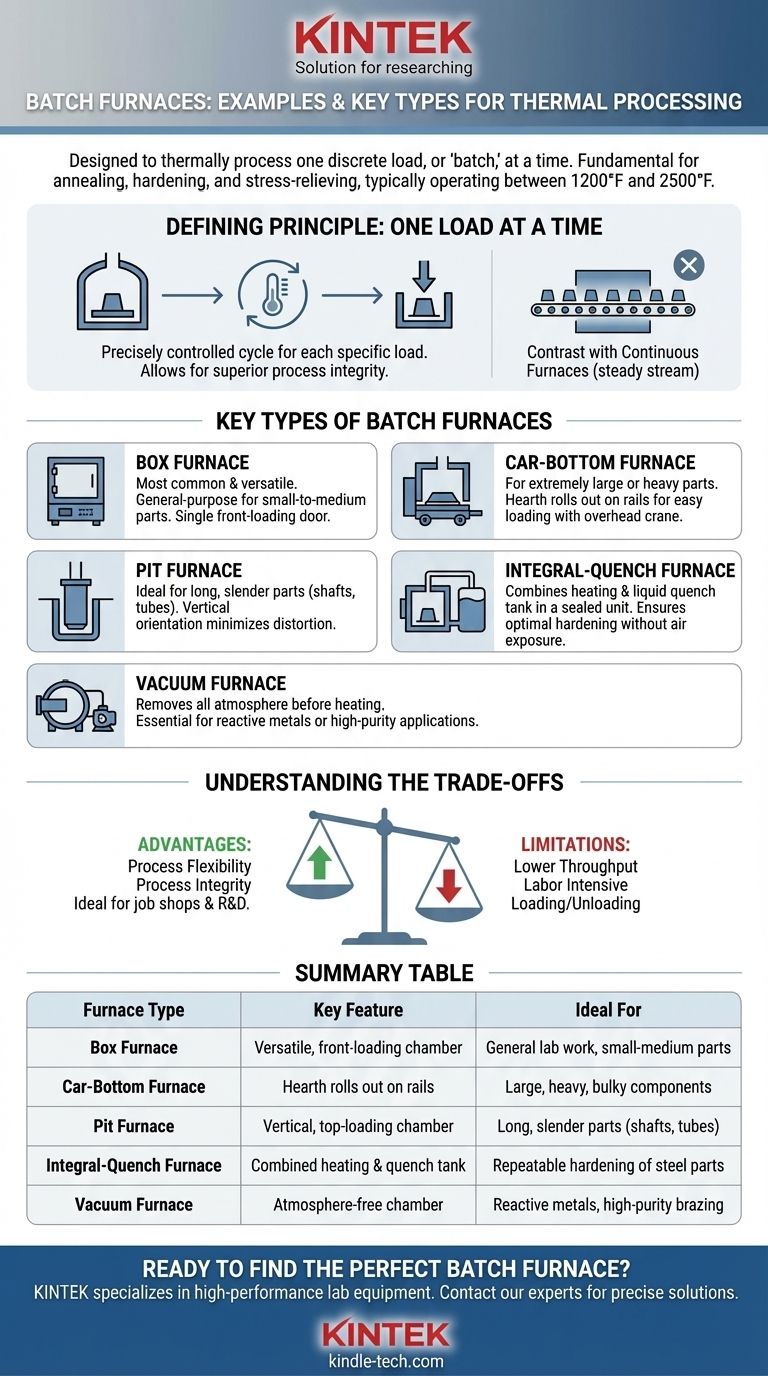

Common examples of batch furnaces include the box furnace, car-bottom furnace, pit furnace, and integral-quench furnace. These units are designed to thermally process materials one discrete load, or "batch," at a time. Often operating at temperatures between 1200°F and 2500°F, they are fundamental tools for heat treatments like annealing, hardening, and stress-relieving across numerous industries.

The term 'batch furnace' describes a method of thermal processing—heating a single, defined load at a time—rather than one specific design. The right type of batch furnace is chosen based on the part's size, the volume of production, and the specific atmospheric and thermal requirements of the process.

The Defining Principle of Batch Processing

A batch furnace is fundamentally different from a continuous furnace, which processes a steady stream of material. This batch-by-batch approach offers distinct advantages for specific applications.

Core Concept: One Load at a Time

The defining characteristic is its operational cycle: load the material, run the heating (and cooling) process from start to finish, and then unload the material. This allows for precise control over the thermal profile for each specific load.

Key Function: Controlled Heat Treatment

Batch furnaces are workhorses for a vast range of thermal processes. This includes ageing, annealing (softening), brazing, hardening, sintering (fusing powder into a solid), and tempering (improving toughness).

Critical Feature: Atmosphere Control

Many advanced processes cannot tolerate the presence of oxygen at high temperatures. Batch furnaces excel at creating controlled environments, with two common types being protective atmosphere furnaces and vacuum furnaces, which prevent oxidation and other unwanted chemical reactions.

Key Types of Batch Furnaces Explained

While all operate on the batch principle, their physical designs are tailored for different needs.

Box Furnace

The box furnace is the most common and versatile design, essentially a temperature-controlled box with a single front-loading door. It is the go-to choice for general-purpose lab work and heat-treating a wide variety of small- to medium-sized parts.

Car-Bottom Furnace

For extremely large or heavy parts, the car-bottom furnace is ideal. Its entire hearth (floor) is mounted on a "car" that rolls out on rails. This allows heavy components to be loaded directly onto the hearth with an overhead crane before being rolled into the furnace chamber.

Pit Furnace

A pit furnace is a cylindrical chamber installed vertically in a pit in the facility floor. Parts are loaded from the top using a hoist. This design is perfect for long, slender parts like shafts or tubes, as vertical orientation minimizes sagging and distortion during heating.

Integral-Quench Furnace

Also known as a "sealed quench" furnace, this is a more complex system that combines the heating chamber and a liquid quench tank (typically oil) into a single, sealed unit. After heating, the load is automatically moved to the quench tank without ever being exposed to outside air, ensuring optimal hardening and a clean surface finish.

Vacuum Furnace

A vacuum furnace is a specialized type that removes all atmosphere from the chamber before heating. This is the ultimate form of atmosphere control, essential for processing highly reactive metals (like titanium) or for high-purity applications like brazing in the aerospace and medical industries.

Understanding the Trade-offs

Choosing a batch furnace involves balancing flexibility against production volume.

Advantage: Process Flexibility

Batch furnaces are unmatched in their flexibility. You can run completely different parts with different heating cycles back-to-back, making them perfect for job shops, research and development, and high-mix, low-volume production.

Advantage: Process Integrity

For sensitive applications, the sealed nature of many batch designs (especially integral-quench and vacuum) provides superior process control and integrity compared to many continuous designs.

Limitation: Lower Throughput

The primary drawback is lower throughput. The cycle of loading, heating, cooling, and unloading is inherently less efficient for mass-producing identical parts than a continuous furnace, where parts are always moving through.

Limitation: Labor and Handling

Batch processing often requires more manual intervention for loading and unloading each batch, whereas continuous systems are more easily automated for high-volume production.

Making the Right Choice for Your Application

Your specific goal will determine the ideal furnace configuration.

- If your primary focus is general-purpose lab work or heat-treating varied parts: A box furnace offers the most versatility and cost-effectiveness.

- If your primary focus is processing very large, heavy, or bulky components: A car-bottom furnace is designed for easy loading and uniform heating of massive parts.

- If your primary focus is preventing distortion in long, slender parts like shafts: A pit furnace provides the ideal vertical orientation to maintain straightness.

- If your primary focus is repeatable, high-quality hardening of steel parts: An integral-quench furnace delivers precise atmospheric control and immediate quenching in a single cycle.

- If your primary focus is brazing or treating reactive metals with zero contamination: A vacuum furnace is the only choice for ensuring an ultrapure processing environment.

Understanding these core designs empowers you to select the precise tool for your specific thermal processing needs.

Summary Table:

| Furnace Type | Key Feature | Ideal For |

|---|---|---|

| Box Furnace | Versatile, front-loading chamber | General lab work, small-medium parts |

| Car-Bottom Furnace | Hearth rolls out on rails | Large, heavy, bulky components |

| Pit Furnace | Vertical, top-loading chamber | Long, slender parts (shafts, tubes) |

| Integral-Quench Furnace | Combined heating & quench tank | Repeatable hardening of steel parts |

| Vacuum Furnace | Atmosphere-free chamber | Reactive metals, high-purity brazing |

Ready to find the perfect batch furnace for your lab's thermal processing needs? KINTEK specializes in high-performance lab equipment, including a full range of batch furnaces for annealing, hardening, brazing, and more. Our experts will help you select the right model—whether it's a versatile box furnace for R&D or a specialized vacuum furnace for sensitive materials—ensuring precise temperature control and process integrity. Contact our team today to discuss your application and get a personalized solution!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the strength of brazing aluminum? Achieve Robust, Leak-Tight Assemblies

- What is the precaution of furnace? Essential Safety Steps to Protect Operators and Equipment

- How does the heating rate in a nitriding furnace affect nitrogen diffusion? Optimize Layer Thickness and Quality

- What is the function of a vacuum drying oven in the preparation of succinimide anion-based ionic liquids?

- How does physical vapor deposition work? A Guide to High-Performance Thin Film Coating

- Do you quench before tempering? Master the Essential Sequence for Strong, Durable Steel

- How long does it take to heat treat metal? The 3 Stages That Dictate Your Timeline

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance