To properly handle an electrolytic cell after use, you must follow a strict sequence of operations. First, always turn off the power supply completely before disconnecting any part of the circuit. Next, safely remove and manage the electrolyte based on its chemical properties, and finally, thoroughly clean and dry all components to prevent corrosion and ensure the integrity of future experiments.

The core principle behind post-electrolysis procedures is not just cleanup, but a systematic shutdown designed to ensure operator safety, preserve the longevity of your equipment, and eliminate cross-contamination that could compromise your next experiment.

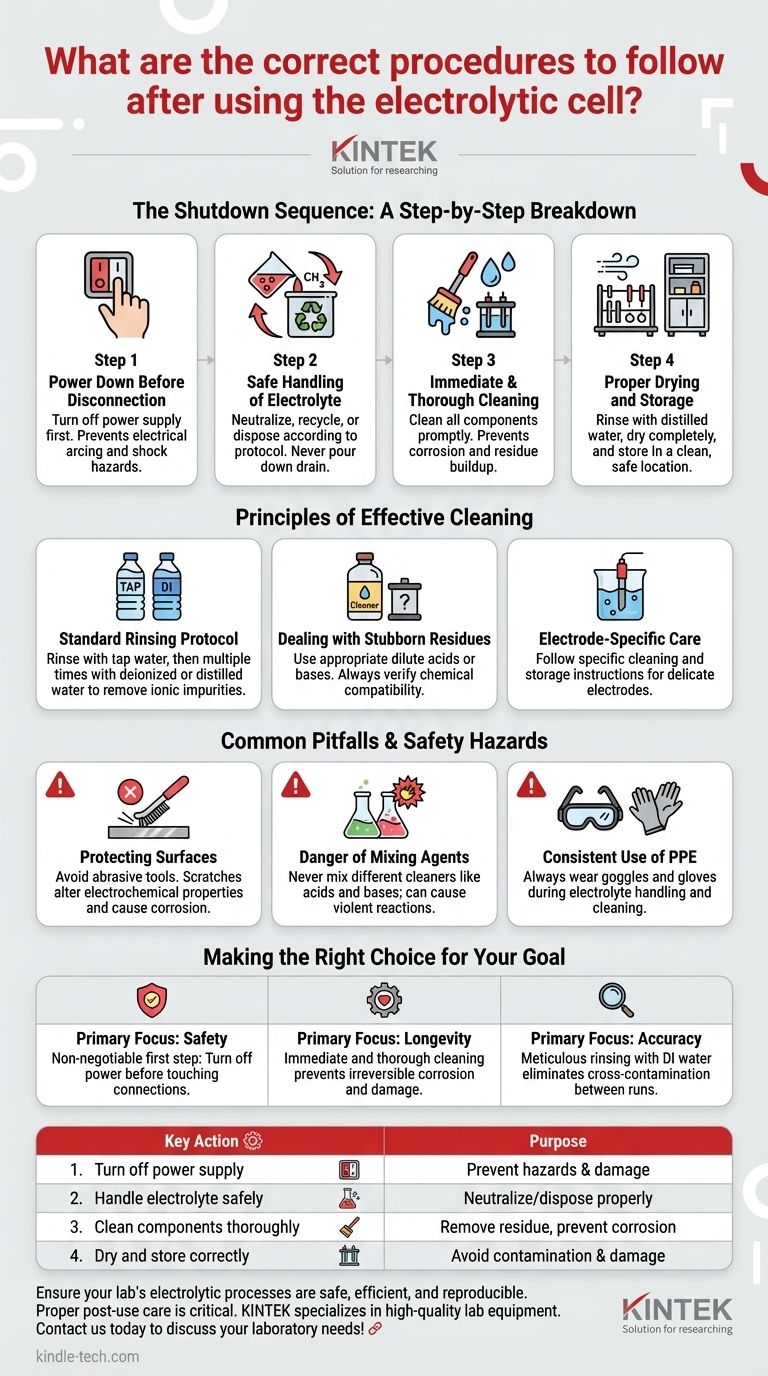

The Shutdown Sequence: A Step-by-Step Breakdown

Following a precise order of operations is critical for both safety and the preservation of your equipment. Each step is designed to mitigate a specific risk, from electrical hazards to chemical corrosion.

Step 1: Power Down Before Disconnection

The absolute first step is to turn off the power supply. Only after the power is off should you disconnect the circuit or remove the electrodes.

This sequence prevents the risk of electrical arcing between connection points, which can damage equipment and pose a significant electrical shock hazard.

Step 2: Safe Handling of the Electrolyte

Once the system is de-energized, you must address the electrolyte. The correct method depends entirely on its chemical composition.

This may involve neutralization for acidic or basic solutions, recycling for valuable materials, or disposal according to established laboratory and environmental safety protocols. Never pour reactive chemicals down the drain without proper treatment.

Step 3: Immediate and Thorough Cleaning

Promptly clean the electrolytic cell, electrodes, and all other components. Delaying this step allows residual electrolyte and reaction products to corrode surfaces or solidify, making them difficult to remove.

The goal is to eliminate any residue that could interfere with future reactions or degrade the equipment over time.

Step 4: Proper Drying and Storage

After a final rinse with distilled or deionized water, allow all parts to dry completely.

Store the cleaned cell and electrodes in a dry, clean, and safe location. This prevents contamination from dust and moisture and protects delicate components, like electrodes, from physical damage.

Principles of Effective Cleaning

A proper cleaning protocol is essential for maintaining the accuracy and reproducibility of your work. Contamination is a primary source of experimental error.

The Standard Rinsing Protocol

Begin by rinsing the cell and its components with tap water to remove the bulk of the electrolyte and product.

Follow this with multiple rinses using deionized or distilled water. This second step is crucial for removing any remaining ionic impurities that could affect subsequent experiments.

Dealing with Stubborn Residues

For stubborn stains or product buildup, you may need a more aggressive cleaning agent. This could be a dilute acid or base, depending on the nature of the residue.

Crucially, you must select a cleaner that will not corrode or damage the cell body or the electrodes. Always verify chemical compatibility before use.

Electrode-Specific Care

Electrodes are often the most sensitive and expensive components. Carefully disassemble them and clean them according to their specific instructions.

Some electrodes must be stored in a dedicated solution to maintain their integrity, while others simply need to be kept clean and dry.

Common Pitfalls and Safety Hazards

Mistakes during shutdown and cleaning can be costly and dangerous. Awareness of common errors is the best way to prevent them.

Protecting Equipment Surfaces

Never use abrasive tools like metal brushes for cleaning. These will inevitably scratch the interior surfaces of the cell and the electrodes, which can alter their electrochemical properties and create sites for corrosion.

The Danger of Mixing Cleaning Agents

Avoid mixing different cleaning chemicals, especially acids and bases. Combining reagents like nitric acid (HNO₃) and sodium hydroxide (NaOH) can cause a violent exothermic reaction, creating a serious safety hazard.

Consistent Use of PPE

The need for personal protective equipment does not end when the power is off. Continue to wear safety goggles and gloves throughout the electrolyte handling and cleaning process to protect against chemical splashes and skin contact.

Making the Right Choice for Your Goal

Adhering to the correct procedure ensures that your equipment remains reliable and your lab environment stays safe. Your primary motivation will determine which steps you emphasize.

- If your primary focus is safety: The non-negotiable first step is always turning off the power supply before touching any connections.

- If your primary focus is equipment longevity: Immediate and thorough cleaning after every use is the best way to prevent irreversible corrosion and damage.

- If your primary focus is experimental accuracy: Meticulous rinsing with deionized water and proper storage are essential to eliminate cross-contamination between runs.

Mastering this post-experiment workflow is fundamental to producing safe, consistent, and reliable results.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Turn off power supply | Prevent electrical hazards and equipment damage |

| 2 | Handle electrolyte safely | Neutralize, recycle, or dispose of chemicals properly |

| 3 | Clean components thoroughly | Remove residue and prevent corrosion |

| 4 | Dry and store correctly | Avoid contamination and physical damage |

Ensure your lab's electrolytic processes are safe, efficient, and reproducible. Proper post-use care is critical for equipment longevity and experimental accuracy. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools you need for consistent results. Let our experts help you optimize your workflow and maintain your investment. Contact us today to discuss your laboratory needs!

Visual Guide

Related Products

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What are the standard opening specifications for sealed and unsealed all-quartz electrolytic cells? Optimize Your Electrochemistry Setup

- What is the proper procedure for post-experiment cleanup and storage of an all-quartz electrolytic cell? Ensure Longevity and Reproducibility

- What are the necessary steps to prepare an all-quartz electrolytic cell before an experiment? Ensure Accuracy and Safety

- What are the primary applications of the all-quartz electrolytic cell? Essential for High-Purity & Optical Analysis

- Why is a quartz electrolytic cell used for acrylic acid wastewater? Ensure Chemical Stability & Data Integrity