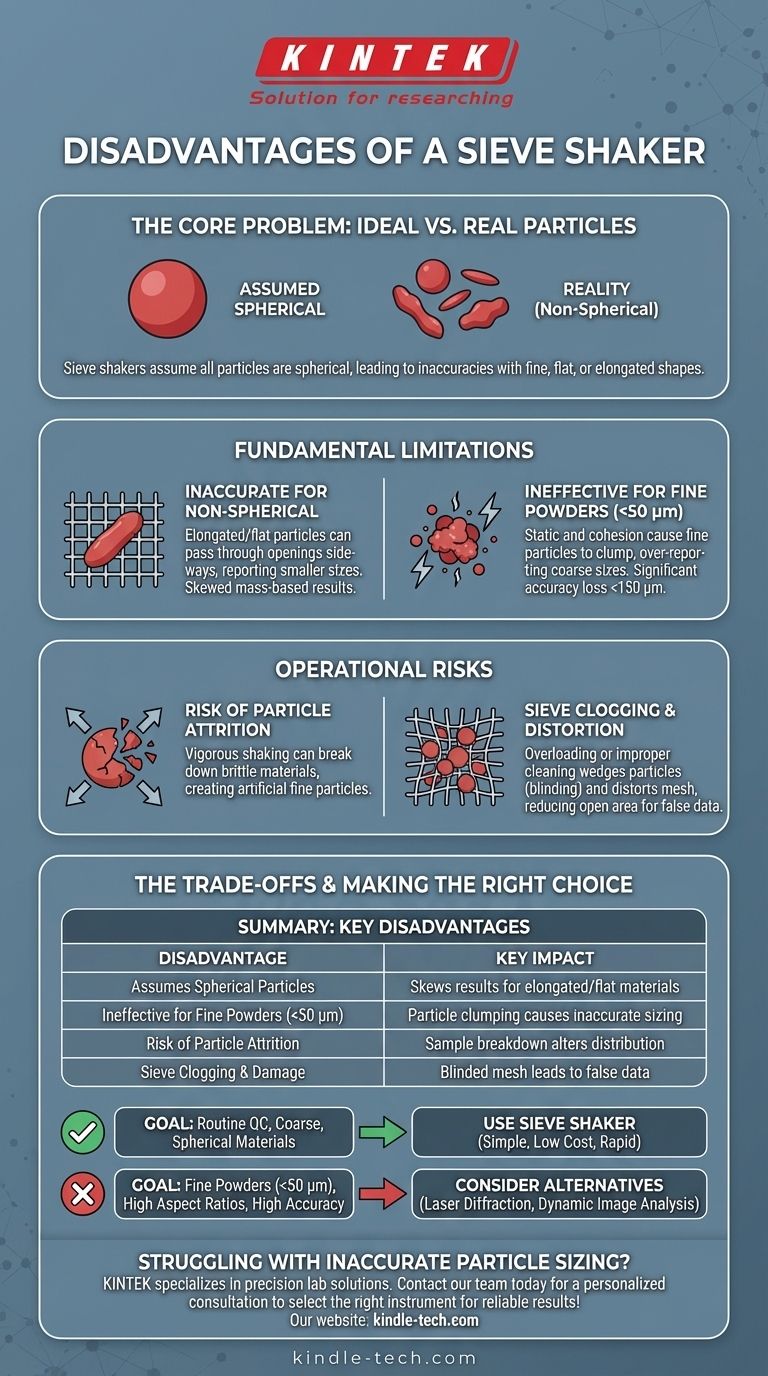

At its core, a sieve shaker's main disadvantages stem from its fundamental assumption: that all particles are perfect spheres. While simple and cost-effective, this mechanical sorting method struggles with accuracy when dealing with very fine, flat, or elongated particles, leading to results that may not reflect the true particle size distribution. Its effectiveness is also limited to a specific particle size range, and it is prone to operational errors if not maintained correctly.

A sieve shaker's simplicity is both its greatest strength and its primary weakness. It provides a reliable, low-cost solution for basic particle sizing but falters when precision is required for non-spherical particles or powders finer than approximately 50 microns (µm).

The Fundamental Limitations of Mechanical Sieving

A sieve shaker operates on a straightforward principle: shaking a stack of screens with progressively smaller mesh openings to separate particles by size. This mechanical process, however, introduces several inherent limitations that you must understand to ensure accurate analysis.

The Problem of Particle Shape

A sieve shaker fundamentally measures a particle's second-largest dimension. An elongated or flat particle can pass through a mesh opening end-on or sideways, even if its longest dimension is much larger than the opening.

This creates a significant discrepancy. The analysis assumes particles are spherical, but in reality, needle-like or flaky materials are reported as being much smaller than they actually are. This leads to unreliable mass-based results and a skewed understanding of your sample.

Inaccuracy with Fine Powders

Sieve shakers are generally unsuitable for particles smaller than 50 µm and lose significant accuracy with materials finer than 100 mesh (approximately 150 µm).

At these small scales, forces like static electricity and surface cohesion cause fine particles to clump together. This prevents them from passing through the mesh correctly, leading to an over-reporting of coarse particle sizes.

Understanding the Operational Risks

Beyond its fundamental limitations, a sieve shaker's performance is highly dependent on proper operation and maintenance. Failure to adhere to best practices can introduce significant errors into your results.

Risk of Particle Attrition

The very action that makes a sieve shaker work—vigorous shaking—can also damage the sample. The constant collision of particles can cause brittle materials to break down, an effect known as attrition or size reduction.

This process creates more fine particles than were originally present, skewing the distribution and defeating the purpose of the analysis.

Sieve Clogging and Distortion

Overloading a sieve or failing to clean it properly can lead to particles becoming wedged in the mesh openings, a phenomenon called clogging or blinding. This effectively reduces the open area of the sieve, preventing other particles from passing through.

Furthermore, improper handling or cleaning can damage or distort the delicate wire mesh. Any deviation from the specified opening size renders the sieve, and any analysis performed with it, inaccurate.

The Trade-offs: Simplicity vs. Precision

The decision to use a sieve shaker involves a clear trade-off. It is an excellent tool for many applications, but it is not a universal solution for particle size analysis.

Where Sieve Shakers Excel

Sieve shakers are valued for their simplicity, low cost, and rapid results. For quality control applications involving coarse, relatively spherical materials (like grains, sand, or plastic pellets), they provide accurate and reproducible data with minimal operator training.

When to Consider Alternatives

If your analysis involves very fine powders (<50 µm), materials with high aspect ratios (needles or flakes), or requires the highest degree of accuracy, a sieve shaker is likely the wrong tool. More advanced methods, such as laser diffraction or dynamic image analysis, are designed to overcome the geometric limitations of sieving, though they come at a higher cost and complexity.

Making the Right Choice for Your Goal

To determine if a sieve shaker is appropriate, you must first define the goal of your analysis and the nature of your material.

- If your primary focus is routine quality control of coarse, free-flowing materials: A sieve shaker is a cost-effective and reliable choice that will deliver consistent results.

- If your primary focus is analyzing fine powders or materials prone to static: A sieve shaker is unsuitable and you should investigate alternative analysis methods.

- If your primary focus is high-precision characterization of elongated or flat particles: A sieve shaker will provide skewed data, and you must use a method that directly measures particle shape.

Ultimately, understanding these disadvantages empowers you to select the right tool for the job and interpret your results with confidence.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Assumes Spherical Particles | Skews results for elongated/flat materials |

| Ineffective for Fine Powders (<50 µm) | Particle clumping causes inaccurate sizing |

| Risk of Particle Attrition | Sample breakdown during shaking alters distribution |

| Sieve Clogging & Damage | Blinded or distorted mesh leads to false data |

Struggling with inaccurate particle sizing? Your material's unique properties demand the right equipment. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision solutions. Let our experts help you select the perfect instrument—whether it's a robust sieve shaker for quality control or a more advanced analyzer for fine powders. Contact our team today for a personalized consultation and achieve reliable, reproducible results!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What are the advantages and disadvantages of sieve analysis? A Guide to Cost-Effective Particle Sizing

- What are the different methods of sieving? Choose the Right Technique for Your Material

- Which Cannot be separated by sieving? Understanding the Limits of Particle Size Separation

- What can be separated by sieving? A Guide to Particle Size Separation for Various Materials

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis