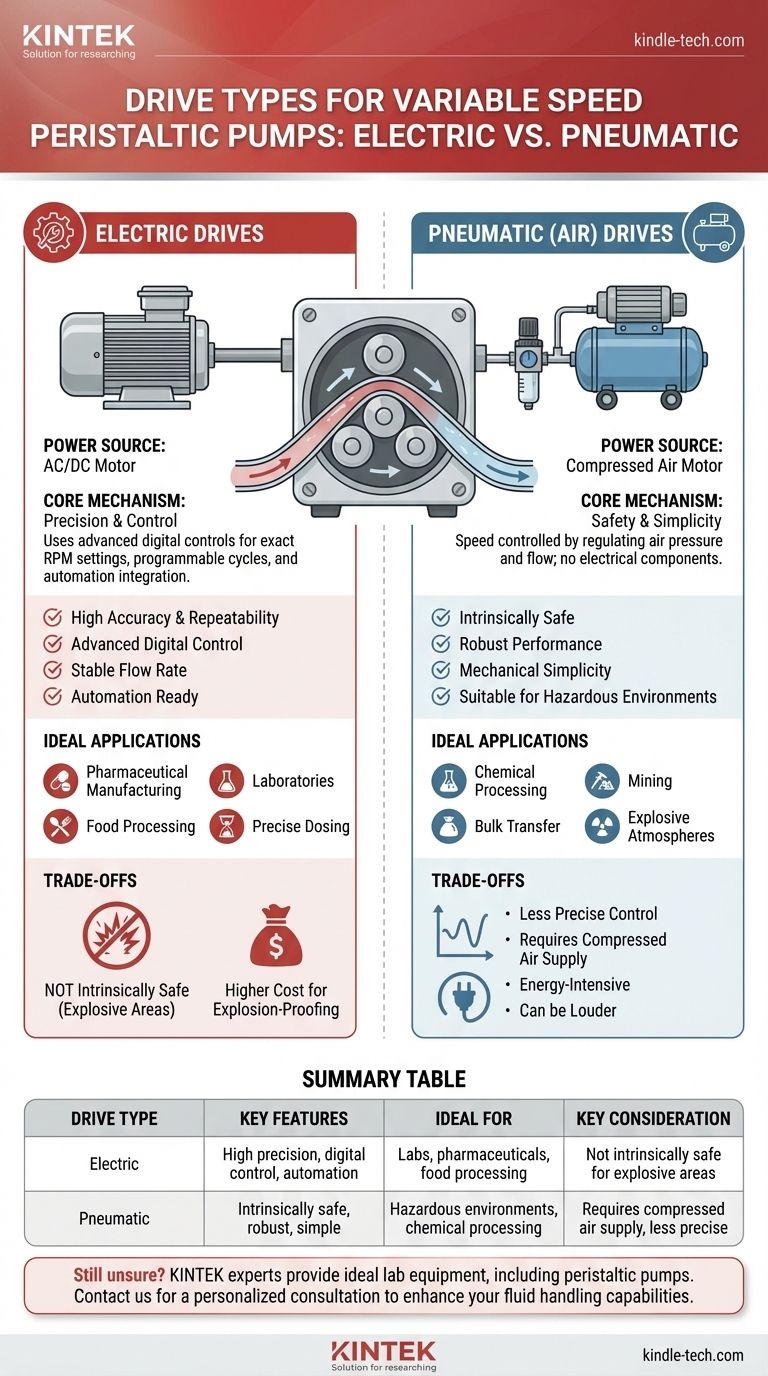

In short, variable speed peristaltic pumps are powered by two main types of drives: electric and pneumatic. The selection is determined by the specific requirements of your operating environment, the precision needed for your application, and the available power sources.

The choice between an electric or pneumatic drive is not about which is universally "better," but which is fundamentally suited to your operational context. The decision hinges on balancing the need for precise control against the demand for intrinsic safety.

Understanding the Core Drive Mechanisms

To select the right pump, you must first understand how each drive type functions and what inherent advantages it offers. These mechanisms are the foundation of the pump's performance characteristics.

Electric Drives: Precision and Control

Electric drives use an AC or DC motor to power the pump head. These are the most common drive type for peristaltic pumps due to their versatility and advanced control capabilities.

Modern electric drives often feature sophisticated digital controls, allowing for exact RPM settings, programmable dispensing cycles, and integration with larger automated systems. This makes them ideal for applications requiring high accuracy and repeatability.

You will find electric drives in environments like pharmaceutical manufacturing, laboratories, and food processing, where precise metering and sterile conditions are paramount.

Pneumatic (Air) Drives: Safety and Simplicity

Pneumatic drives use a compressed air motor instead of an electric one. The speed of the pump is controlled by regulating the pressure and flow of the air supplied to the drive.

Their primary advantage is intrinsic safety. Because they have no electrical components that can spark, they are the default choice for hazardous or explosive environments, such as in chemical processing or mining.

While they offer variable speed, the control is typically less precise than a high-end digital electric drive. However, their mechanical simplicity often translates to robust performance and easier maintenance in harsh industrial settings.

How Drive Type Influences Pump Performance

The drive is the "brain and muscle" of the pump. Its design directly dictates the level of control you can achieve and how the pump integrates into your overall process.

The Role of the Control System

Advanced electric drives are often computer-controlled. This enables features like digital displays for immediate feedback, remote start/stop capabilities, and communication with process controllers (e.g., via 4-20mA or Profibus).

Pneumatic drive control is more straightforward, typically involving a manual air regulator to adjust motor speed. While less suited for complex automation, this simplicity is a key benefit where manual operation is sufficient.

Flow Rate Stability and Range

Digital electric drives provide an exceptionally stable and repeatable flow rate once set. They can maintain a precise speed across a wide operational range, from very low to maximum RPM.

Pneumatic drives also offer a good range of speed adjustment, but their flow rate can be more susceptible to fluctuations in the plant's air supply pressure. They are excellent for bulk transfer but may be less suitable for ultra-precise micro-dosing.

Understanding the Trade-offs

Choosing a drive system always involves balancing competing priorities. Objectively evaluating the downsides of each option is critical for making a sound technical decision.

The Electric Drive Dilemma: Environment and Cost

The primary limitation of a standard electric drive is that it is not safe for explosive atmospheres. To be used in such an environment, it requires a costly and bulky explosion-proof enclosure, which significantly increases the total system price.

The Pneumatic Drive Limitation: Infrastructure and Efficiency

A pneumatic drive is only an option if you have a reliable and appropriately sized compressed air system. Generating compressed air is an energy-intensive process, and these systems can be less energy-efficient than a direct electric motor. They also tend to be louder during operation.

Making the Right Choice for Your Application

Your final decision should be guided by the primary goal of your specific process. Consider the following scenarios to clarify your choice.

- If your primary focus is high-precision dosing and automation: A digital electric drive is the superior choice for its accuracy, repeatability, and system integration capabilities.

- If your primary focus is safety in a hazardous or explosive environment: A pneumatic drive is the inherently safer and more cost-effective solution.

- If your primary focus is simple, general-purpose fluid transfer in a safe area: A basic analog electric drive often provides the best balance of performance and cost.

Ultimately, matching the drive's inherent characteristics to your operational needs ensures reliable, safe, and efficient performance.

Summary Table:

| Drive Type | Key Features | Ideal For | Key Consideration |

|---|---|---|---|

| Electric | High precision, digital control, automation | Labs, pharmaceuticals, food processing | Not intrinsically safe for explosive areas |

| Pneumatic | Intrinsically safe, robust, simple | Hazardous environments, chemical processing | Requires compressed air supply, less precise |

Still unsure which drive type is right for your process? The experts at KINTEK are here to help. We specialize in providing the ideal lab equipment, including peristaltic pumps, to meet your specific needs for precision, safety, and efficiency.

Contact us today for a personalized consultation and discover how KINTEK can enhance your laboratory's fluid handling capabilities.

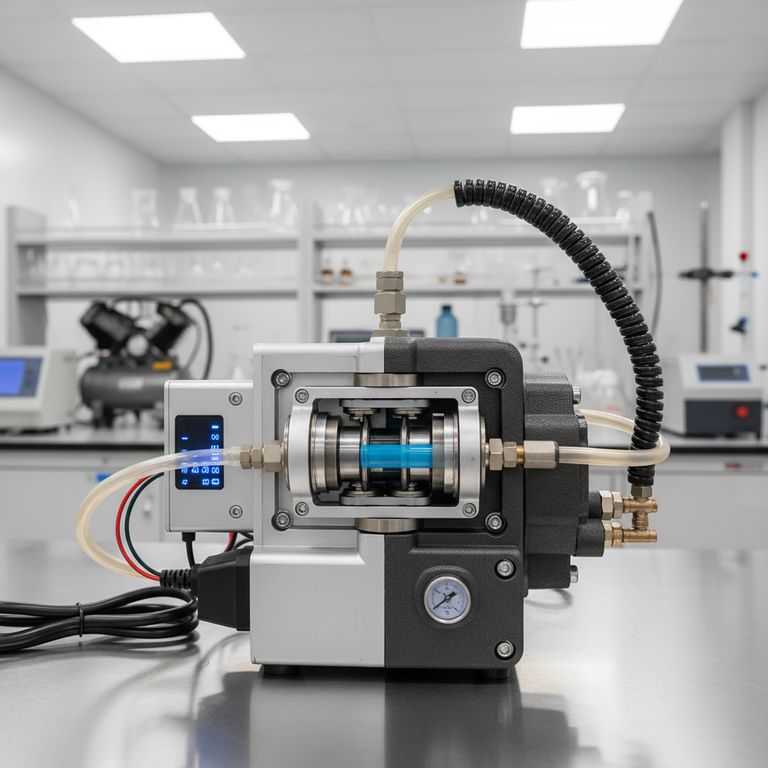

Visual Guide

Related Products

- Variable Speed Peristaltic Pump

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the primary function of a vacuum pump? Remove Gas Molecules to Create a Controlled Vacuum

- What is the role of the constant flow and constant pressure pump in core flooding? Master Deep Granite Stimulation

- Why is a water circulating vacuum pump suitable for handling flammable or explosive gases? Inherent Safety Through Isothermal Compression

- How do you inspect a vacuum pump? A Step-by-Step Guide to Ensure Peak Performance

- How does a laboratory peristaltic pump contribute to the continuous operation of an electrochemical flow cell?