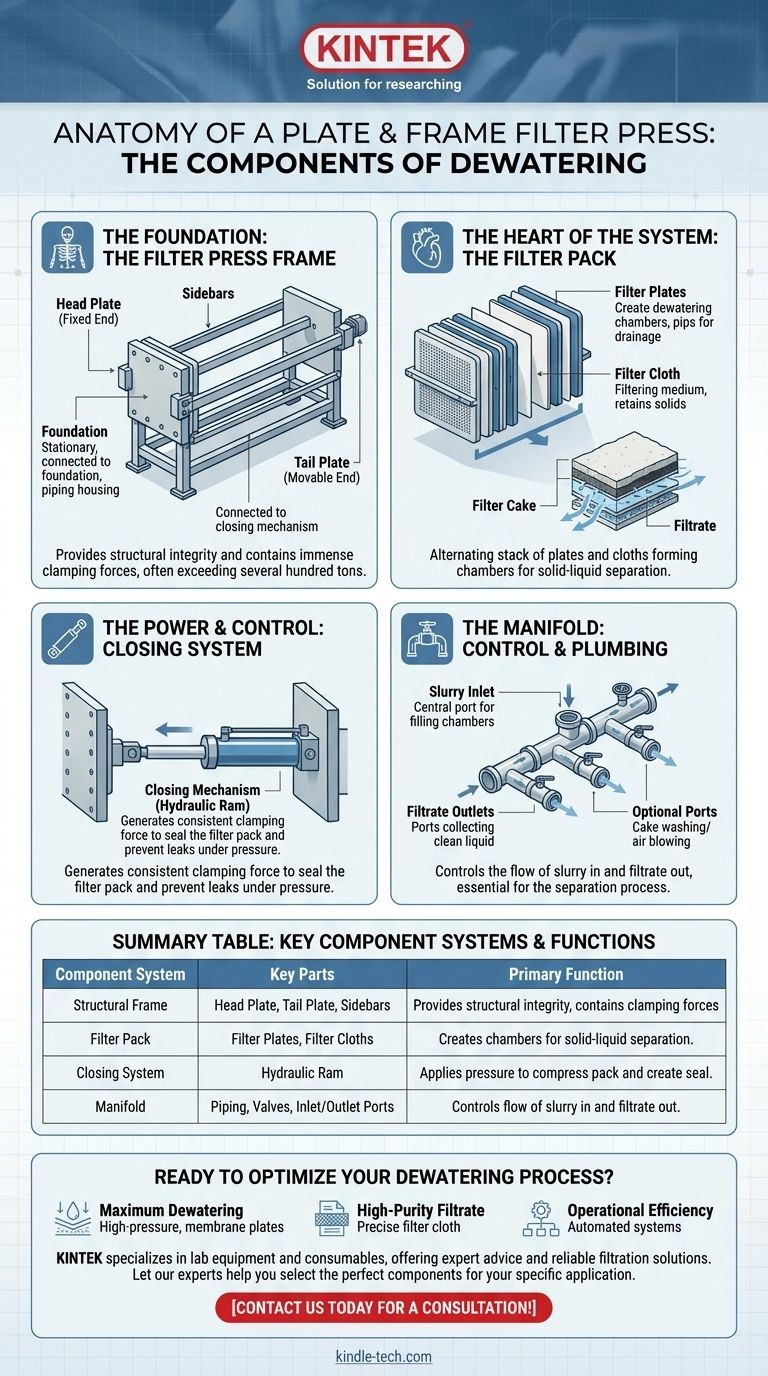

At its core, a plate and frame filter press consists of four primary systems. These are the structural frame that holds everything together, the filter pack (plates and cloths) that performs the separation, the closing system that applies pressure, and the manifold that controls the flow of liquid. Each component is engineered to work in concert under immense force to effectively separate solids from liquids.

A filter press is not merely a collection of parts; it is a precisely engineered system. The frame provides the structural integrity, the plates and cloth create the dewatering chambers, and the hydraulic and manifold systems provide the force and control that drive the entire separation process.

The Foundation: The Filter Press Frame

The frame is the skeleton of the machine. It provides the structural support necessary to contain the immense clamping forces required for filtration, which can often exceed several hundred tons.

The Head Plate (Fixed End)

This is the stationary anchor of the filter press. It is fixed to the foundation and houses the primary piping connections for the slurry feed and the filtrate (clean liquid) discharge.

The Tail Plate (Movable End)

This component moves along the sidebars to open and close the filter pack. It is directly connected to the closing mechanism, transmitting the clamping force across the stack of filter plates.

The Sidebars

These are the heavy-duty rails, typically made of solid steel, that connect the head and tail plates. The filter plates hang from and slide along these bars, which must be strong enough to resist bending under the full clamping pressure.

The Heart of the System: The Filter Pack

The filter pack is where the actual work of separation happens. It is a stack of alternating filter plates and filter cloths, which form a series of chambers.

The Filter Plates

The role of the filter plates is to create the empty chambers where the solids, known as "filter cake," accumulate. When pressed together, the recesses in adjoining plates form these sealed chambers. The plate surfaces have drainage patterns (often called pips) that allow the filtered liquid to flow away behind the filter cloth.

The Filter Cloth

This is the true filtering medium. Each filter plate is dressed with a sheet of filter cloth, which is a finely woven fabric (often polypropylene). The cloth retains the solid particles on its surface while allowing the clean liquid to pass through its pores and exit via the drainage channels in the plate.

How the Pack is Assembled

The filter pack is an alternating series of plates and cloths. This stack is compressed tightly between the head and tail plates, creating a series of sealed, empty chambers ready to be filled with slurry.

The Power and Control: Closing and Manifold Systems

These systems provide the force to seal the press and the pathways to move liquid in and out. Without them, the filtration process could not occur.

The Closing Mechanism

This is the system that generates the clamping force. On most industrial presses, this is a large hydraulic ram that pushes the tail plate forward, compressing the filter pack. The hydraulic system ensures a consistent and powerful seal to prevent leaks under high feed pressure.

The Manifold and Piping

The manifold is the "plumbing" of the press. It is a system of pipes and valves that controls the flow of material:

- Slurry Inlet: A central port where the slurry is pumped into the filter pack, filling all the chambers simultaneously.

- Filtrate Outlets: Ports that collect the clean, filtered liquid after it has passed through the filter cloths.

- Optional Ports: Many presses include additional connections for processes like cake washing or air blowing, which help to further purify or dry the filter cake.

Understanding the Trade-offs

Choosing the right components involves balancing performance, cost, and operational requirements. The two most critical choices are the plate design and the filter media.

Plate Type: Plate-and-Frame vs. Recessed Chamber

The term "plate and frame" technically refers to an older design with a flat plate alternating with a hollow frame. However, the modern recessed chamber plate is far more common. Recessed plates are simpler, seal more effectively, and are less labor-intensive, making them the standard for most applications today.

Filter Cloth Selection

This is the single most critical decision for performance. The cloth's material, weave, and micron rating must be precisely matched to the slurry's particle size, temperature, and chemical composition. An incorrect choice leads to poor filtration, cloth "blinding" (clogging), or premature failure.

Level of Automation

Presses can range from fully manual, where an operator physically moves each plate, to fully automated systems with automatic plate shifters, cloth washers, and cake discharge mechanisms. The correct choice depends entirely on the required cycle time, labor costs, and initial capital investment.

Making the Right Choice for Your Goal

The ideal configuration of your filter press depends entirely on your primary objective.

- If your primary focus is maximum dewatering: You need a high-pressure hydraulic system and may want to invest in membrane squeeze plates, which can apply additional pressure to the cake to remove more liquid.

- If your primary focus is high-purity filtrate: The filter cloth is your most critical component. Invest in a high-quality cloth with the precise micron rating and weave to prevent solids from bypassing the filter.

- If your primary focus is operational efficiency: Prioritize an automatic plate shifter and a well-designed, automated manifold to minimize cycle times and reduce manual labor requirements.

Understanding how these individual components function as a cohesive system is the first step toward mastering your dewatering process.

Summary Table:

| Component System | Key Parts | Primary Function |

|---|---|---|

| Structural Frame | Head Plate, Tail Plate, Sidebars | Provides structural integrity and contains immense clamping forces. |

| Filter Pack | Filter Plates, Filter Cloths | Creates chambers where solid-liquid separation occurs. |

| Closing System | Hydraulic Ram | Applies pressure to compress the filter pack and create a seal. |

| Manifold | Piping, Valves, Inlet/Outlet Ports | Controls the flow of slurry in and filtrate (clean liquid) out. |

Ready to optimize your dewatering process? The right filter press configuration is critical for achieving maximum dewatering, high-purity filtrate, or operational efficiency. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert advice and reliable filtration solutions. Let our experts help you select the perfect components for your specific application. Contact us today for a consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming