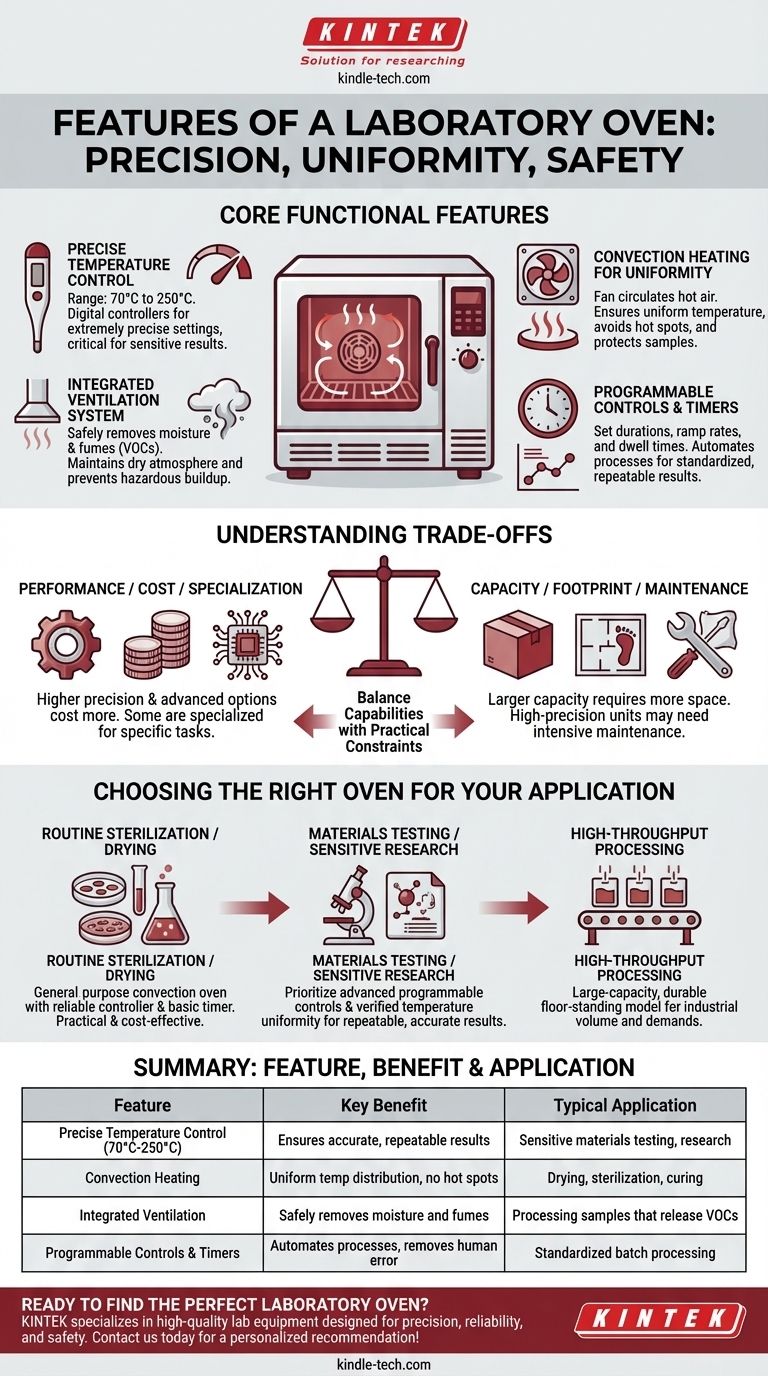

At its core, a laboratory oven is a specialized heating chamber designed for controlled, uniform, and safe thermal processing. Its key features include a precise temperature range, typically from 70°C to 250°C, convection heating for uniform temperature distribution without damaging samples, and an integrated vent to safely remove moisture and fumes generated during heating.

A laboratory oven is not simply a device that gets hot. It is an instrument of precision, where every feature is engineered to provide the stable, repeatable, and safe environment required for scientific applications like sterilization, drying, and materials testing.

Core Functional Features

The defining characteristics of a laboratory oven are not about raw power, but about control and consistency. These features ensure that scientific and industrial processes are both reliable and repeatable.

Precise Temperature Control

Laboratory ovens are built for accuracy. They operate within a specific range, often between 70°C and 250°C, with digital controllers that allow for extremely precise temperature settings.

This level of control is critical for experiments and processes where slight temperature deviations can invalidate results or damage sensitive materials.

Convection Heating for Uniformity

Most lab ovens use convection heating. A fan circulates hot air throughout the chamber, ensuring every part of the sample reaches a uniform temperature.

This method avoids "hot spots" and prevents direct radiant heat from scorching or damaging the surface of a sample, which is essential when drying delicate materials or sterilizing equipment.

Integrated Ventilation System

A crucial safety and performance feature is the exhaust vent. As samples are heated, they release moisture, volatile organic compounds (VOCs), or other fumes.

The vent allows these byproducts to escape the chamber. This not only maintains a dry internal atmosphere for efficient drying but also prevents a hazardous buildup of potentially flammable or corrosive fumes.

Programmable Controls and Timers

To ensure procedural standardization, modern ovens include programmable controllers and timers. Users can set specific heating durations, ramp-up rates, and dwell times.

This automates the process, removing human error and guaranteeing that every batch is treated under the exact same conditions, which is fundamental for reliable and comparable results.

Understanding the Trade-offs

Choosing a laboratory oven involves balancing capabilities with practical constraints. Not every feature is necessary for every task, and understanding the trade-offs is key to making a sound investment.

Performance vs. Cost

Higher-end ovens offer more precise temperature uniformity and advanced programming options. While essential for sensitive research, this precision comes at a significantly higher cost. For routine tasks like glassware drying, a simpler, more affordable model is often sufficient.

Capacity vs. Footprint

Ovens range from small benchtop units to large, floor-standing machines that can hold entire trolleys. While a higher capacity increases throughput, it also demands significant and often expensive laboratory floor space.

Specialization vs. Maintenance

Some ovens are robust workhorses designed for frequent, repetitive sterilization with minimal downtime. Others are delicate, high-precision instruments that may require more intensive maintenance and cleanup between uses to maintain their performance standards.

Choosing the Right Oven for Your Application

Your final choice should be dictated entirely by the specific tasks you need to perform. Consider the primary goal to select an oven with the right balance of features.

- If your primary focus is routine sterilization or drying: A general-purpose convection oven with a reliable temperature controller and basic timer is your most practical and cost-effective choice.

- If your primary focus is materials testing or sensitive research: Prioritize an oven with advanced programmable controls and verified temperature uniformity to ensure your results are repeatable and accurate.

- If your primary focus is high-throughput processing: A large-capacity, durable, floor-standing model is necessary to handle the volume and demands of an industrial or large-scale lab environment.

Understanding these core features empowers you to select not just an oven, but the correct instrument for achieving reliable scientific outcomes.

Summary Table:

| Feature | Key Benefit | Typical Application |

|---|---|---|

| Precise Temperature Control (70°C-250°C) | Ensures accurate, repeatable results | Sensitive materials testing, research |

| Convection Heating | Uniform temperature distribution, no hot spots | Drying, sterilization, curing |

| Integrated Ventilation | Safely removes moisture and fumes | Processing samples that release VOCs |

| Programmable Controls & Timers | Automates processes, removes human error | Standardized batch processing |

Ready to find the perfect laboratory oven for your application?

KINTEK specializes in providing high-quality lab equipment, including a wide range of laboratory ovens designed for precision, reliability, and safety. Whether you need a standard model for routine sterilization or a high-precision oven for sensitive research, our experts can help you select the ideal solution to enhance your lab's efficiency and ensure accurate results.

Contact us today to discuss your specific needs and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

People Also Ask

- How does a controlled drying process ensure the quality of radiochromic films? Achieve Precise Dosimetric Results

- What is the role of a blast drying oven in COF synthesis? Driving High-Crystallinity Solvothermal Reactions

- How does a laboratory constant temperature drying oven contribute to the processing of synthesized Zinc Oxide precipitates?

- Why is a laboratory-grade forced air drying oven required for alloy chip moisture analysis? Ensure Data Precision

- What is the function of a laboratory drying oven in Zr2.5Nb alloy pretreatment? Ensure Precise Corrosion Test Results