The primary disadvantages of ceramic fiber are its poor physical durability and the health risks associated with handling its dust. The material is susceptible to damage from physical contact, high-velocity air, and chemical erosion, and its fibers can cause significant skin and respiratory irritation during installation.

While ceramic fiber offers exceptional thermal insulation, its effectiveness is offset by its physical fragility and a critical need for proper personal protective equipment (PPE) during handling and installation.

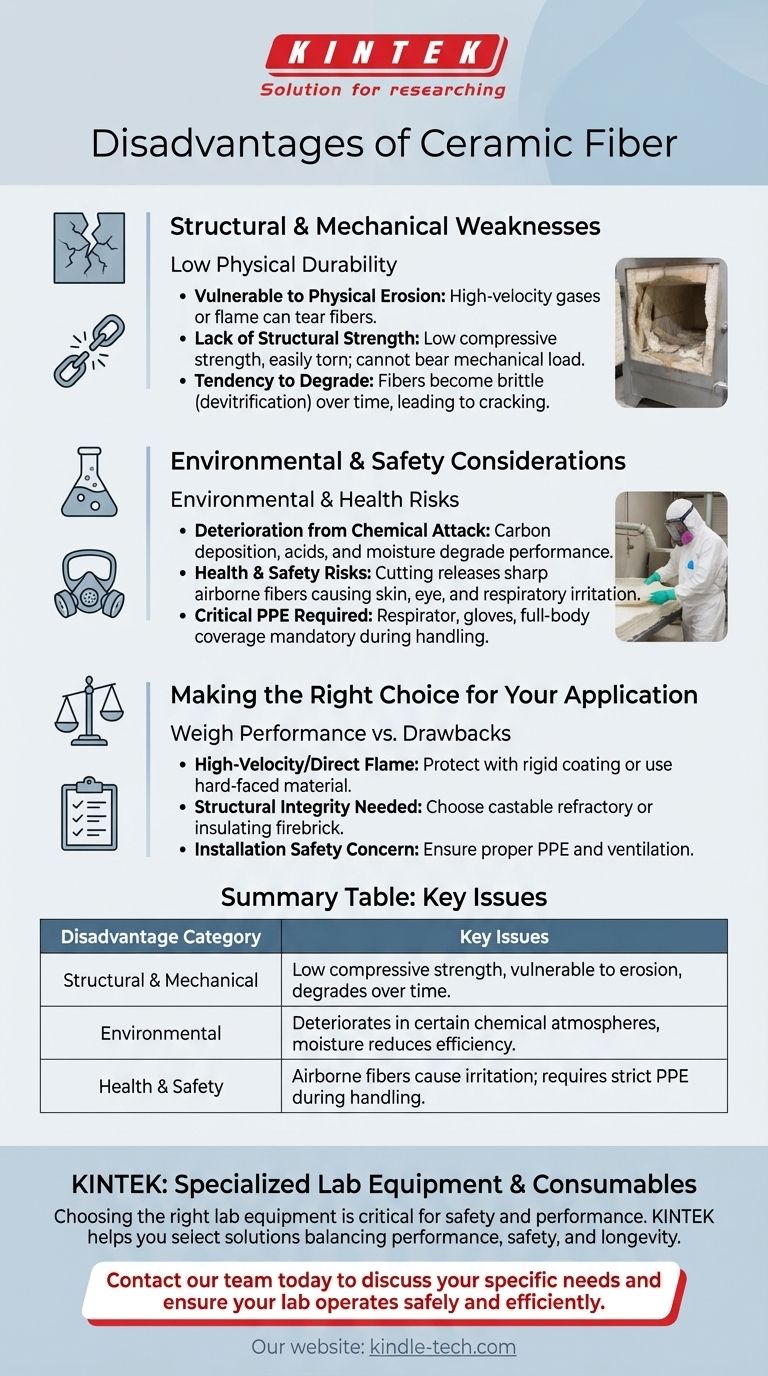

Structural and Mechanical Weaknesses

Ceramic fiber's greatest strength—its low density and fibrous nature—is also the source of its primary physical weaknesses. It is an insulator, not a structural material.

Vulnerability to Physical Erosion

The intertwined fibers are easily damaged. High-velocity gas flow or direct flame impingement can tear the fibers away, degrading the insulation and releasing particles into the environment.

This makes it unsuitable for the "hot face" in furnaces or forges with aggressive burner flows unless it is protected by a rigidizer or a hard refractory coating.

Lack of Structural Strength

Ceramic fiber has very low compressive strength and can be easily torn or punctured. It cannot bear any mechanical load and will compact over time if subjected to pressure or vibration, creating thermal weak spots.

Its stability depends heavily on proper installation, often requiring mechanical support like ceramic anchors to prevent sagging or detachment.

Tendency to Degrade

Over time and with repeated thermal cycles, the fibers can become brittle. This process, known as devitrification, reduces the material's flexibility and can lead to cracking or peeling away from its backing.

Environmental and Safety Considerations

Beyond its physical limitations, ceramic fiber performance is highly dependent on its operating environment and demands careful handling procedures.

Deterioration from Chemical Attack

Certain chemical atmospheres can degrade ceramic fibers. For example, carbon deposition in reducing atmospheres can cause the fibers to break down, compromising their insulating properties.

It is also susceptible to attack from certain acids and is not suitable for applications where it might become wet, as moisture severely reduces its thermal efficiency.

Health and Safety Risks

This is a critical consideration. Cutting or handling ceramic fiber releases small, sharp fibers into the air.

These airborne particles can cause significant skin itchiness, eye irritation, and throat and lung irritation if inhaled. Proper PPE, including a respirator, gloves, and full-body coverage, is non-negotiable during installation or removal.

Making the Right Choice for Your Application

You must weigh the material's excellent insulating capacity against its significant handling and durability drawbacks.

- If your application involves high-velocity gases or direct flame impingement: Plan to protect the ceramic fiber with a rigid refractory coating or use a denser, hard-faced material instead.

- If your project requires any structural integrity from the insulator: Ceramic fiber is the wrong choice; consider a castable refractory or insulating firebrick.

- If your primary concern is installation safety: Ensure you have the proper PPE (respirator, safety glasses, gloves) and adequate ventilation before starting any work.

Understanding these limitations is the key to using ceramic fiber effectively and safely.

Summary Table:

| Disadvantage Category | Key Issues |

|---|---|

| Structural & Mechanical | Low compressive strength, vulnerable to erosion, degrades over time (devitrification) |

| Environmental | Deteriorates in certain chemical atmospheres, moisture reduces thermal efficiency |

| Health & Safety | Airborne fibers cause skin and respiratory irritation; requires strict PPE during handling |

Choosing the right lab equipment is critical for safety and performance.

KINTEK specializes in providing durable and safe laboratory equipment and consumables. If you're evaluating insulation materials for your furnace or thermal application, our experts can help you select a solution that balances performance with safety and longevity.

Contact our team today to discuss your specific needs and ensure your lab operates safely and efficiently.

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Thermally Evaporated Tungsten Wire for High Temperature Applications

People Also Ask

- What insulating materials can tolerate maximum temperature? Select the Right High-Temp Insulator for Your Application

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car

- Why are platinum electrode wires wrapped in oxidized zirconia coils? Ensure Signal Integrity in High-Temp Systems

- What is the role of zirconia fiber felt in Si2N2O synthesis? Ensuring Thermal Efficiency and Electrical Safety

- Can ceramic withstand high temperatures? Discover the Superior Materials for Extreme Heat