Heat treatment furnaces are primarily classified by their heat source, operating temperature range, and the specific metallurgical process they are designed to perform. These classifications are not mutually exclusive; a single furnace is often described using a combination of these factors to define its capabilities and intended use.

The method used to classify a heat treatment furnace directly reflects the core requirements of the metallurgical task it must accomplish. Understanding these categories is essential for matching the right equipment to the desired material properties and process efficiency.

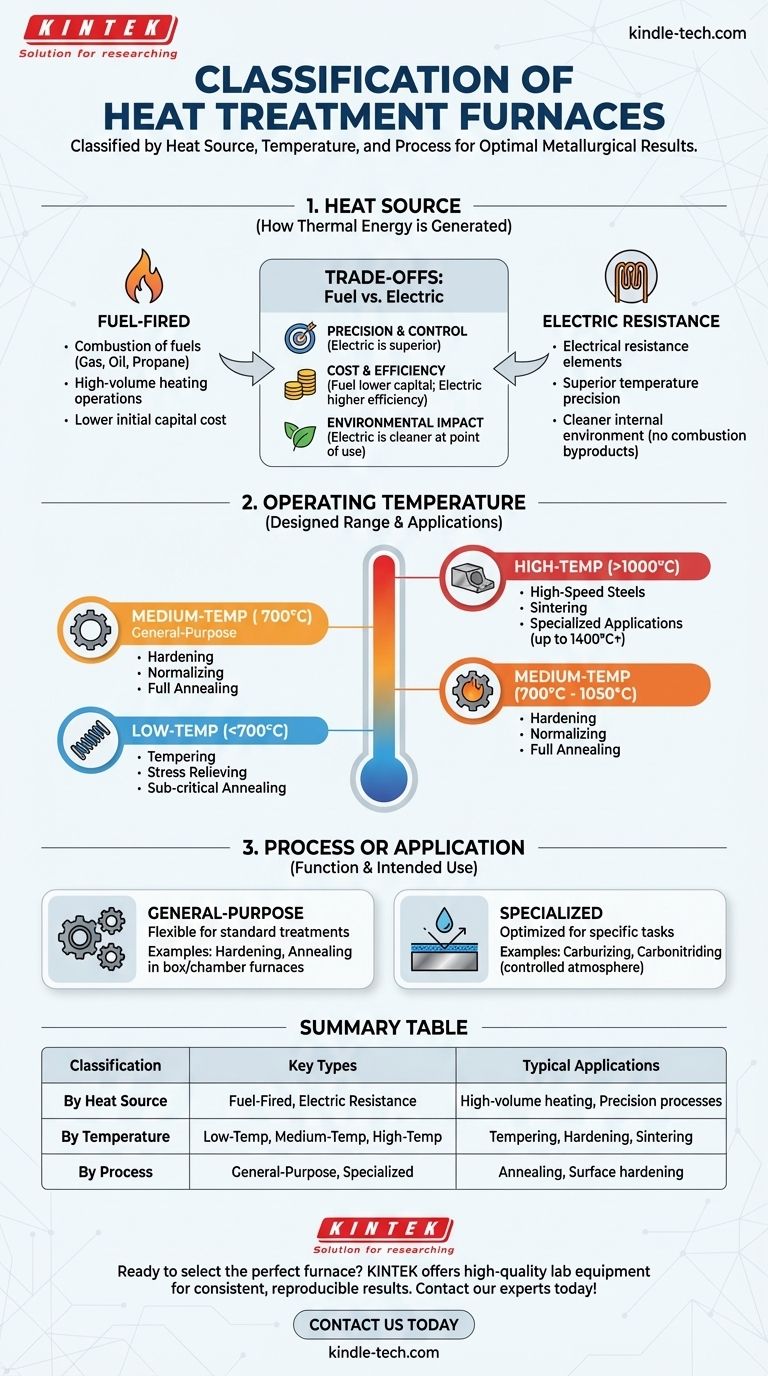

Classification by Heat Source

The most fundamental distinction between furnaces is how they generate thermal energy. This choice impacts temperature control, operating costs, and the internal atmosphere of the furnace.

Fuel-Fired Furnaces

These furnaces generate heat through the combustion of fuels like natural gas, oil, or propane. They are often used for large-scale heating operations where high heat input is required.

Electric Resistance Furnaces

These furnaces use electrical resistance elements to generate heat. They offer more precise temperature control and a cleaner internal environment, as there are no byproducts of combustion.

Classification by Operating Temperature

A furnace's construction and insulation are designed for a specific temperature range, which directly correlates with the types of heat treatment processes it can handle.

Low-Temperature Furnaces (<650°C - 700°C)

This range is used for processes that occur below the critical transformation temperature of steel. Common applications include tempering, stress relieving, and sub-critical annealing.

Medium-Temperature Furnaces (650°C - 1050°C)

Often considered general-purpose furnaces, this is the most common range. It covers critical heat treatments like hardening, normalizing, and full annealing for most carbon and alloy steels.

High-Temperature Furnaces (>1000°C)

These furnaces are built with specialized refractory materials to handle extreme heat. They are required for treating high-speed steels, sintering powdered metals, and other specialized applications that demand temperatures up to 1400°C or higher.

Classification by Process or Application

Furnaces are often designed and named for the specific metallurgical process they are optimized to perform. This classification speaks directly to the furnace's function.

General-Purpose Furnaces

These are typically box or chamber furnaces designed for a wide variety of standard treatments like hardening and annealing, offering flexibility for different jobs.

Specialized Furnaces

Many furnaces are built for one specific task. For example, carburizing or carbonitriding furnaces are designed to operate with controlled carbon-rich atmospheres to modify the surface chemistry of steel components.

Understanding the Trade-offs: Fuel vs. Electric

Choosing between a fuel-fired and an electric furnace involves a clear set of trade-offs that impact both performance and cost.

Precision and Control

Electric furnaces offer superior temperature uniformity and precision. The absence of combustion allows for a more stable and easily controlled internal atmosphere, which is critical for sensitive processes.

Cost and Efficiency

Fuel-fired furnaces often have a lower initial capital cost and can be cheaper to operate in regions with low fuel prices. However, electric furnaces can be more energy-efficient as more of the energy input is converted directly to usable heat.

Environmental Impact

Electric furnaces produce no local emissions, making them a cleaner option at the point of use. In contrast, fuel-fired furnaces release combustion byproducts that must be managed.

Making the Right Choice for Your Goal

Selecting the appropriate furnace requires aligning its classification with your specific metallurgical objective.

- If your primary focus is process precision and a controlled atmosphere: An electric resistance furnace is the superior choice.

- If your primary focus is high-volume heating for general-purpose treatments: A medium-temperature, fuel-fired furnace may be the most cost-effective solution.

- If you are performing a specialized surface treatment like carburizing: You must select a furnace explicitly designed and classified for that process.

Understanding these classifications empowers you to select the precise tool required to achieve consistent and reproducible material properties.

Summary Table:

| Classification | Key Types | Typical Applications |

|---|---|---|

| By Heat Source | Fuel-Fired, Electric Resistance | High-volume heating, Precision processes |

| By Temperature | Low-Temp (<700°C), Medium-Temp (700-1050°C), High-Temp (>1000°C) | Tempering, Hardening, Sintering |

| By Process | General-Purpose, Specialized (e.g., Carburizing) | Annealing, Surface hardening |

Ready to select the perfect heat treatment furnace for your lab? KINTEK specializes in providing high-quality lab equipment and consumables tailored to your specific metallurgical processes. Whether you need the precision of an electric furnace or the cost-effectiveness of a fuel-fired system, our experts will help you achieve consistent, reproducible results. Contact us today to discuss your requirements and enhance your laboratory's capabilities!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer