers high-grade material, a goal that has proven elusive.

The High Price of Precision

Even when high-quality graphene can be produced, the cost is often prohibitive. Methods like the sublimation of silicon carbide (SiC) or highly controlled Chemical Vapor Deposition (CVD) require expensive equipment, high energy consumption, and specialized materials, making the resulting graphene too costly for many commercial applications.

Production Methods: "Top-Down" vs. "Bottom-Up"

Graphene production is broadly divided into two strategic approaches, each with its own set of challenges.

The "Top-Down" Approach: Starting from Graphite

This method involves separating layers of graphene from bulk graphite.

Liquid-phase exfoliation is the primary technique here. It is suitable for mass production and can generate large quantities of graphene flakes. However, the process often yields material with lower electrical quality and structural defects, making it unsuitable for high-performance electronics.

The "Bottom-Up" Approach: Building from Atoms

This strategy involves assembling graphene atom-by-atom on a substrate.

Chemical Vapor Deposition (CVD) is the leading "bottom-up" method and is widely considered the most promising technique for producing high-quality, large-area graphene suitable for industrial use. However, its complexity is its main challenge.

The Delicate Dance of Chemical Vapor Deposition (CVD)

While CVD is the most capable method for industrial-scale production, it is a complicated and delicate process that requires extreme precision. Success depends on carefully managing several interdependent physical conditions.

Precise Temperature Control

The CVD process typically operates at very high temperatures, ranging from 800–1050 °C. While higher temperatures can increase reaction rates, they also introduce greater risks, demand more energy, and require careful monitoring to ensure the quality of the graphene layer.

Managing Pressure Environments

Most CVD systems use low pressure (LPCVD), from 1 to 1500 Pa. This low-pressure environment is critical for preventing unwanted side reactions and depositing a more uniform, even layer of graphene across the substrate.

Controlling Gases and Materials

The final quality of the graphene is also highly dependent on other variables. The specific carrier gas used, the quality of the substrate (often copper), and even the material of the reaction chamber itself all play a significant role and must be meticulously controlled.

Understanding the Trade-offs

No single production method is universally superior. The choice is always dictated by the intended application and the acceptable compromises in quality, scale, and cost.

Mechanical Exfoliation

This lab-scale method produces the highest-quality graphene flakes. It is perfect for fundamental research but is completely unsuitable for any form of mass production.

Liquid-Phase Exfoliation

This technique is the workhorse for bulk applications. It is ideal for producing large quantities of graphene for use in composites, inks, and coatings where pristine electrical properties are not the priority.

SiC Sublimation

This process creates high-quality graphene directly on a silicon carbide wafer. However, the extremely high cost of the substrate and the process itself limits its use to niche, high-end applications.

Chemical Vapor Deposition (CVD)

CVD represents the best path toward high-performance, large-area applications like transparent electrodes and advanced electronics. Its primary drawbacks are the process complexity and associated costs.

Making the Right Choice for Your Goal

The optimal production method is defined by your end goal.

- If your primary focus is fundamental research: Mechanical exfoliation remains the gold standard for producing near-perfect samples for scientific study.

- If your primary focus is large-volume industrial composites or inks: Liquid-phase exfoliation provides the necessary scale at a reasonable cost, sacrificing pristine quality.

- If your primary focus is high-performance electronics or large-area films: Chemical Vapor Deposition (CVD) is the only viable path, requiring significant investment in process control and optimization.

Ultimately, bridging the gap between graphene's potential and its widespread adoption depends on mastering the complex interplay between production quality, scale, and cost.

Summary Table:

| Challenge | Key Issue | Common Production Method(s) |

|---|---|---|

| Achieving High Quality | Defects, contaminants, and small grain size compromise properties. | Mechanical Exfoliation, CVD, SiC Sublimation |

| Scaling Up Production | Inconsistent dimensions, flake shapes, and quality when moving from lab to industry. | Liquid-Phase Exfoliation, CVD |

| Reducing Cost | Expensive equipment, high energy use, and specialized materials drive up price. | Liquid-Phase Exfoliation (lower cost, lower quality) |

| Method Selection | Balancing quality, scale, and cost based on the final application. | All methods involve significant trade-offs |

Ready to Overcome Your Material Science Challenges?

Navigating the complexities of advanced material production requires expertise and precision equipment. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to the demanding needs of modern laboratories.

Whether you are optimizing a CVD process for graphene synthesis or scaling up production for industrial applications, our solutions are designed to enhance your research and development, improve process control, and help you achieve more consistent, reliable results.

Contact us today to discuss how KINTEK can support your laboratory's specific needs and help you push the boundaries of material science.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques