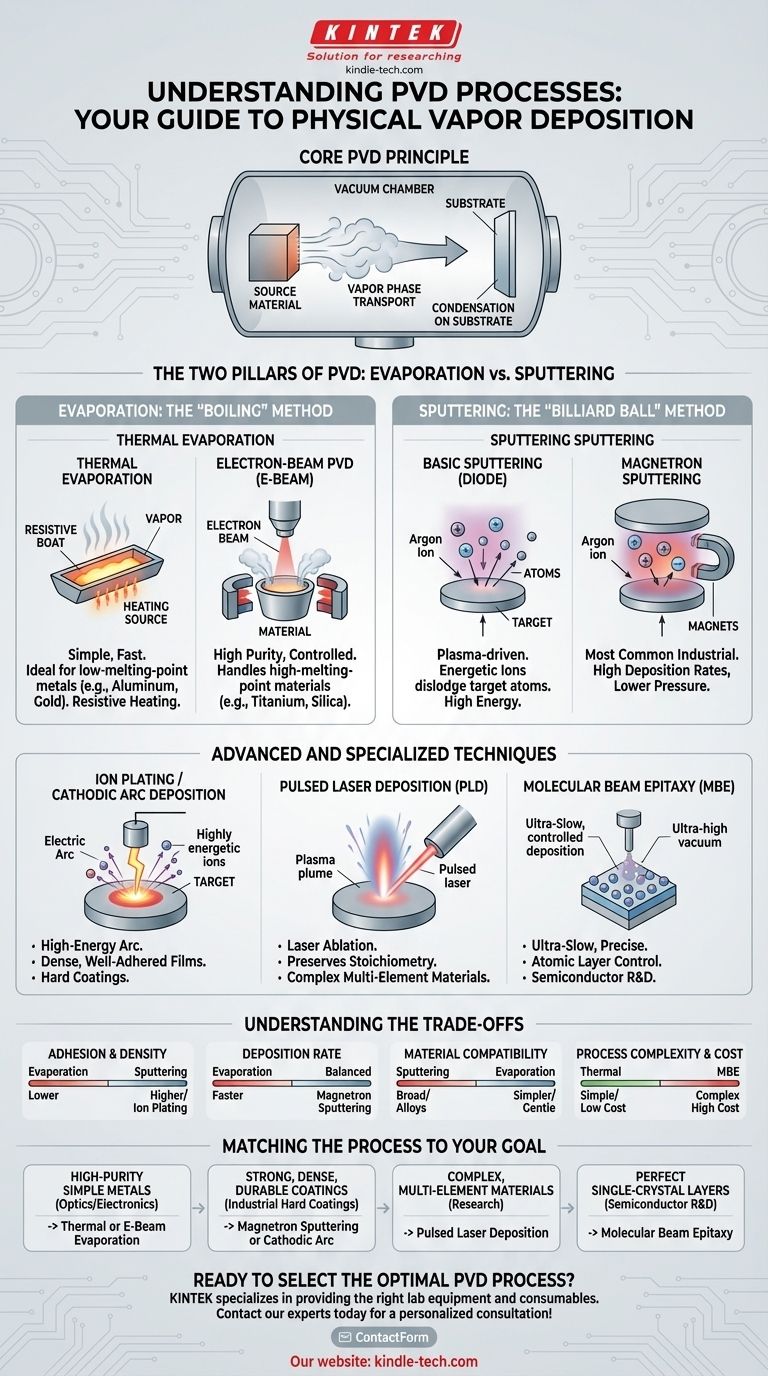

At its core, Physical Vapor Deposition (PVD) is a family of vacuum deposition methods where a material is transformed into a vapor phase, transported across a vacuum chamber, and condensed onto a substrate to form a thin film. The primary categories of PVD are Evaporation and Sputtering, with more specialized techniques like Ion Plating and Pulsed Laser Deposition serving specific applications.

The choice between PVD processes is not about which is universally "best," but which method provides the optimal energy, control, and material properties for your specific goal. Understanding the physical mechanism of each technique—whether it's gently "boiling" a material or kinetically "blasting" it—is the key to selecting the right tool.

The Two Pillars of PVD: Evaporation vs. Sputtering

All PVD processes physically move material from a source (the target) to a destination (the substrate) without a chemical reaction. The fundamental difference lies in how they liberate atoms from that source.

Evaporation: The "Boiling" Method

Evaporation involves heating a source material in a vacuum until it vaporizes. These vaporized atoms then travel in a straight line until they condense on the cooler substrate, forming a film.

Thermal Evaporation

This is the simplest form. A high electrical current is passed through a resistive boat or filament containing the source material, heating it until it evaporates. It's fast and effective for pure, low-melting-point metals like aluminum or gold.

Electron-Beam PVD (E-Beam PVD)

For materials with very high melting points (like titanium or silica), a high-energy electron beam is magnetically guided to strike and heat the source material. This method offers higher purity and greater control than basic thermal evaporation.

Sputtering: The "Billiard Ball" Method

Sputtering uses a high-energy plasma to physically eject atoms from the target. Imagine a stream of heavy billiard balls (ions) striking a rack of balls (the target), knocking individual ones loose to land on the substrate.

Basic Sputtering (Diode Sputtering)

An inert gas, typically argon, is introduced into the vacuum chamber and ionized to create a plasma. A high voltage is applied to the target, causing the positive argon ions to accelerate and bombard it, dislodging atoms that then deposit onto the substrate.

Magnetron Sputtering

This is the most common industrial PVD process. Powerful magnets are placed behind the target to trap electrons near its surface. This dramatically increases the efficiency of ion formation in the plasma, leading to much higher deposition rates and lower operating pressures.

Advanced and Specialized PVD Techniques

Beyond the two main pillars, several specialized methods exist for advanced applications requiring unique film properties.

Ion Plating / Cathodic Arc Deposition

These are high-energy processes that create a very dense, well-adhered film. In Cathodic Arc Deposition, a high-current electric arc moves across the target surface, vaporizing and ionizing the material directly. The resulting ions are highly energetic, leading to superior coating density and adhesion, ideal for hard coatings on cutting tools.

Pulsed Laser Deposition (PLD)

A high-power pulsed laser is focused on the target in a vacuum. Each pulse ablates (blasts away) a tiny amount of material, creating a plasma plume that deposits onto the substrate. PLD is exceptional for depositing complex materials with multiple elements, as it can preserve the material's original stoichiometry (elemental ratio).

Molecular Beam Epitaxy (MBE)

MBE is a highly refined form of thermal evaporation conducted under ultra-high vacuum conditions. It allows for extremely slow and controlled deposition, literally building a film one atomic layer at a time. This precision is essential for fabricating complex, single-crystal structures for semiconductors and advanced research.

Understanding the Trade-offs

No single PVD process is perfect for every task. The choice involves balancing competing factors.

Film Adhesion and Density

Sputtering and Ion Plating produce highly energetic atoms, resulting in dense films with excellent adhesion to the substrate. Evaporation is a lower-energy process, which can result in less dense films with weaker adhesion unless substrate heating is used.

Deposition Rate and Throughput

Evaporation processes are generally faster than sputtering, making them suitable for applications like metallizing large batches of parts. Magnetron Sputtering offers a good balance of speed and film quality for industrial-scale coating.

Material and Substrate Compatibility

Sputtering can deposit virtually any material, including alloys and compounds. However, the energetic bombardment can damage sensitive substrates. Evaporation is gentler on the substrate but can be difficult for alloys, as the constituent elements may evaporate at different rates.

Process Complexity and Cost

Thermal evaporation systems are relatively simple and inexpensive. In contrast, MBE systems are extraordinarily complex and expensive, reflecting their high-precision capabilities. Magnetron sputtering sits in the middle, offering a robust industrial solution at a moderate cost.

Matching the Process to Your Goal

Your application dictates the optimal PVD technique.

- If your primary focus is high-purity films of simple metals for optics or electronics: Thermal or E-beam Evaporation is your most direct and efficient choice.

- If your primary focus is strong, dense, and durable films for industrial hard coatings: Magnetron Sputtering or Cathodic Arc Deposition provides the required adhesion and resilience.

- If your primary focus is depositing complex, multi-element materials for research: Pulsed Laser Deposition offers unmatched ability to preserve the material's original composition.

- If your primary focus is creating perfect, single-crystal semiconductor layers: Molecular Beam Epitaxy is the only process that offers the necessary atomic-level control.

Understanding the fundamental physics behind each method empowers you to select the process that will reliably and efficiently produce the film properties you need.

Summary Table:

| Process | Primary Mechanism | Key Characteristics | Ideal For |

|---|---|---|---|

| Thermal Evaporation | Resistive heating of source material | Fast, simple, high purity for simple metals | Optics, electronics metallization |

| E-Beam PVD | Electron beam heating of source | High purity, handles high-melting-point materials | High-purity metal films |

| Magnetron Sputtering | Plasma bombardment of target (most common) | Dense films, excellent adhesion, good for alloys | Industrial hard coatings, durable films |

| Cathodic Arc Deposition | High-current electric arc on target | Very dense films, superior adhesion | Extreme-wear applications (e.g., cutting tools) |

| Pulsed Laser Deposition (PLD) | Laser ablation of target | Preserves complex material stoichiometry | Research, multi-element materials |

| Molecular Beam Epitaxy (MBE) | Ultra-slow thermal evaporation | Atomic-layer control, ultra-high vacuum | Semiconductor R&D, single-crystal films |

Ready to Select the Optimal PVD Process for Your Lab?

Choosing the right Physical Vapor Deposition technique is critical for achieving the desired film properties—whether you need superior adhesion for a hard coating or atomic-level precision for semiconductor research. KINTEK specializes in providing the right lab equipment and consumables to meet your specific PVD application needs.

We understand that your research and production goals demand reliable, high-performance solutions. Our expertise can help you navigate the trade-offs between evaporation, sputtering, and advanced techniques to ensure you get the density, purity, and throughput required for success.

Let's discuss your project requirements and find the perfect PVD solution for your laboratory.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition